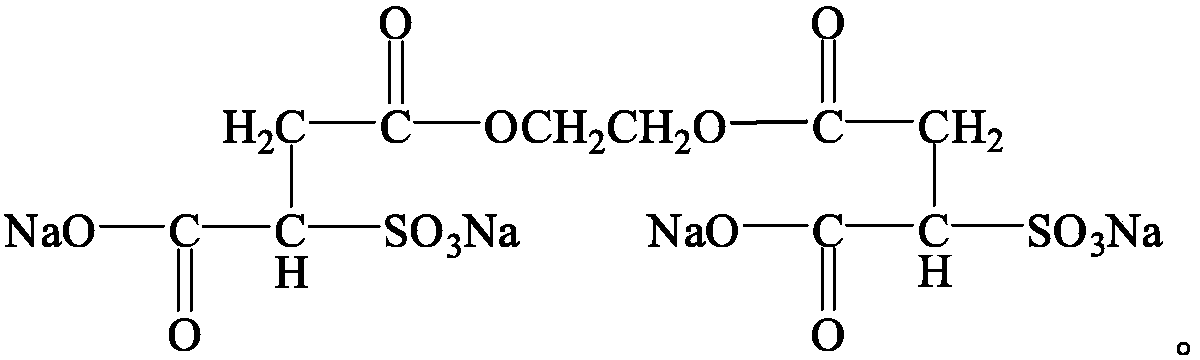

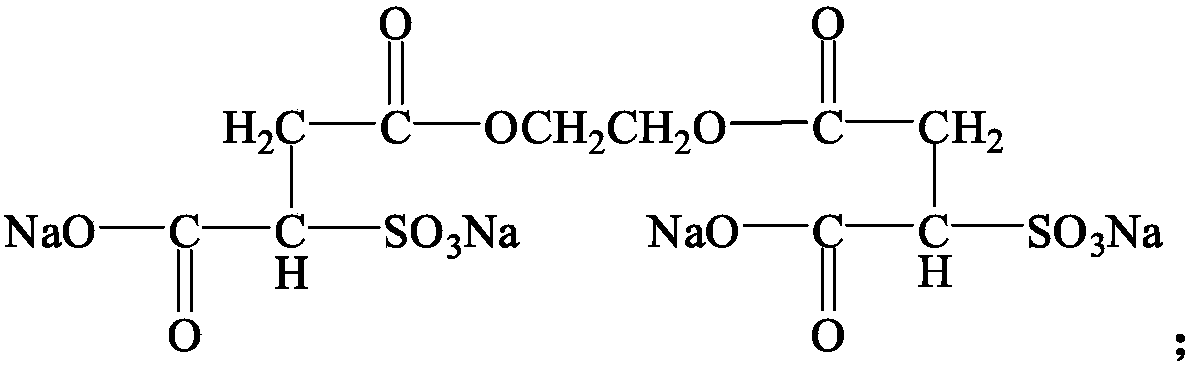

High-efficiency thick oil washing agent and preparation method thereof

A technology of washing oil and heavy oil, which is applied in the field of small molecule compounds, can solve the problems of difficult to peel off and disperse heavy oil, low polymer activity, low elution efficiency, etc., and achieve green environmental protection, high activity, and micelle concentration in the reaction process Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

