Membrane aerated biofilm micro-aerobic sludge bed process and wastewater treatment method thereof

A membrane aeration biofilm and sludge bed technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem of complex sludge treatment process, large infrastructure investment, high energy Consumption and other issues, to achieve the effect of improving oxygen mass transfer efficiency, low operating energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The effective membrane area per unit volume of the biofilm aeration component 5 is controlled at 0.001-1㎡ / L.

[0019] The biofilm aeration assembly 5 is completely submerged in the sludge layer at the bottom of the reactor. The biofilm aeration component is produced by Hangzhou Haotian Membrane Technology Co., Ltd., and the product name is polypropylene hydrophobic hollow fiber membrane.

[0020] The sludge volume accounts for 1-100% of the total volume of the biofilm microaerobic sludge bed 1 .

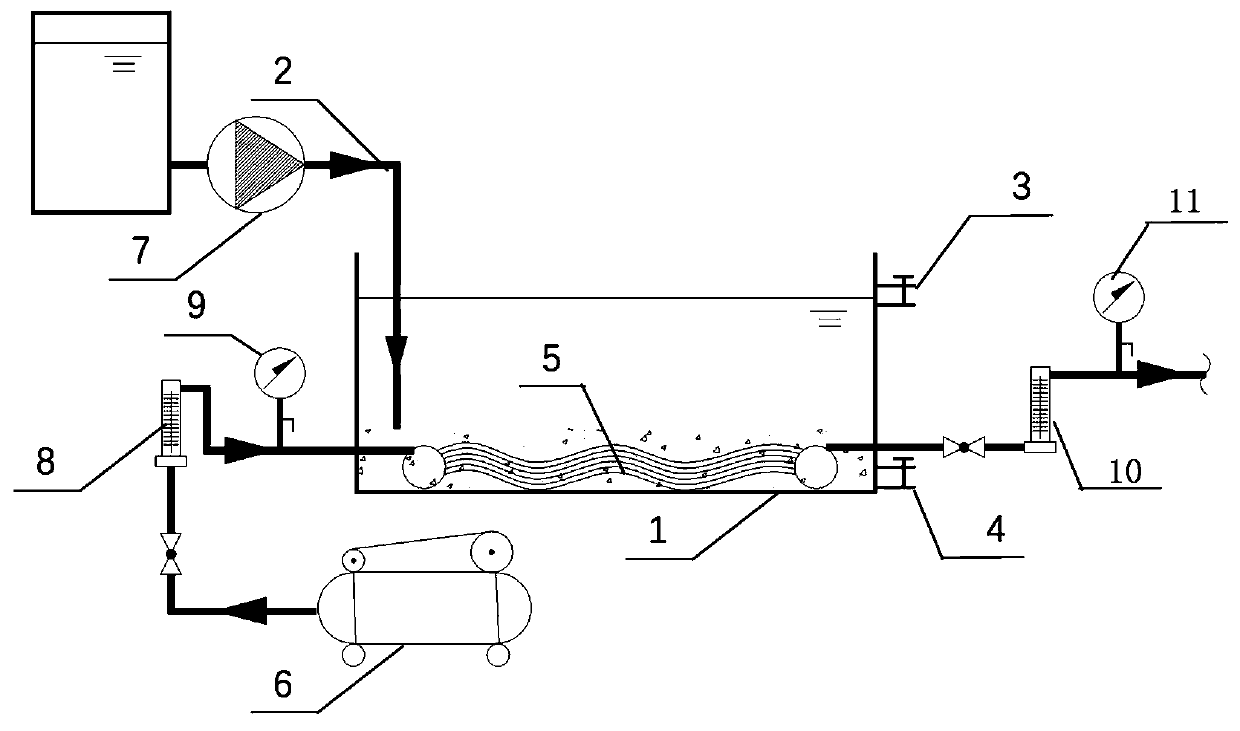

[0021] The membrane aeration biofilm micro-oxygen sludge bed process of the present invention is realized by adopting the following technical scheme: the film aeration biofilm micro-oxygen sludge bed process comprises a biofilm micro-oxygen sludge bed, a sludge bed inlet pipe, Sludge bed outlet pipe, sludge discharge pipe, biofilm aeration component, air pump, circulation pump / peristaltic pump, first air flow meter, first pressure gauge, second air flow meter, second pressure...

Embodiment 1

[0028] Example 1: Combining figure 1 Illustrate present embodiment, present embodiment utilizes the concrete method of processing low C / N ratio waste water described in specific embodiment as follows:

[0029] The waste water enters from the bottom of the biofilm microaerobic sludge bed 1 through the sludge bed inlet pipe 2 through the peristaltic pump, and the pollutants in the waste water are treated by the microorganisms attached to the outside of the biofilm aeration module 5 and the sludge bed flora, and the biological Membrane aeration module 5 provides the oxygen required for the process, and the first air flowmeter 8 and the first pressure gauge 9 on the sludge bed inlet pipe 2 and the sludge bed outlet pipe 3, as well as the second air flowmeter 10 and the first pressure gauge Table 11 Control the amount of oxygen, and control the dissolved oxygen concentration to 0.3mg / L~0.5mg / L; after the wastewater is treated, it is overflowed and discharged from the sludge bed out...

Embodiment 2

[0033] Embodiment 2: Combination figure 1 Illustrate present embodiment, present embodiment utilizes the concrete method of processing general C / N ratio waste water described in specific embodiment as follows:

[0034]The waste water enters from the bottom of the biofilm microaerobic sludge bed 1 through the sludge bed inlet pipe 2 through the peristaltic pump, and the pollutants in the waste water are treated by the microorganisms attached to the outside of the biofilm aeration module 5 and the sludge bed flora, and the biological Membrane aeration module 5 provides the oxygen required for the process, and the first air flowmeter 8 and the first pressure gauge 9 on the sludge bed inlet pipe 2 and the sludge bed outlet pipe 3, as well as the second air flowmeter 10 and the first pressure gauge Table 11 Control the amount of oxygen, and control the concentration of dissolved oxygen to 0.6mg / L~0.9mg / L; after the wastewater is treated, it is discharged from the overflow of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com