Preparation method for black phosphorus-activated graphene heterojunction loaded nickel nitride particles

A graphene and heterojunction technology, applied in the field of materials science, can solve the problems of high overpotential, limited hydrogen production efficiency, slow kinetics, etc., achieve the effect of simple preparation method, easy to obtain raw materials, and improve hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

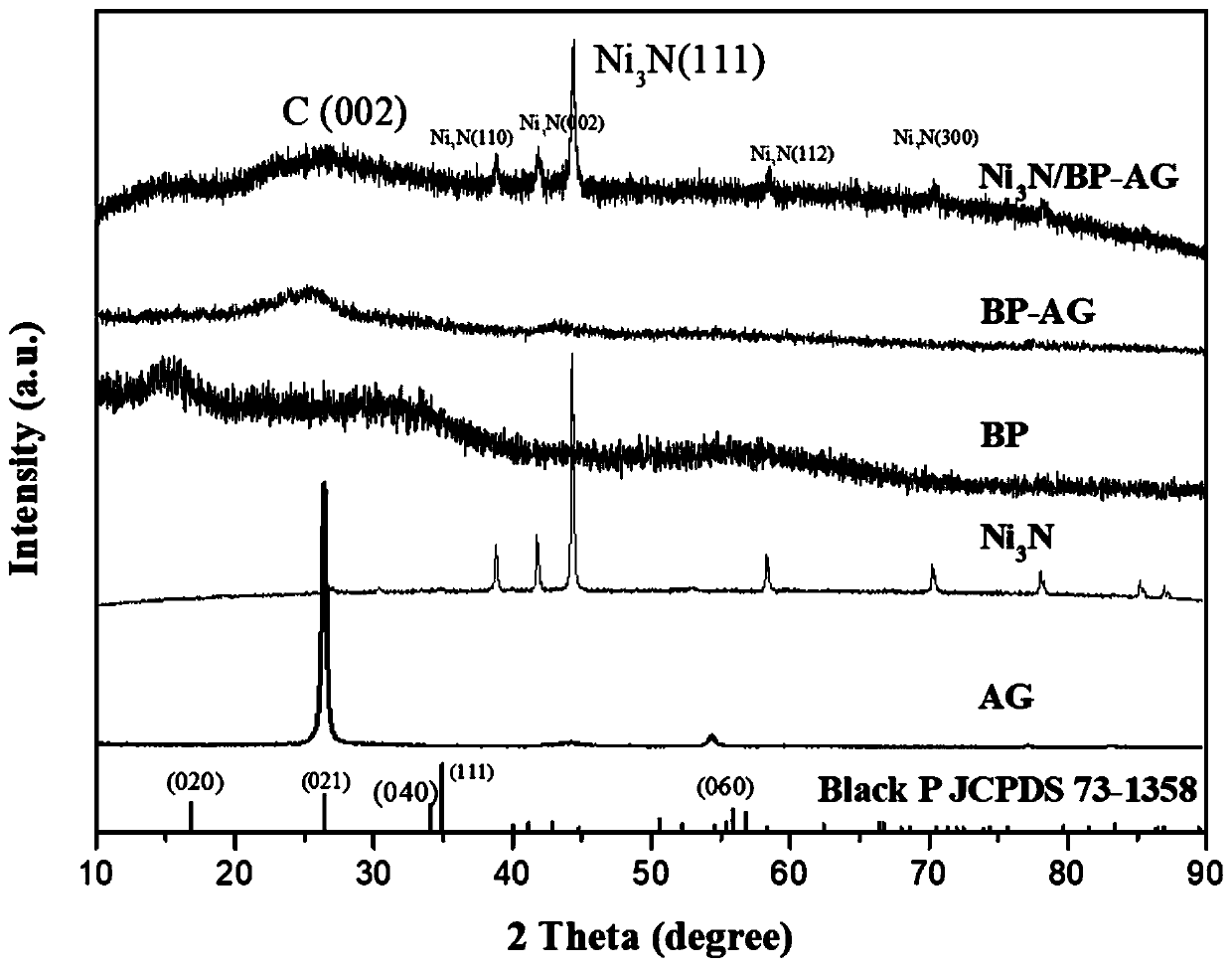

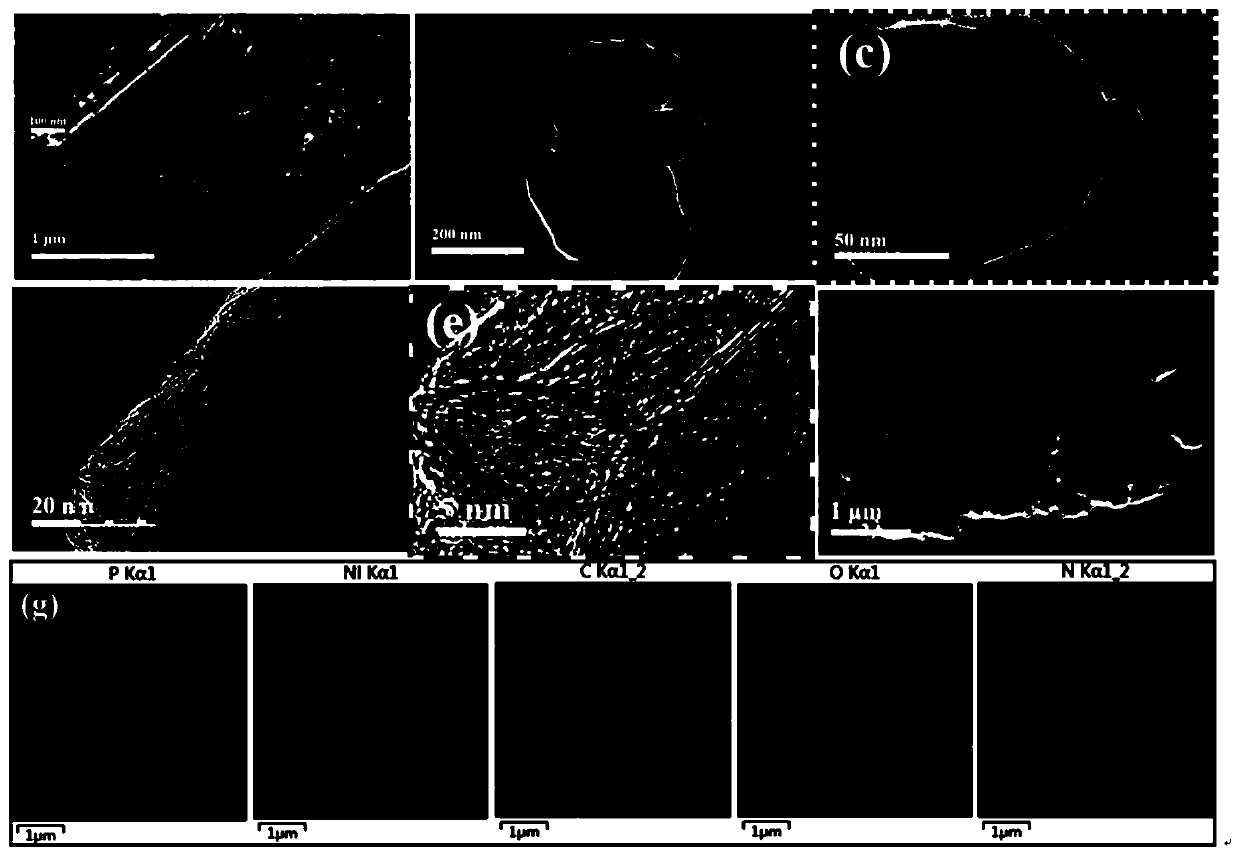

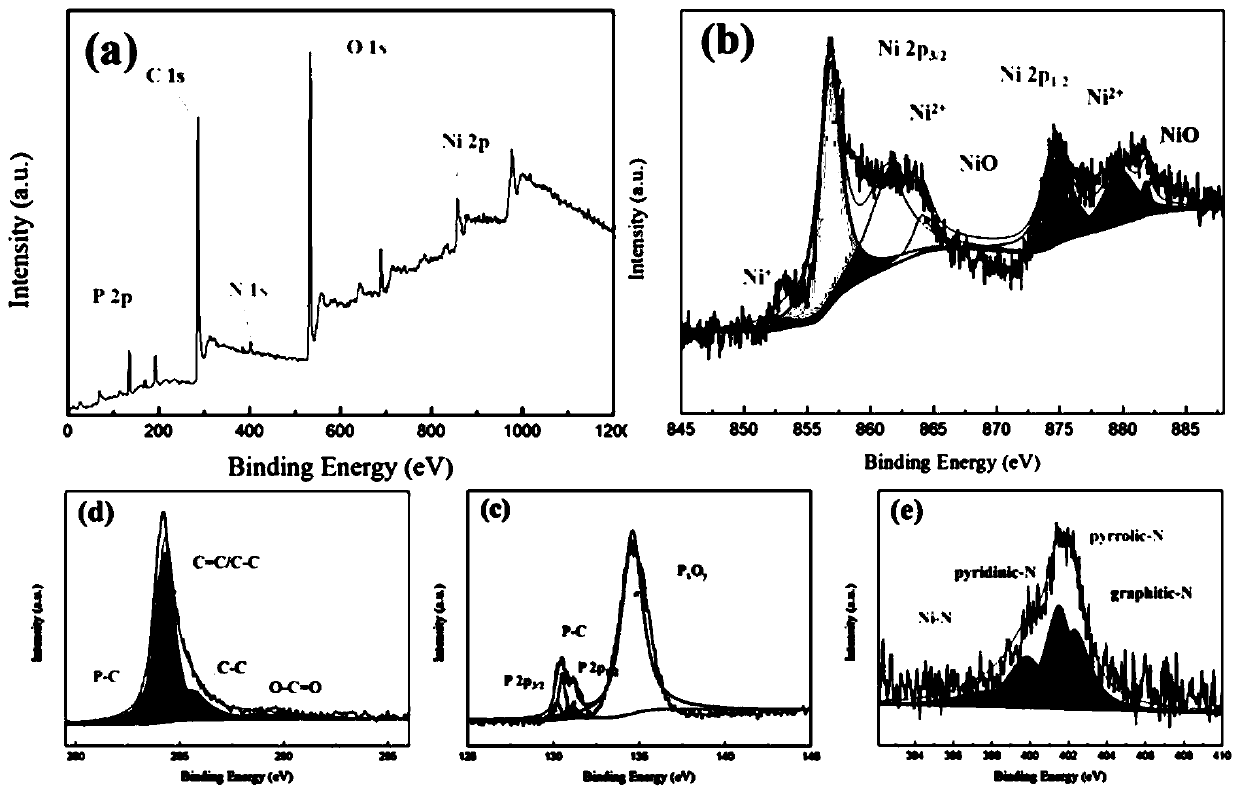

[0024] A method for preparing black phosphorus-activated graphene heterojunction loaded nickel nitride particles, the specific steps are:

[0025] (1) Preparation of black phosphorus-activated graphene heterojunction materials:

[0026] Preparation of black phosphorus: Add 4 g of red phosphorus (red phosphorus) and 60 mL of deionized water into a 100 mL hydrothermal kettle at room temperature, and conduct a hydrothermal reaction at 