Plasma treatment method and plasma treatment device

A processing method and processing device technology, applied in the direction of measuring devices, optical devices, instruments, etc., to achieve good reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

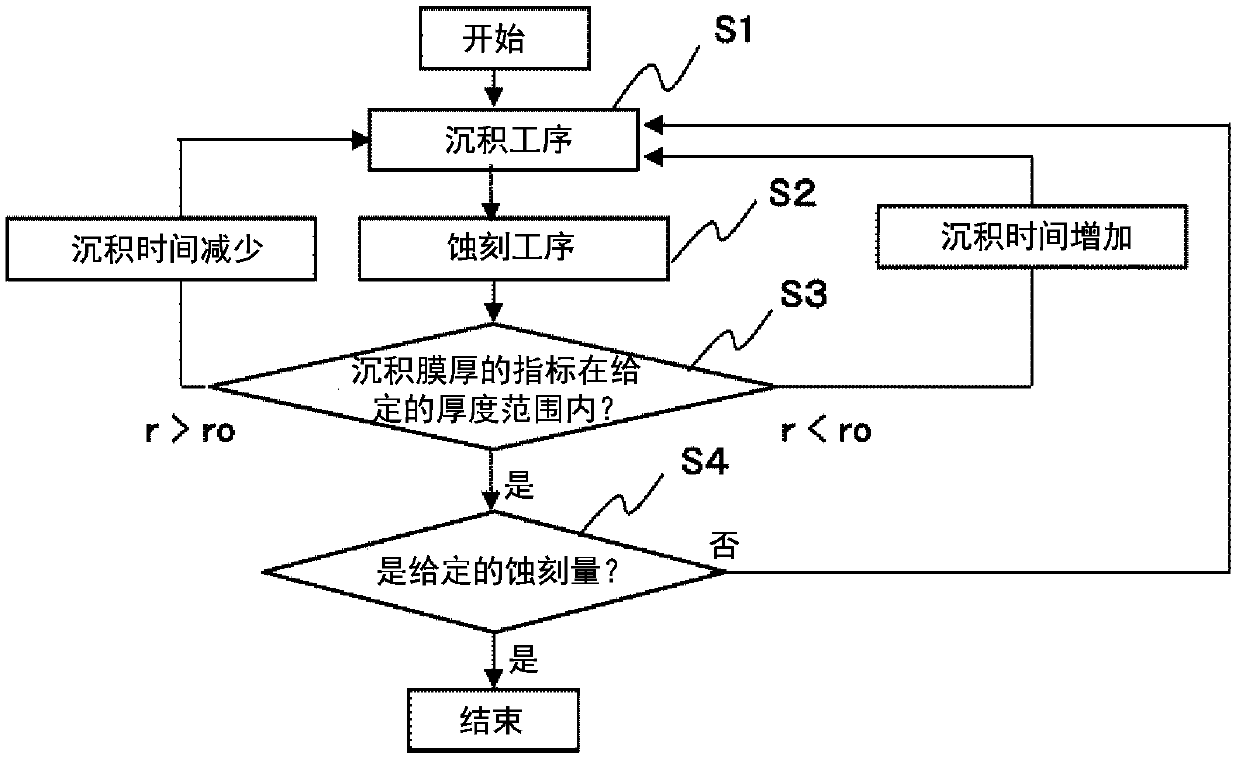

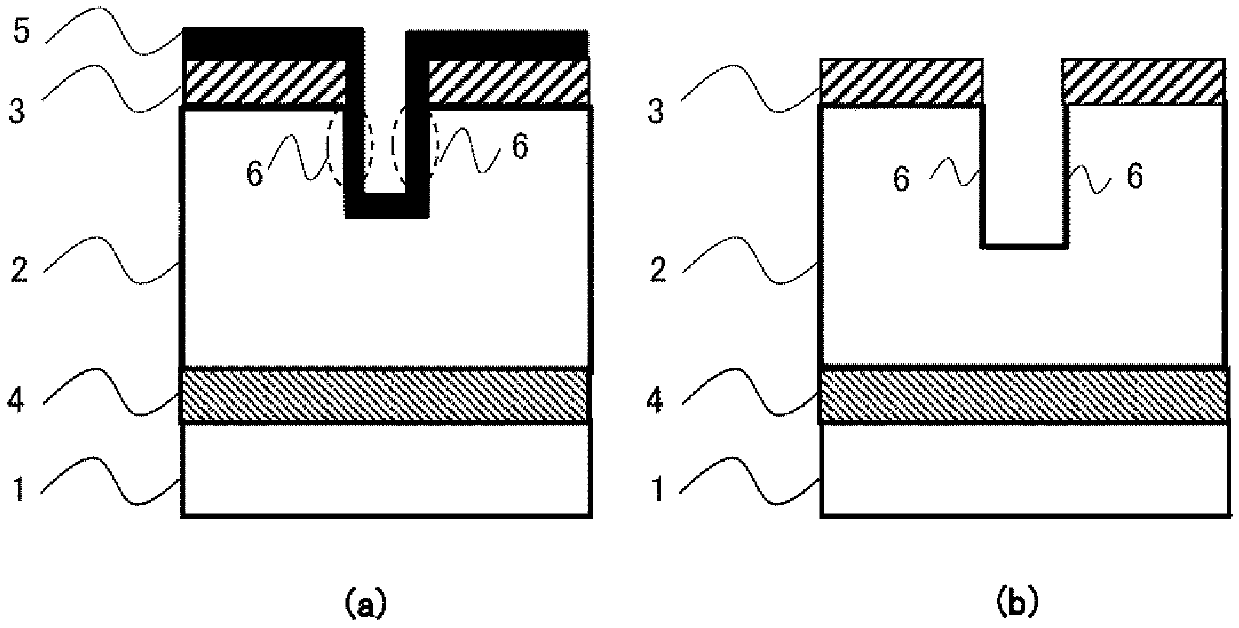

[0037] As Example 1, an example of a cyclic etching and etching apparatus that performs deposition steps and etching steps alternately to process fine patterns will be described. figure 1 It is a figure which shows an example of the process flow of the cyclic etching including several steps (S) concerning Example 1. figure 2 is for illustration figure 1 A schematic diagram of the process flow, figure 2 (a) is an explanatory diagram of a deposition process (S1), and (b) is an explanatory diagram of an etching process (S2). In this embodiment, as an example of the pattern to be etched, the following case is described: a non-etching layer 4 and an interlayer film of the material to be etched 2 are formed on the wafer 1 as the substrate to be etched, and the pattern to be etched is formed on the mask 3, i.e. A fine line and space pattern, in this case, etches the material 2 to be etched. In addition, in this embodiment, a case where etching is performed using energy of ions i...

Embodiment 2

[0070] Next, use Figure 11 A plasma processing apparatus comprising a cluster type etching tool (hereinafter referred to as a cluster tool) according to Example 2 will be described. Figure 11 It is a figure which shows one structure of the cluster tool of Example 2. As an example of this cluster tool, the case where the processing chamber of the etching apparatus is composed of three chambers is shown. The cluster tool includes a cassette loader 204 , a control PC 205 , a transport robot 207 , a control unit 220 , and a notch position adjustment table 221 in addition to three processing chambers. In the structure of this embodiment, the PC for control, the control part 220, and the three monitor control parts 36 can be collectively called the control part of a cluster tool.

[0071] In this cluster of tools, if the wafer cassette is placed on the wafer loader 204, the wafer 1 for processing is transported from the wafer cassette to the notch position matching process by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com