Synthesis method of calcium cyanamide

A technology of calcium cyanamide and a synthesis method, applied in directions such as cyanamide, can solve the problems of high energy consumption, high production cost, large pollution, etc., and achieve the effects of low energy consumption, short production cycle, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

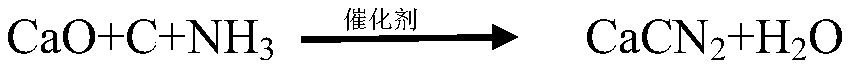

[0029] Using calcium oxide, carbon powder and ammonia as raw materials, under the action of calcium fluoride, the target product calcium cyanamide is synthesized. The reaction equation is as follows:

[0030]

[0031] The specific steps are as follows:

[0032] (1 calcium oxide 50.18g, carbon powder 11.78g and calcium fluoride 3.5g are added in the reactor;

[0033] (2) Introduce ammonia gas at 10 L / min, wait for ammonia gas to be introduced for 2 minutes, then heat up to 300°C, and react for 50 hours;

[0034] (3) drop to 25 ℃ after completion of the reaction, the solid obtained is 66.40 g, the yield of calcium cyanamide is 82.16%, and the purity is 88.7%.

Embodiment 2

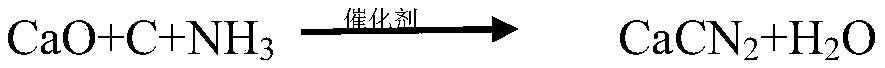

[0036] Using calcium oxide, carbon powder and ammonia as raw materials, under the action of calcium chloride, the target product calcium cyanamide is synthesized. The reaction equation is as follows:

[0037]

[0038] The specific steps are as follows:

[0039] (1) Add 50.18g of calcium oxide, 16.13g of carbon powder and 19.89g of calcium chloride into the reactor;

[0040] (2) Feed ammonia gas at 500 L / min, wait for 1 minute to feed ammonia gas, then heat up to 1000°C, and react for 5 hours;

[0041] (3) drop to 25 ℃ after completion of the reaction, the solid product obtained is 72.68g, the yield of calcium cyanamide is 90.84%, and the purity is 89.6%.

Embodiment 3

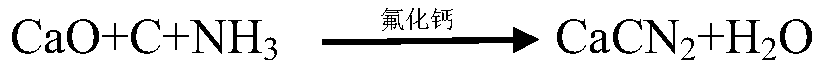

[0043] Using calcium oxide, carbon powder and ammonia as raw materials, the target product calcium cyanamide is synthesized under the action of zinc oxide. The reaction equation is as follows:

[0044]

[0045] The specific steps are as follows:

[0046] (1) Add 50.18g of calcium oxide, 13.98g of carbon powder and 7.29g of zinc oxide into the reactor;

[0047] (2) Feed ammonia gas at 200L / min, wait for 1 minute to feed ammonia gas, then heat up to 750°C, and react for 30 hours;

[0048] (3) After the reaction was completed, the temperature was lowered to 25° C. to obtain 71.02 g of solid product, the yield of calcium cyanamide was 93.35%, and the purity was 93.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com