Preparation method of sodium phenylbutyrate

A technology of sodium phenylbutyrate and preparation, applied in the field of preparation of sodium phenylbutyrate, can solve the problems of low product yield, complicated post-processing purification process, many synthesis steps, etc. The effect of high regioselectivity and yield, and excessive resolution steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

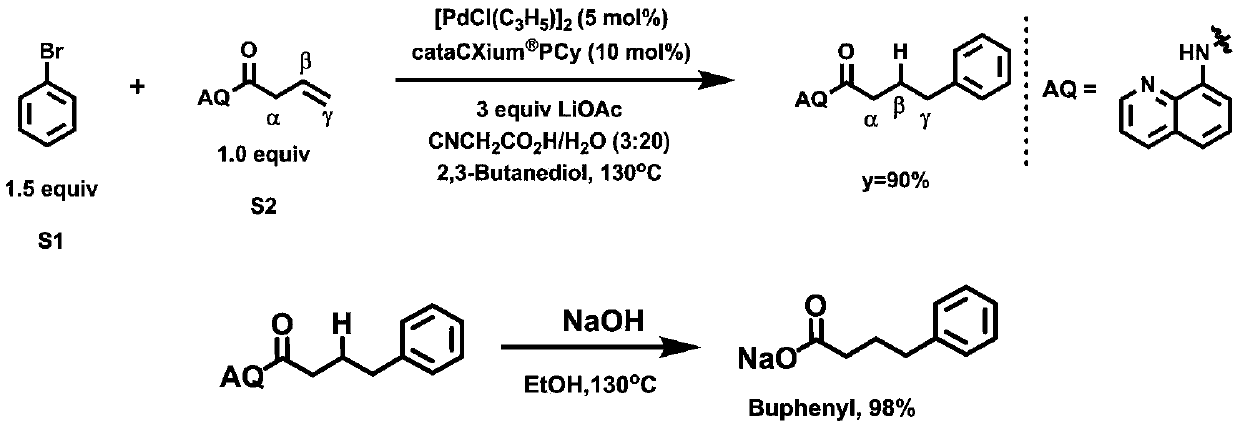

[0018] (1) Under an argon atmosphere, add the material and anhydrous 2,3-butanediol in a molar volume ratio of 0.1mmol:0.1mL to the reaction vessel and mix well; wherein, the related materials include a molar ratio of 1: 3:0.01:0.2:5:3:100 of N-(octaaminoquinoline)but-3-enamide, bromobenzene, allylpalladium(II) chloride dimer, 2-(dicyclohexylphosphine Acyl)-1-phenyl-1H-pyrrole, lithium acetate, cyanoacetic acid and water;

[0019] (2) Place the reaction vessel in an oil bath at 125°C and vigorously stir for 12 hours, and purify the reaction product through a silica gel column (flush the chromatography silica gel column with petroleum ether at a ratio of 1:20 to ethyl acetate), to obtain The compound is determined to be 4-phenyl-N-(quinolin-8-yl)butanamide through detection.

Embodiment 2

[0021] This embodiment is basically the same as Embodiment 1, the difference is:

[0022] In step (1), N-(octaaminoquinoline)but-3-enamide, bromobenzene, allylpalladium(II) chloride dimer, 2-(dicyclohexylphosphono)-1- The molar ratio of phenyl-1H-pyrrole, lithium acetate, cyanoacetic acid and water is 1:1:0.1:0.02:1:1:1;

[0023] In step (2), the temperature of the oil bath is 130°C.

Embodiment 3

[0025] This embodiment is basically the same as Embodiment 1, the difference is:

[0026] In step (1), N-(octaaminoquinoline)but-3-enamide, bromobenzene, allylpalladium(II) chloride dimer, 2-(dicyclohexylphosphono)-1- The molar ratio of phenyl-1H-pyrrole, lithium acetate, cyanoacetic acid and water is 1:2:0.05:0.1:3:2:50;

[0027] In step (2), the temperature of the oil bath is 135°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com