Hollow core energy transfer mid-infrared fiber and preparation method thereof

An infrared light, hollow core technology, applied in the direction of multi-layer core/cladding fiber, cladding fiber, glass manufacturing equipment, etc. Achieve tunability, reduce losses, and improve tolerance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

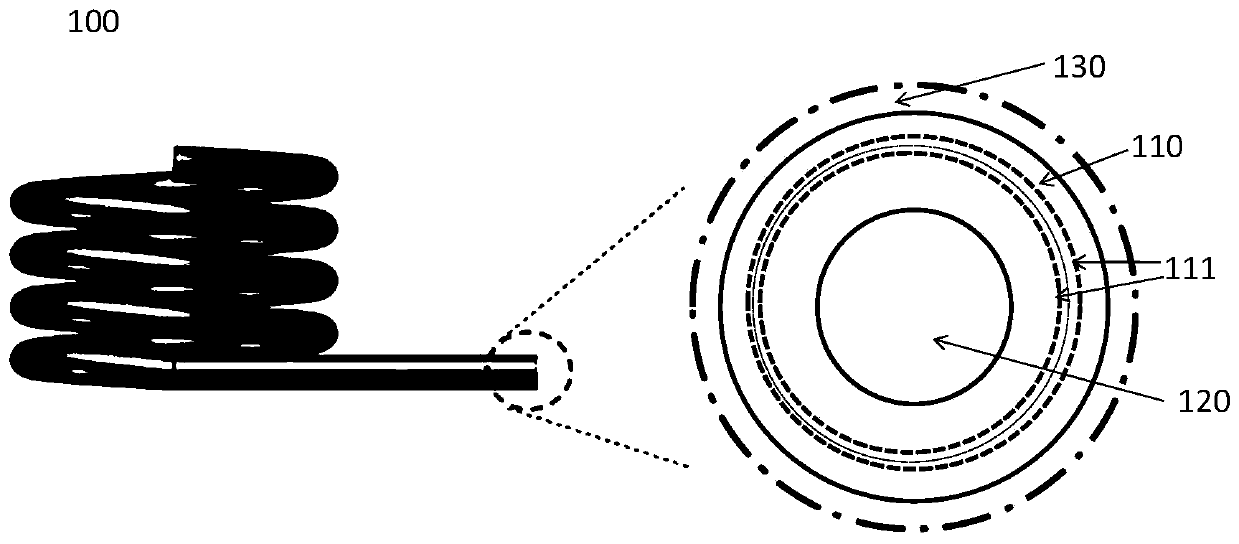

[0042] A hollow-core energy transmission mid-infrared optical fiber 100, which is applied to the laser transmission of quantum cascade lasers, such as figure 1 As shown, it is in the shape of a hollow tube, including: an optical fiber cladding 110 and an air core 120 inside, and an optical fiber polymer protective layer 130 arranged on the outer surface of the optical fiber cladding; wherein, the optical fiber cladding includes alternately spaced The chalcogenide glass layer and the polymer layer, the material of the chalcogenide glass layer includes tellurium element.

[0043] It should be noted, figure 1 , the outermost dotted coil and its adjacent solid coil represent the fiber polymer protective layer 130, the area defined between the two solid coils is the fiber cladding 110, and the innermost solid coil delineates the The area is the air core 120 .

[0044] The materials of chalcogenide glass layer and polymer layer can be selected in a wide range. Any polymer material w...

