Single crystal laser optical fiber based on surface microstructures as well as production method and application thereof

A microstructure and optical fiber technology, applied in microstructure optical fibers, glass optical fibers, clad optical fibers, etc., can solve the problems of reducing the transmission efficiency and service life of optical fibers, complicated preparation process routes, and thermal effects of optical fibers, so as to reduce the optical waveguide modulus. , avoid the complex process, the effect of high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

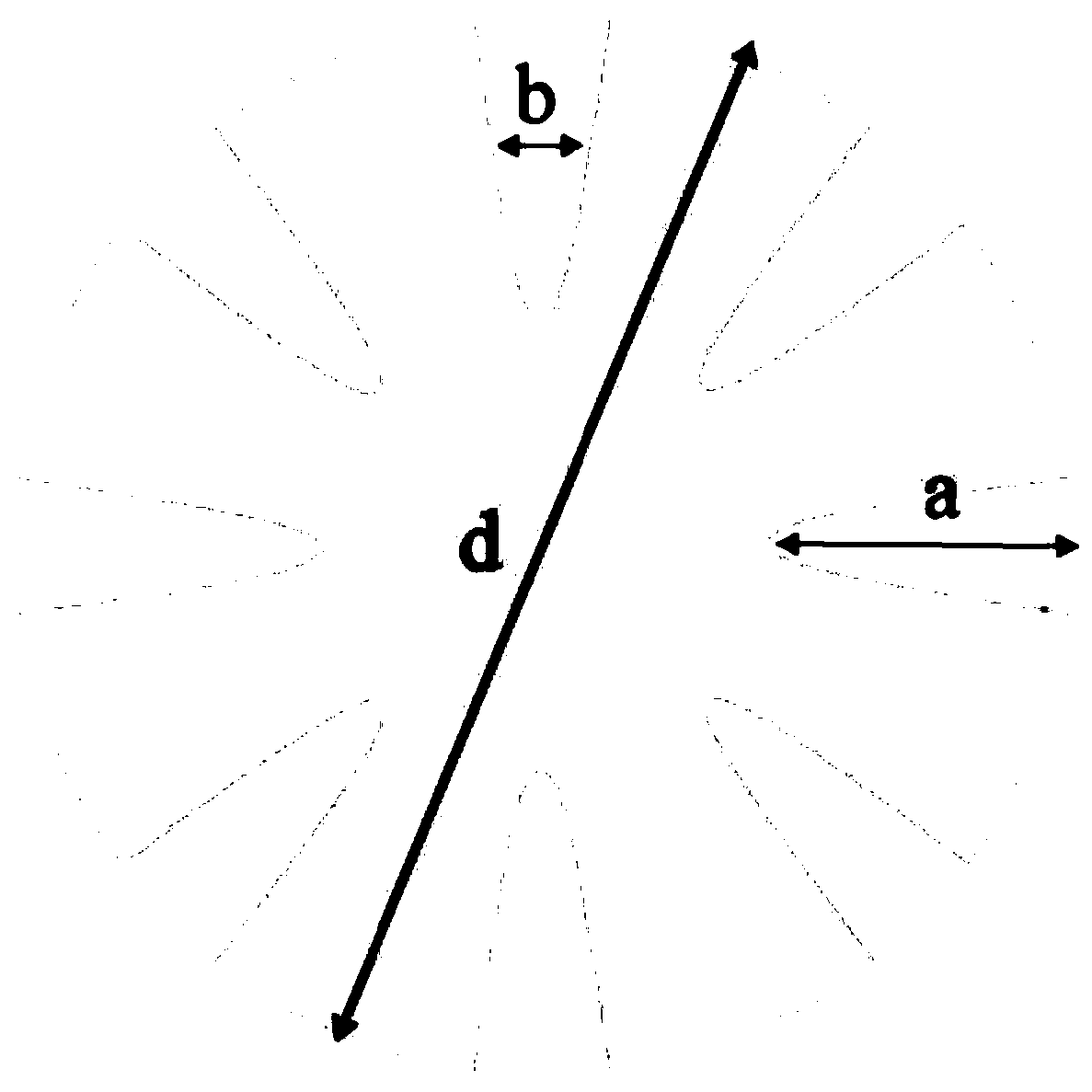

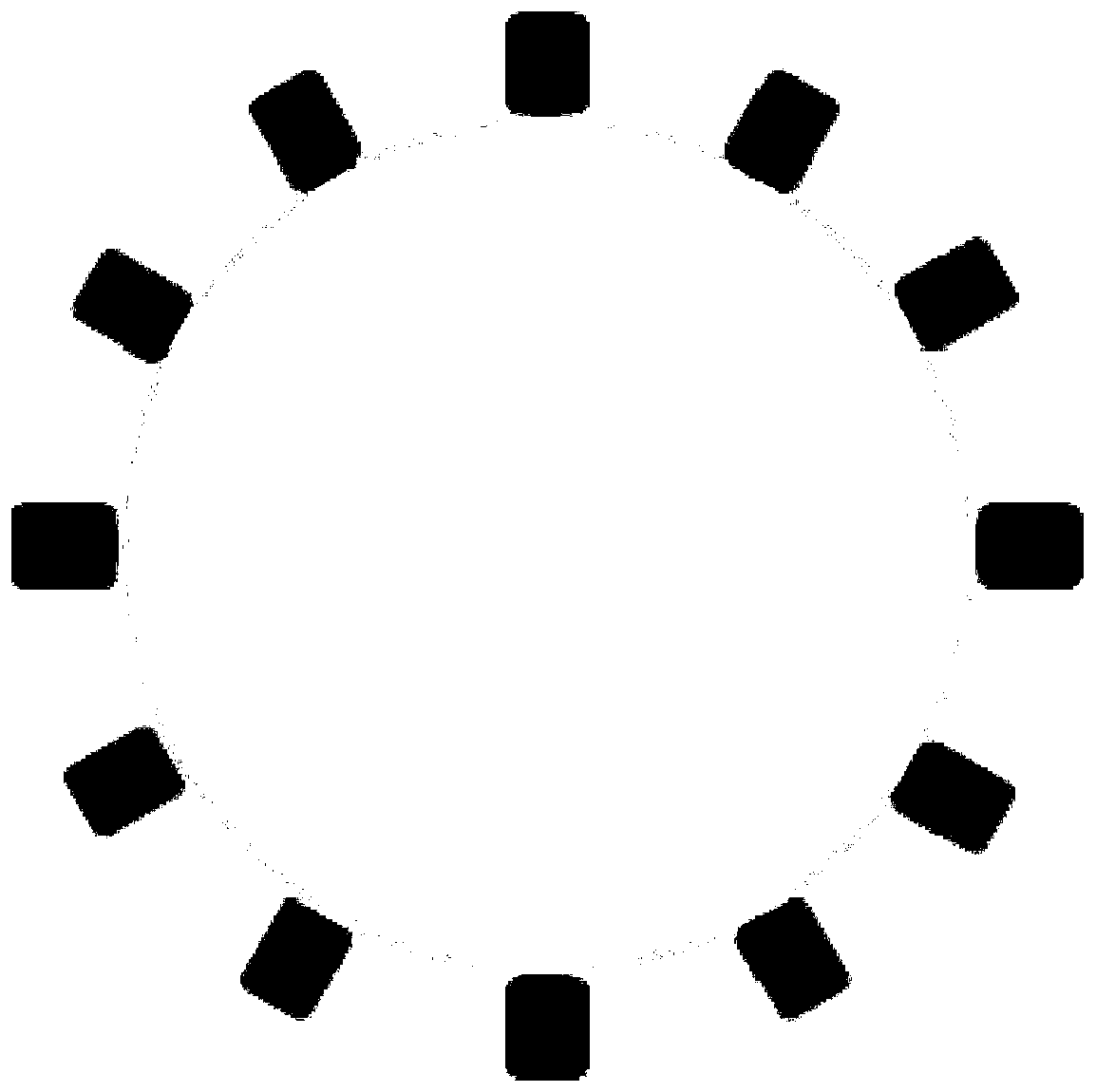

[0042] Such as figure 1 As shown, a femtosecond laser is used to perform microstructure processing on a sapphire single crystal fiber with a diameter of d=10μm and a length of 10cm, that is, a groove is uniformly cut on the surface of the single crystal fiber, and the shape of the groove end is parabolic. The depth a=1μm, the width of the paraboloid's midline is b=0.2μm; the groove spacing is equal, and the number of grooves processing around the core is 8.

