Low-loss and low-thermal-expansion magnesium-aluminum-silicon-based glass-ceramic material and preparation method thereof

A low thermal expansion, glass-ceramic technology, applied in the field of electronic ceramic materials, can solve the problems of mismatched thermal expansion coefficient, large signal transmission delay, poor matching of silicon chips, etc., to achieve high density, increase signal transmission speed, reduce The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

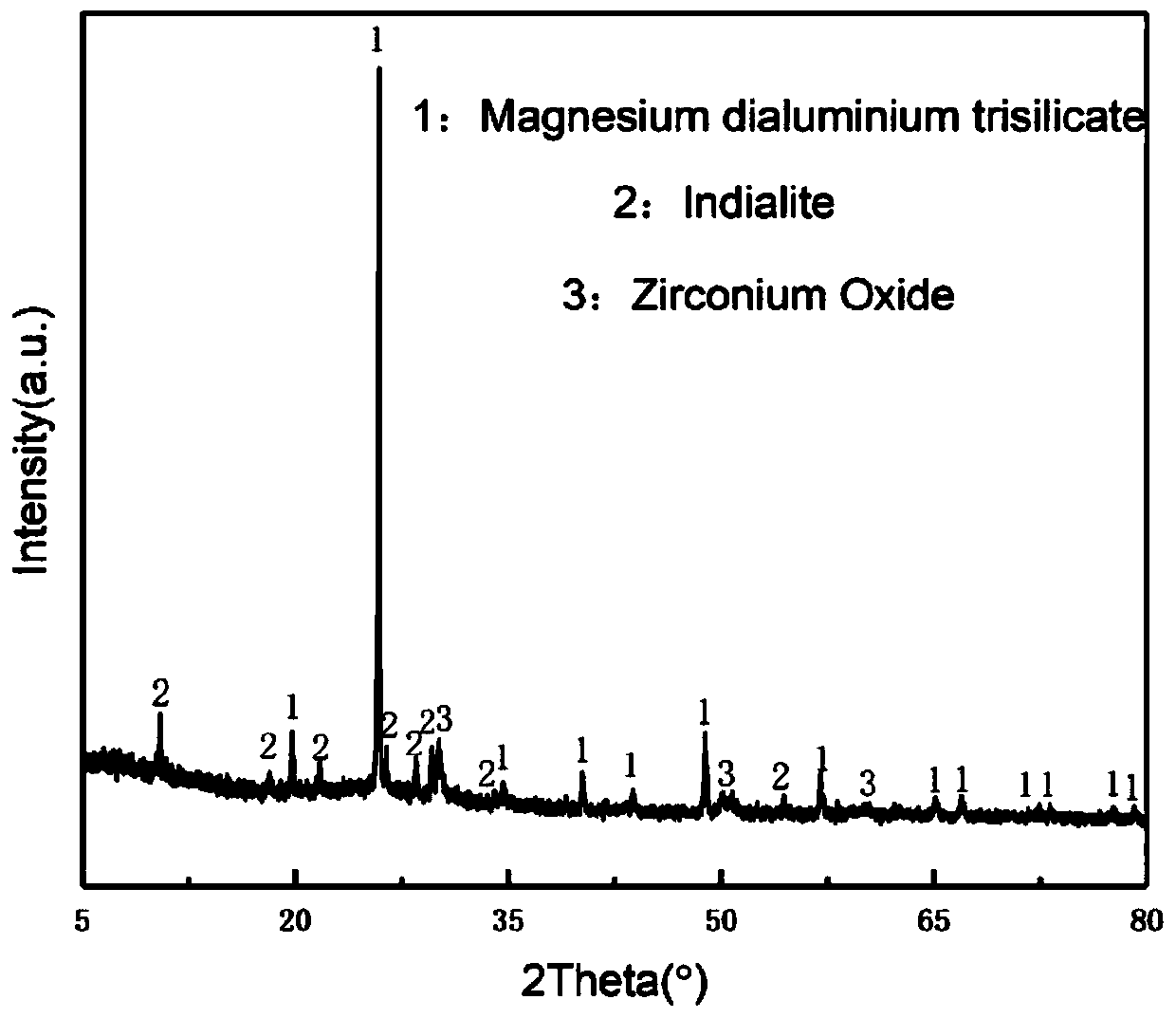

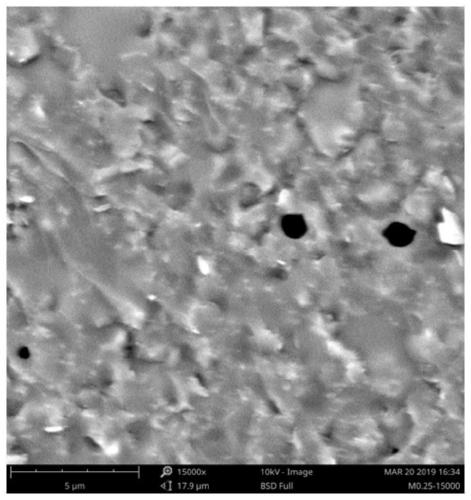

[0021] According to the formula MgO is 11wt%, CaO is 1wt%, Al 2 o 3 29wt%, SiO 2 49wt%, ZrO 2 9wt%, B 2 o 3 1wt%, accurately calculate the weight of the corresponding raw materials, after accurate weighing, ball mill for 2 to 4 hours to make it evenly mixed; after drying, put the mixture in a crucible to melt, heat up to 1550°C for 1 hour, and melt completely Finally, pour the molten solution into deionized water and water quench to obtain transparent and uniform glass slag; then wet the obtained glass slag through wet ball milling, dry to obtain glass powder, use deionized water and zirconium balls as the medium ball mill for 6 hours, dry, After sieving, a uniformly dispersed powder is obtained; after the powder is granulated and pressed, it is sintered at 900°C and kept for 1 hour to obtain a low-loss and low-thermal-expansion magnesium-aluminum-silicon-based glass-ceramic material.

[0022] The low-loss and low-thermal-expansion magnesium-aluminum-silicon-based glass-c...

Embodiment 2

