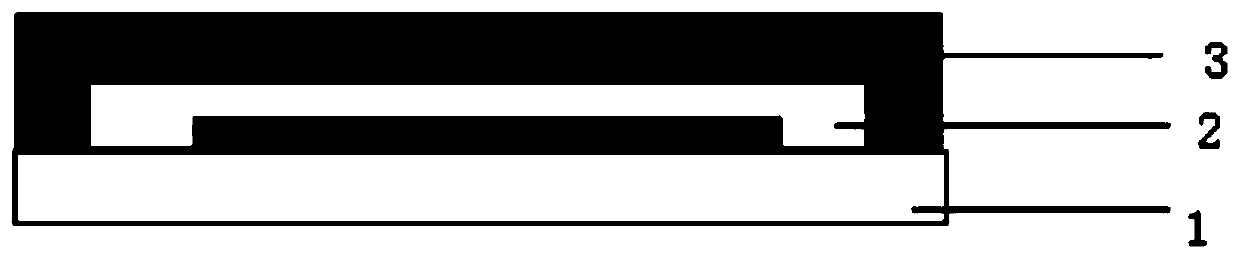

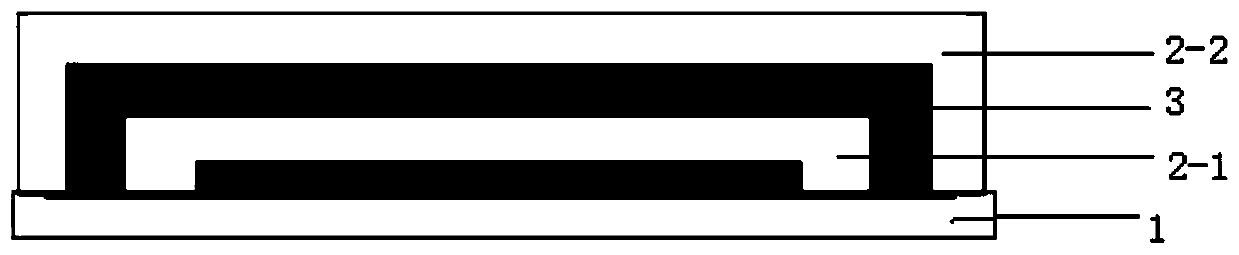

Organic polymer film for OLED (organic light emitting diode) device film packaging and application of organic polymer film

A polymer film and film encapsulation technology, which is applied in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve problems such as cracks and stress concentration of inorganic layers, achieve high transparency, improve flatness, and improve bending resistance The effect of foldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

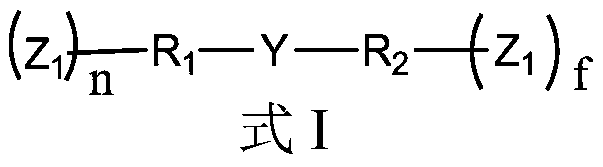

Method used

Image

Examples

Embodiment 1

[0062] Transparent ITO substrates were ultrasonically cleaned in isopropanol for 15 min and exposed to UV light for 30 min, followed by plasma treatment for 10 min. Then put the processed ITO substrate into the evaporation equipment. Put monomers A, B and initiator TPO into three evaporation crucibles, and then evaporate 5 ± 2 μm organic monomer film on the substrate, wherein A accounts for 75% of the total weight of the initiator and photocurable monomer, and B It accounts for 22% of the total weight of the initiator and the photocurable monomer, and the IPO accounts for 3% of the total weight of the initiator and the photocurable monomer. Then it was cured under 100mJ / cm2 of ultraviolet radiation for 10min to make it solidified.

Embodiment 2

[0064] Transparent ITO substrates were ultrasonically cleaned in isopropanol for 15 min and exposed to UV light for 30 min, followed by plasma treatment for 10 min. Then put the processed ITO substrate into the evaporation equipment. Put monomers A, B and initiator TPO into three evaporation crucibles, and then evaporate 5 ± 2 μm organic monomer film on the substrate, wherein A accounts for 75% of the total weight of the initiator and photocurable monomer, and B Accounting for 22% of the total weight of the initiator and the photocurable monomer, TPO accounts for 3% of the total weight of the initiator and the photocurable monomer. Then it was cured under 500mJ / cm2 ultraviolet radiation for 10min to make it solidified.

Embodiment 3

[0066] Transparent ITO substrates were ultrasonically cleaned in isopropanol for 15 min and exposed to UV light for 30 min, followed by plasma treatment for 10 min. Then put the processed ITO substrate into the evaporation equipment. Put monomers A, B and initiator TPO into 3 evaporation crucibles respectively, and then evaporate a 5 ± 2 μm organic monomer film on the substrate, wherein A accounts for 75% of the total weight of the initiator and photocurable monomer, B accounts for 22% of the total weight of the initiator and the photocurable monomer, and TPO accounts for 3% of the total weight of the initiator and the photocurable monomer. Then it was cured under 1000mJ / cm2 ultraviolet radiation for 10min to make it solidified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com