Embodiment 2

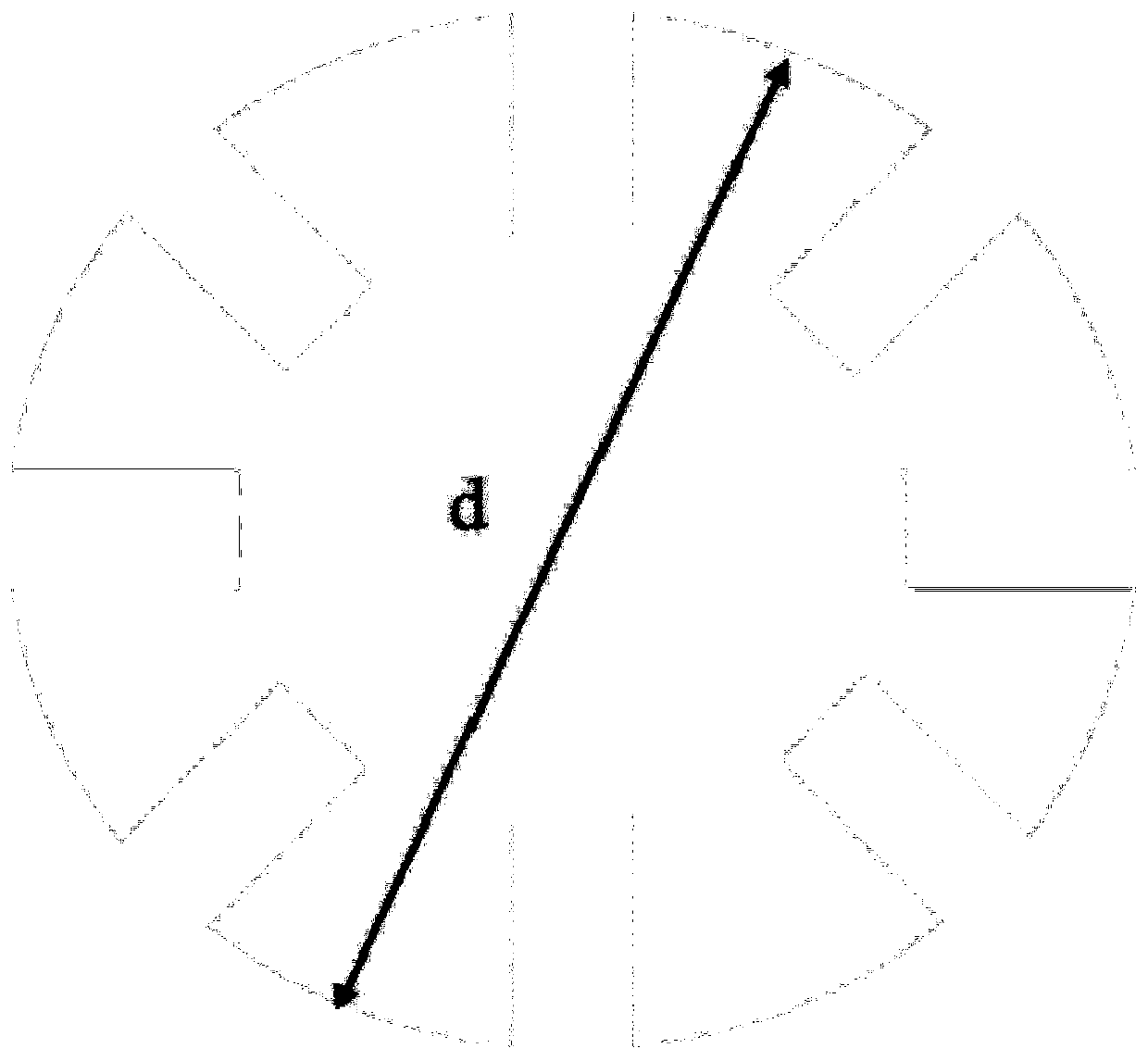

[0044] Such as figure 2 As shown, a femtosecond laser is used to perform microstructure processing on a sapphire single crystal fiber with a diameter of d=10μm and a length of 10cm. That is, grooves are uniformly cut on the surface of the single crystal fiber, and the shape of the groove end is rectangular, and the groove depth a=1μm, groove width b=0.2μm; groove spacing is equal, and the number of grooves processed around the core is 8.

Embodiment 3

[0046] As described in Example 2, the difference is that the groove processing width b=0.4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com