180°C for 15 hours to remove the oxide layer on the surface of red phosphorus. After taking it out and drying it, grind it with an agate mortar for 1 hour to obtain a black phosphorus precursor, then put the precursor in a stainless steel ball mill tank, fill it with argon gas at normal temperature and pressure for 0.5 hours, ensure that the ball mill tank is in an argon environment, and then ball mill After the tank is sealed, perform mechanical ball milling for 50 hours at a speed of 500 r / min. After the mechanical ball milling is completed, the ...

Embodiment 2

[0039] Adopt a method similar to Example 1 to prepare black phosphorus-activated graphene heterojunction loaded nickel nitride particles, the difference is that the mass ratio of the black phosphorus nanosheet material to the graphene nanosheet material is 1:0.5 , the mass ratio of black phosphorus-activated graphene heterojunction material to nickel nitride particles is 1:0.33.

Embodiment 3

[0041] Adopt a method similar to Example 1 to prepare black phosphorus-activated graphene heterojunction loaded nickel nitride particles, the difference is that the mass ratio of the black phosphorus nanosheet material to the graphene nanosheet material is 1:2 , the mass ratio of black phosphorus-activated graphene heterojunction material to nickel nitride particles is 1:0.67.

[0042] Figure 5 It is the linear sweep voltammogram and the corresponding Tafel slope diagram of black phosphorus-activated graphene heterojunction loaded nickel nitride particles in 1M KOH solution of Examples 1-3.

[0043] Wherein, the black phosphorus-activated graphene heterojunction supported nickel nitride particles (Ni 3 N / BP-AG 1), at up to 10mA cm -2 The overpotential is 233mV at the current density, and the Tafel slope is 42mV dec -1 , while the black phosphorus-activated graphene heterojunction supported nickel nitride particles (Ni 3 N / BP-AG 2), the overpotential is 308mV, and the Tafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com