Embodiment 2

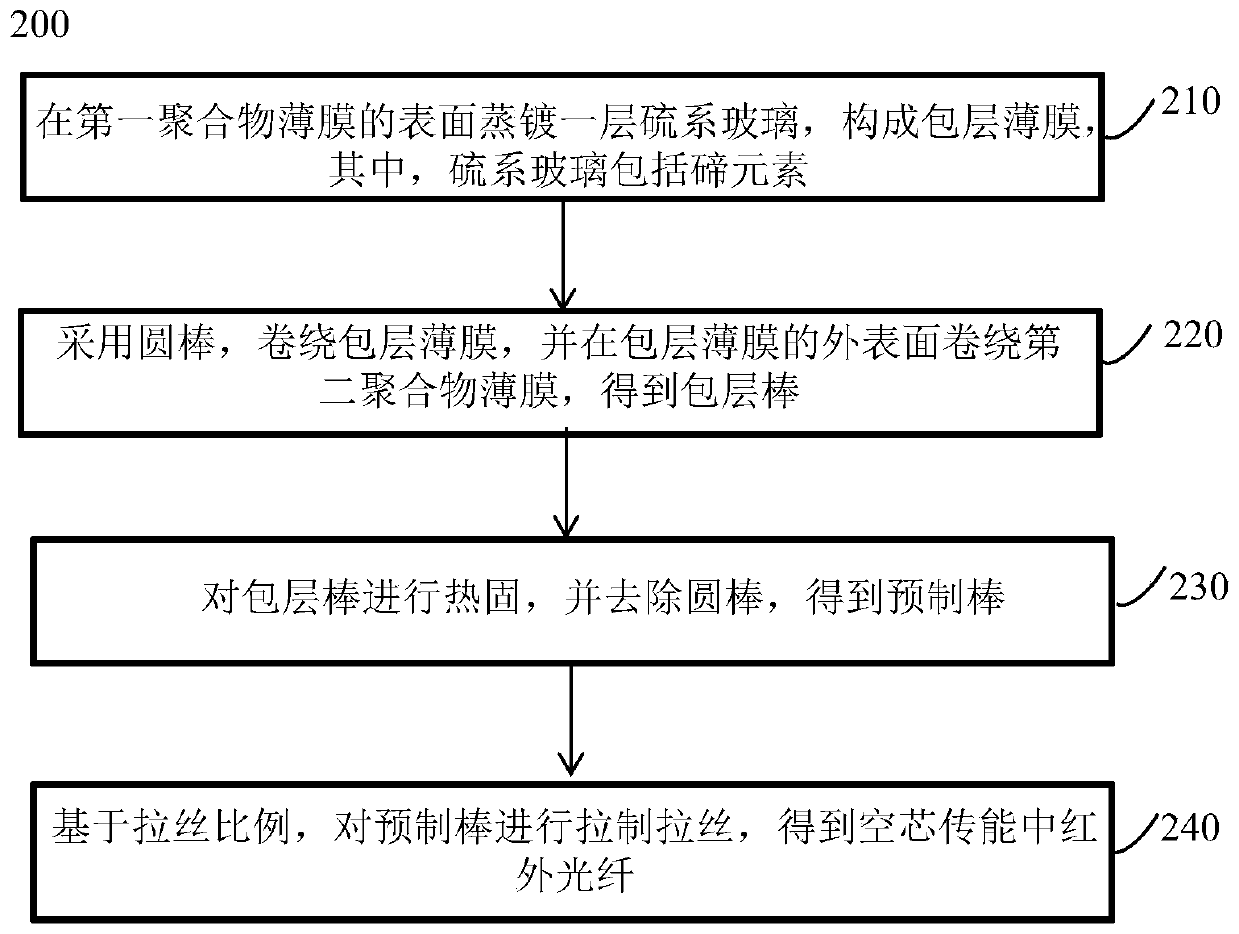

[0061] A method 200 for preparing a mid-infrared optical fiber for energy transmission with a hollow core according to Embodiment 1, comprising:

[0062] Step 210, evaporating a chalcogenide glass layer on the surface of the first polymer film to form a cladding film, wherein the chalcogenide glass includes tellurium element;

[0063] Step 220, using a round rod, winding the clad film, and winding a second polymer film on the outer surface of the clad film to obtain a clad rod;

[0064] Step 230, heat-setting the clad rod, and removing the round rod to obtain a prefabricated rod;

[0065] Step 240 , based on the drawing ratio, drawing and drawing the preform rod to obtain a hollow-core energy-transmitting mid-infrared optical fiber.

[0066] By adopting the method, the above-mentioned periodic structure can be realized simply and conveniently, wherein the chalcogenide glass layer is coated on the surface of the polymer film by vapor deposition, which ensures the uniformity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com