Coating slurry for frozen pre-fried foods, frozen pre-fried foods and preparation method of frozen pre-fried foods

A production method and pre-frying technology, which are applied in the directions of food ingredients as thickeners, food ingredients, and food coating, can solve problems such as healthy eating disorders, unfavorable diet health, increased fat content, etc., and reduce the oil absorption rate. , Widen the cooking method, maintain the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

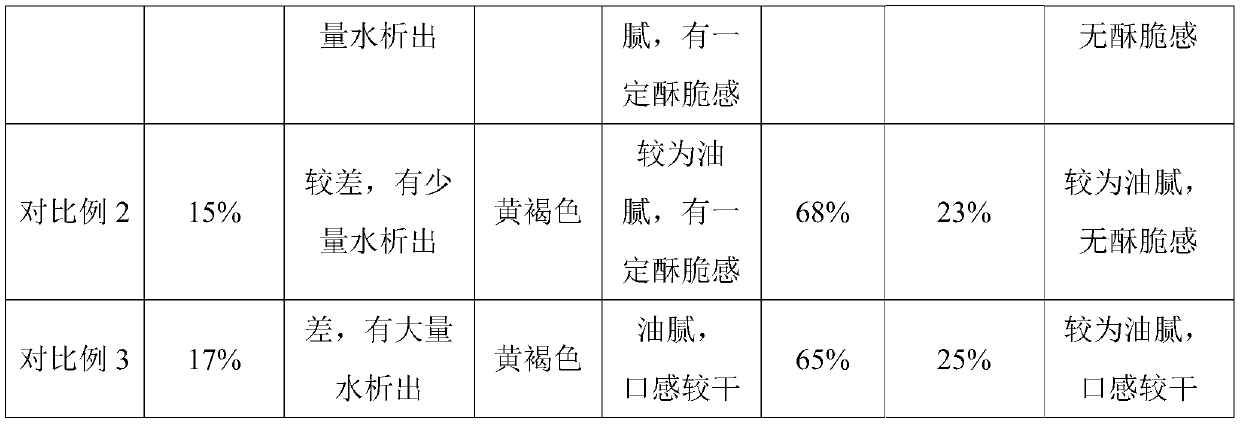

Examples

Embodiment 1

[0028] A kind of freezing pre-fried food, its preparation method comprises the following steps:

[0029] 1) Taking materials according to the following weight ratio, wherein each part by weight is calculated as 1g.

[0030] First, take the raw materials of the fish block core material in the following parts by weight: 1000 parts of tilapia meat, 350 parts of minced fish, 300 parts of water, 30 parts of ginger juice, 45 parts of phosphate starch, 12 parts of egg white powder, 27 parts of salt, white sugar 38 parts, 5 parts of disodium dihydrogen pyrophosphate, 3 parts of disodium hydrogen phosphate, 5 parts of konjac gum, 1 part of guar gum, 60 parts of sea bath sugar, 30 parts of sorbitol, 15 parts of white pepper powder.

[0031] Take the starch as a pre-coating flour.

[0032]The raw materials of the coating material are taken in the following parts by weight: 400 parts of starch, 300 parts of wheat flour, 100 parts of modified fish muscle fiber protein, 15 parts of salt, 2...

Embodiment 2

[0044] A kind of freezing pre-fried food, its preparation method comprises the following steps:

[0045] 1) Taking materials according to the following weight ratio, wherein each part by weight is calculated as 1g.

[0046] First, take the raw materials of fish block core material in the following parts by weight: 900 parts of tilapia meat, 300 parts of minced fish, 250 parts of water, 25 parts of ginger juice, 50 parts of phosphate starch, 10 parts of egg white powder, 20 parts of salt, white sugar 30 parts, 4 parts of disodium dihydrogen pyrophosphate, 5 parts of disodium hydrogen phosphate, 3 parts of konjac gum, 3 parts of guar gum, 50 parts of sea bath sugar, 40 parts of sorbitol, 10 parts of white pepper powder.

[0047] Take the starch as a pre-coating flour.

[0048] Get the raw materials of the coating material in the following parts by weight: 450 parts of starch, 250 parts of wheat flour, 80 parts of modified fish muscle fiber protein, 10 parts of salt, 15 parts of...

Embodiment 3

[0060] A kind of freezing pre-fried food, its preparation method comprises the following steps:

[0061] 1) Taking materials according to the following weight ratio, wherein each part by weight is calculated as 2g.

[0062] First, take the raw materials of the fish block core material in the following parts by weight: 1100 parts of tilapia meat, 500 parts of minced fish, 350 parts of water, 20 parts of ginger juice, 60 parts of phosphate starch, 15 parts of egg white powder, 30 parts of salt, white sugar 50 parts, 7 parts of disodium dihydrogen pyrophosphate, 6 parts of disodium hydrogen phosphate, 6 parts of konjac gum, 2 parts of guar gum, 70 parts of sea bath sugar, 50 parts of sorbitol, 20 parts of white pepper powder.

[0063] Take the starch as a pre-coating flour.

[0064] Get the raw materials of the coating material in the following parts by weight: 300 parts of starch, 350 parts of wheat flour, 120 parts of modified fish muscle fiber protein, 20 parts of salt, 25 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com