Corrosion-resistant coating reinforced drill rod and preparation method thereof

A corrosion-resistant coating and drill pipe technology, applied in the field of drilling tools and drill pipes, can solve problems such as poor corrosion resistance, and achieve the effects of good corrosion resistance, reduced damage, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Using vacuum melting high-pressure gas atomization powder making technology, put 95wt% pure nickel and 5wt% pure aluminum into the induction furnace, and after the metal is melted and refined, transfer the obtained melt into the heat preservation crucible for powder making The melt flows through the conduit and the nozzle and is atomized by the high-pressure gas flow to obtain 95Ni-5Al powder raw material.

[0054] Utilize the cold extrusion molding equipment with above-mentioned 95Ni-5Al raw material powder, extrude into wire by die, obtain the nickel-aluminum alloy wire material that the diameter that has obvious metallic luster is 3.0mm.

[0055] The raw material composition of Fe-based amorphous alloy powder is: Cr: 14wt%; Mo: 26wt%; B: 1.5wt%; Y: 4wt%; C: 4wt%;

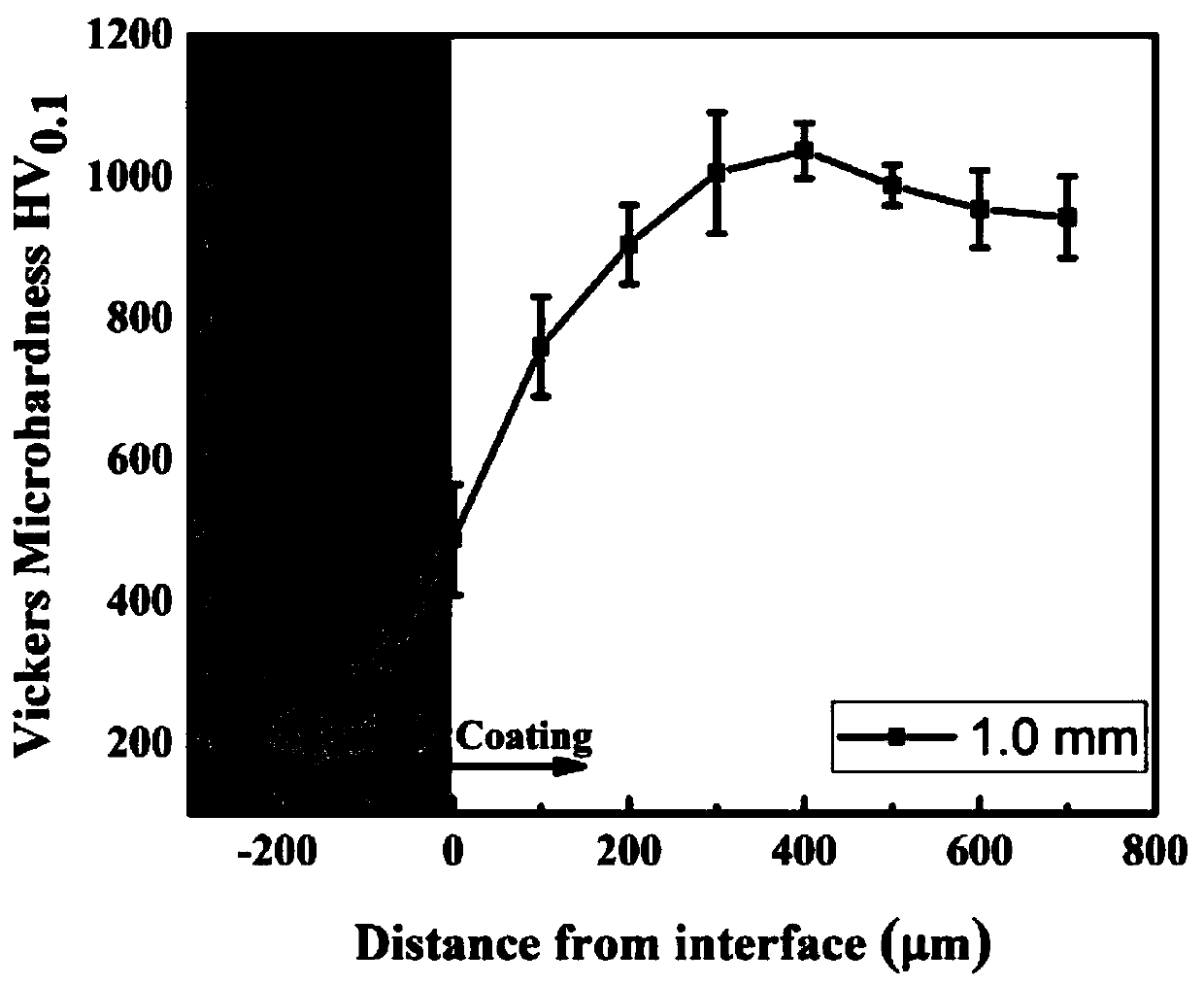

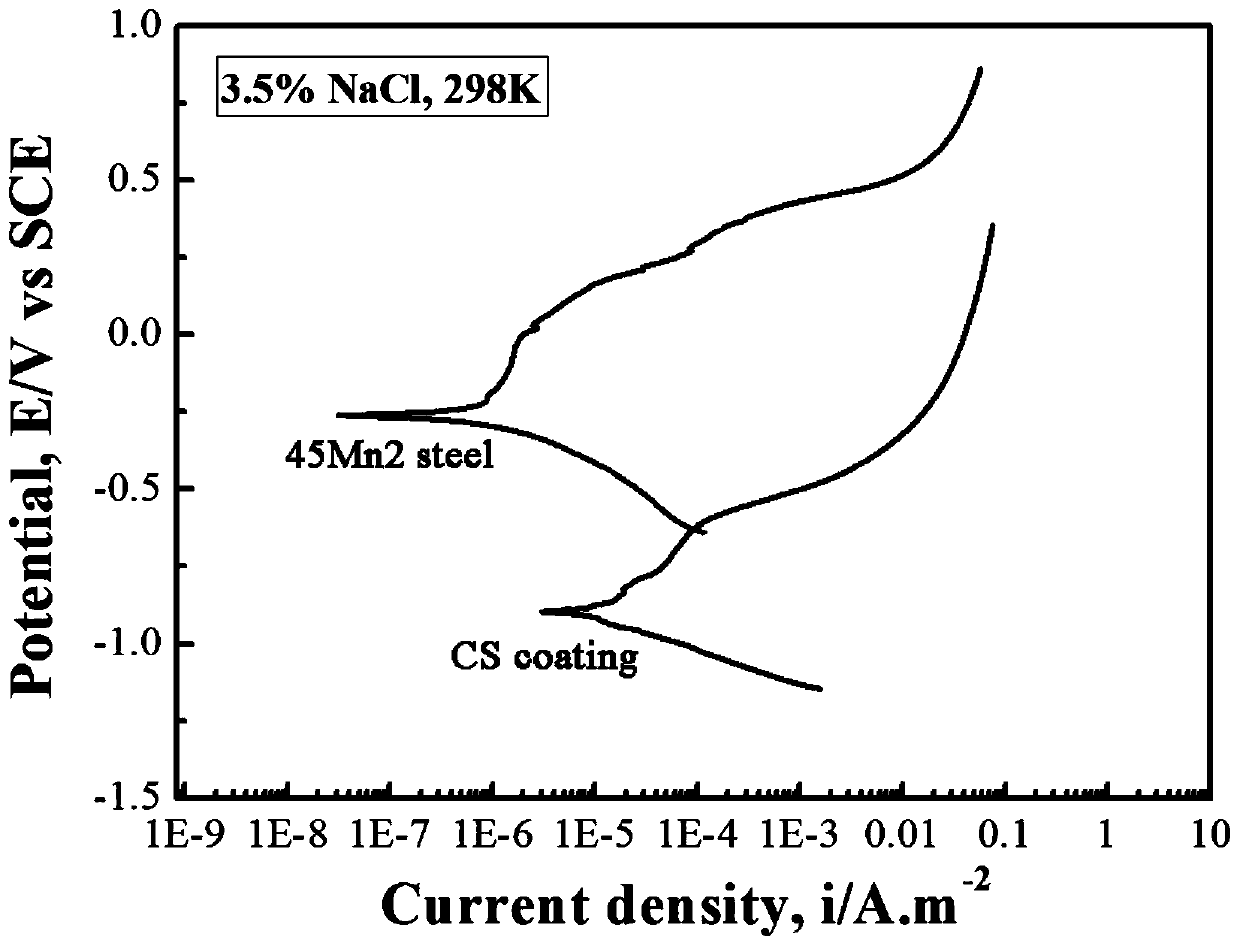

[0056] The 45Mn2 alloy steel pipe is used as the base of the drill pipe, and it is deoxidized, degreased, derusted and roughened by sandblasting in sequence, using corundum with a particle size of 250-800 ...

Embodiment 2

[0066] Using vacuum melting high-pressure gas atomization powder making technology, put 95wt% pure nickel and 5wt% pure aluminum into the induction furnace, and after the metal is melted and refined, transfer the obtained melt into the heat preservation crucible for powder making The melt flows through the conduit and the nozzle and is atomized by the high-pressure gas flow to obtain 95Ni-5Al powder raw material.