[0024] According to the formula MgO is 13wt%, CaO is 2wt%, Al 2 o 3 27wt%, SiO 2 48wt%, ZrO 2 8wt%, B 2 o 3 2wt%, accurately calculate the weight of the corresponding raw materials, after accurate weighing, ball mill for 2 to 4 hours to make it evenly mixed; after drying, put the mixture in a crucible to melt, heat up to 1550°C for 1 hour, and melt completely Finally, pour the molten solution into deionized water and water quench to obtain transparent and uniform glass slag; then wet the obtained glass slag through wet ball milling, dry to obtain glass powder, use deionized water and zirconium balls as the medium ball mill for 6 hours, dry, After sieving, a uniformly dispersed powder is obtained; after the powder is granulated and pressed, it is sintered at 925°C and kept for 1 hour to obtain a low-loss and low-thermal-expansion magnesium-aluminum-silicon-based glass-ceramic material.

[0025] The low-loss and low-thermal-expansion magnesium-aluminum-silicon-based glass-c...

Embodiment 3

[0027] According to the formula MgO is 15wt%, CaO is 3wt%, Al 2 o 3 25wt%, SiO 2 47wt%, ZrO 2 7wt%, B 2 o 3 3wt%, accurately calculate the weight of the corresponding raw materials, after accurate weighing, ball mill for 2 to 4 hours to make it evenly mixed; after drying, put the mixture in a crucible to melt, heat up to 1500°C for 1.5 hours, and melt completely Finally, pour the molten liquid into deionized water and water quench to obtain transparent and uniform glass slag; then wet the obtained glass slag through wet ball milling, dry to obtain glass powder, use deionized water and zirconium balls as the medium ball mill for 7 hours, dry, After sieving, a uniformly dispersed powder is obtained; after the powder is granulated and pressed, it is sintered at 925° C. and kept for 1.5 hours to obtain a low-loss and low-thermal-expansion magnesium-aluminum-silicon-based glass-ceramic material.

[0028] The low-loss and low-thermal-expansion magnesium-aluminum-silicon-based g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com