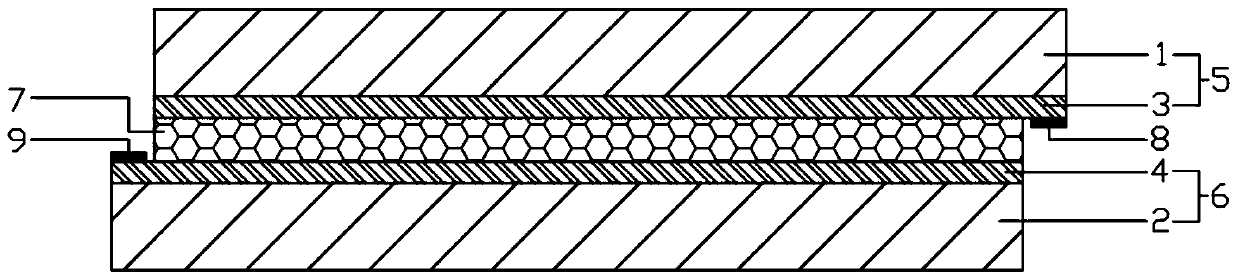

Polymer dispersed liquid crystal film based on polymer transparent conductive substrate and manufacturing method thereof

A technology of polymer transparent and conductive substrates, applied in optics, instruments, nonlinear optics, etc., can solve the problems of pushing up the market price of polymer dispersed liquid crystal films, high investment and operating costs, and restricting application fields. Improve off-state shielding, increase the upper limit operating temperature, and broaden the effect of application fields and scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step A: Add 20g of isopropanol to 1wt% PEDOT:PSS aqueous solution (the weight ratio of PEDOT and PSS is 1:2.5), mechanically stir for 40min at room temperature, and mix evenly to obtain a PEDOT solution. The above PEDOT solution is scraped Coated on a polyethylene terephthalate (PET) substrate (thickness 188 μm) with a size of 21cm*30cm, and coated two sheets in total, and controlled the wet film thickness to 300nm, and put the above two coated films into an oven Curing at 130°C for 30 minutes to obtain PEDOT conductive film, which is recorded as 1-A1 and 1-A2. Test the parameters of PEDOT conductive film: square resistance 80 ohms, full-line transmittance 86.5%, haze 0.27%;

[0052] Step B: In an environment protected from light or yellow light, 26% (mass percentage, the same below) of polyurethane acrylate (viscosity range 3000-4000cps / 25°C), 30% of isobornyl acrylate, 30% of hydroxybutyl acrylate, formazan 8% hydroxyethyl acrylate, 5% ethoxyethoxyethyl acrylate, and ...

Embodiment 2

[0058] Step A: The manufacturing method of the PEDOT conductive film is the same as step A in Example 1, wherein the selected base material is changed to a PET film with a size of 21cm*30cm and a thickness of 100 μm, and two pieces are made, which are recorded as 2-A1, 2 -A2, test the parameters of PEDOT conductive film: square resistance 81 ohms, full-line transmittance 85.8%, haze 0.25%;

[0059] Step B: In a dark or yellow light environment, mix 20% (mass percentage, the same below) of polyurethane acrylate (viscosity range 2000-3000cps / 25°C), epoxy acrylate 6% (viscosity range 6000-8000cps / 25°C) ), trimethylolpropane triacrylate 30%, 1,6-hexanediol diacrylate 30%, hydroxyethyl methacrylate 8%, acryloylmorpholine 5%, 2,4,6-trimethyl Benzoyl-diphenylphosphorous oxide 1% was mixed in proportion, mechanically stirred for 40min, then transferred to a vacuum defoaming device, and continued to defoam for 60min. It is 2-B, the test viscosity is 380cps / 25℃;

[0060] Step C: Mix 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com