[0067] Utilize the cold extrusion molding equipment with above-mentioned 95Ni-5Al raw material powder, extrude into wire by die, obtain the nickel-aluminum alloy wire material that the diameter that has obvious metallic luster is 3.0mm.

[0068] The composition of Fe-based amorphous alloy powder raw material is: Cr: 13wt%; Mo: 25wt%; B: 1.0wt%; Y: 3wt%; C: 3wt%;

[0069] The 45Mn2 alloy steel pipe is used as the base of the drill pipe, and it is deoxidized, degreased, derusted and roughened by sandblasting in sequence, using corundum with a particle size of 250-800 ...

Embodiment 3

[0077] Using vacuum melting high-pressure gas atomization powder making technology, put 95wt% pure nickel and 5wt% pure aluminum into the induction furnace, and after the metal is melted and refined, transfer the obtained melt into the heat preservation crucible for powder making The melt flows through the conduit and the nozzle and is atomized by the high-pressure gas flow to obtain 95Ni-5Al powder raw material.

[0078] Utilize the cold extrusion molding equipment with above-mentioned 95Ni-5Al raw material powder, extrude into wire by die, obtain the nickel-aluminum alloy wire material that the diameter that has obvious metallic luster is 3.0mm.

[0079] The raw material composition of Fe-based amorphous alloy powder is: Cr: 15wt%; Mo: 27wt%; B: 2.0wt%; Y: 5wt%; C: 5wt%;

[0080]The 45Mn2 alloy steel pipe is used as the base of the drill pipe, and it is deoxidized, degreased, derusted and roughened by sandblasting in sequence, using corundum with a particle size of 250-800 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com