Technology for treating landfill leachate by non-biochemical process

A landfill leachate, non-biochemical technology, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of large investment, poor control ability, and difficulty in reaching the standard, so as to improve the reaction efficiency , The effect of improving the oxidation function and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

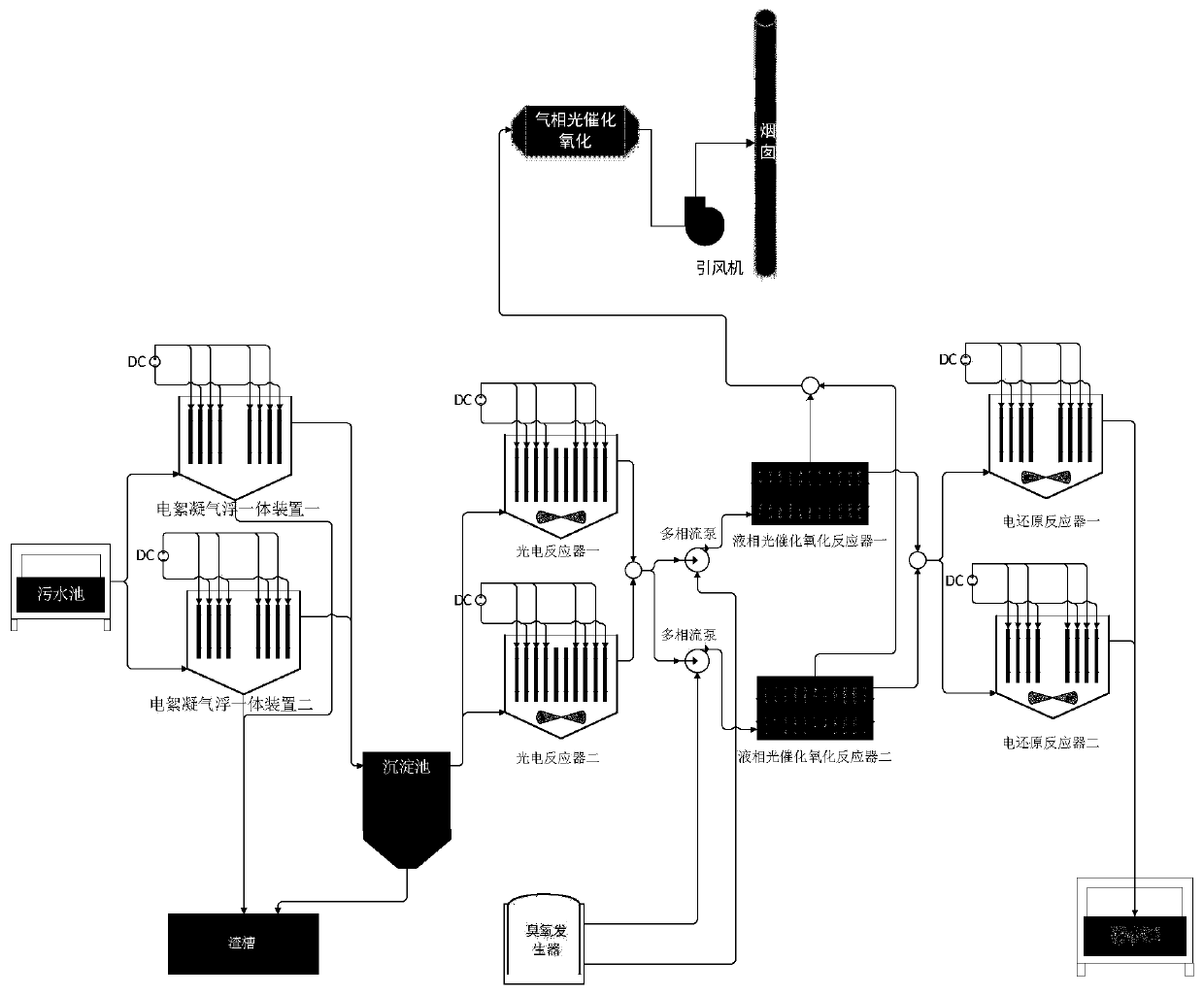

[0118] Such as figure 1 A kind of non-biochemical method treatment landfill landfill leachate technique shown, described technique comprises the steps:

[0119] Step S1: leachate electrocoagulation air flotation sedimentation treatment;

[0120] Step S2: the leachate treated in step S1 is treated by photolysis and electrochemical reaction;

[0121] Step S3: The leachate treated in step S2 is treated by an electric field cooperative photocatalytic oxidation reaction. After the test reaches the standard, the non-biochemical treatment of the leachate is completed. If the test does not meet the standard, enter step S4: the leachate treated in step S3 After the electrochemical reduction reaction treatment, the non-biochemical treatment of the leachate is completed.

[0122] Specifically, step S2 is based on a photolysis cooperative electrochemical treatment device, the device includes a device body, which is provided with a plurality of anodes, a plurality of cathodes and a refer...

Embodiment 2

[0144] A non-biochemical process for treating landfill landfill leachate is characterized in that the process comprises the following steps:

[0145] Step S1: leachate electrocoagulation air flotation sedimentation treatment;

[0146] Step S2: the leachate treated in step S1 is treated by photolysis and electrochemical reaction;

[0147] Step S3: The leachate treated in step S2 is treated by an electric field cooperative photocatalytic oxidation reaction. After the detection reaches the standard, the non-biochemical treatment of the leachate is completed. If the detection does not meet the standard, enter step S4: the leachate treated in step S3 After the electrochemical reduction reaction treatment, the non-biochemical treatment of the leachate is completed.

[0148] Specifically, step S2 is based on a photolysis cooperative electrochemical treatment device, the device includes a device body, which is provided with a plurality of anodes, a plurality of cathodes and a referen...

Embodiment 3

[0170] A non-biochemical process for treating landfill landfill leachate is characterized in that the process comprises the following steps:

[0171] Step S1: leachate electrocoagulation air flotation sedimentation treatment;

[0172] Step S2: the leachate treated in step S1 is treated by photolysis and electrochemical reaction;

[0173] Step S3: The leachate treated in step S2 is treated by an electric field cooperative photocatalytic oxidation reaction. After the test reaches the standard, the non-biochemical treatment of the leachate is completed. If the test does not meet the standard, enter step S4: the leachate treated in step S3 After the electrochemical reduction reaction treatment, the non-biochemical treatment of the leachate is completed.

[0174] Specifically, step S2 is based on a photolysis cooperative electrochemical treatment device, the device includes a device body, which is provided with a plurality of anodes, a plurality of cathodes and a reference electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com