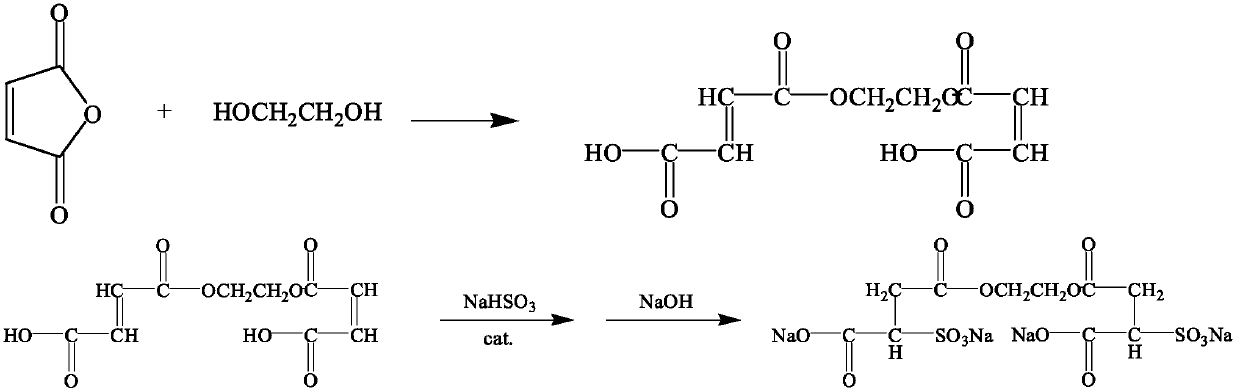

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: High-efficiency heavy oil detergent C 1 preparation of

[0023] (1) Add 1mol maleic anhydride, 49.03g ethylene glycol and 196.12g p-toluenesulfonic acid into a four-neck flask equipped with a stirrer, thermometer and reflux condensing device, then add 490.3g solvent acetone, and feed nitrogen for 3min , and then heated to 30°C, with a stirring rate of 200rpm; after complete dissolution, the temperature was raised to 60°C, and the stirring rate was adjusted to 500rpm, and the heating switch was turned off after 1 hour of reaction, and the mixture solution was obtained after cooling to room temperature;

[0024] (2) Install the water separator on the above-mentioned four-necked flask, and then configure 1.1mol sodium bisulfite into an aqueous solution with a mass concentration of 40% and add it to the four-necked flask, install a reflux device, heat to 105°C, and stir The speed is 400rpm, the power is turned off after 2 hours of reaction, and the mixture is...

Embodiment 2

[0029] Embodiment 2: High-efficiency heavy oil detergent C 2 preparation of

[0030] (1) Add 1mol maleic anhydride, 53.93g ethylene glycol and 392.24g p-toluenesulfonic acid into a four-neck flask equipped with a stirrer, thermometer and reflux condensing device, then add 784.49g solvent acetone, and feed nitrogen for 4min , and then heated to 50°C, with a stirring rate of 350rpm; after complete dissolution, the temperature was raised to 75°C, and the stirring rate was adjusted to 560rpm, and the heating switch was turned off after 4 hours of reaction, and the mixture solution was obtained after cooling to room temperature;

[0031] (2) Install the water separator on the above-mentioned four-necked flask, and then configure 1.16mol sodium bisulfite into an aqueous solution with a mass concentration of 40% and add it to the four-necked flask, install a reflux device, heat to 115°C, and stir The speed is 460rpm, the power is turned off after 8 hours of reaction, and the mixture...

Embodiment 3

[0035] Embodiment 3: High-efficiency heavy oil detergent C 3 preparation of

[0036] (1) Add 1mol maleic anhydride, 61.15g ethylene glycol and 415.6g p-toluenesulfonic acid into a four-neck flask equipped with a stirrer, thermometer and reflux condensing device, then add 856.3g solvent acetone, and feed nitrogen for 4min , and then heated to 40°C, with a stirring rate of 400rpm; after complete dissolution, the temperature was raised to 80°C, and the stirring rate was adjusted to 520rpm, and the heating switch was turned off after 3 hours of reaction, and the mixture solution was obtained after cooling to room temperature;

[0037] (2) Install the water separator on the above-mentioned four-necked flask, and then configure 1.2mol sodium bisulfite into an aqueous solution with a mass concentration of 40% and add it to the four-necked flask, install a reflux device, heat to 120°C, and stir The speed is 450rpm, the power is turned off after 5 hours of reaction, and the mixture is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com