Fluoride phosphor powder coating method based on atomic layer deposition technology

An atomic layer deposition, fluoride technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of low coating efficiency, long coating time, high energy consumption, etc., to improve the coating efficiency , The effect of improving water stability and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

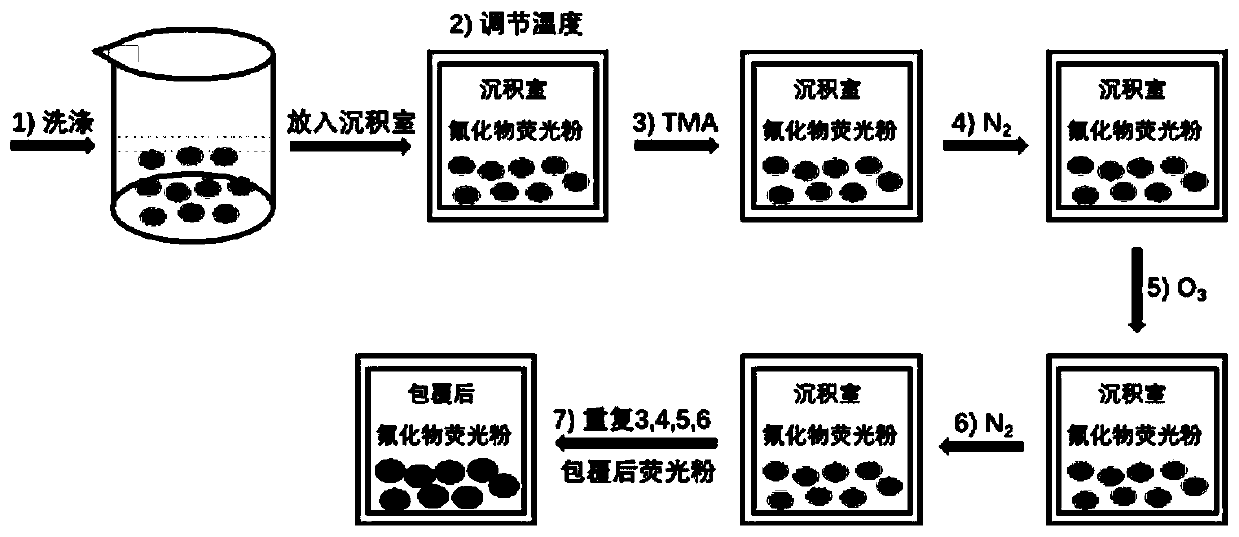

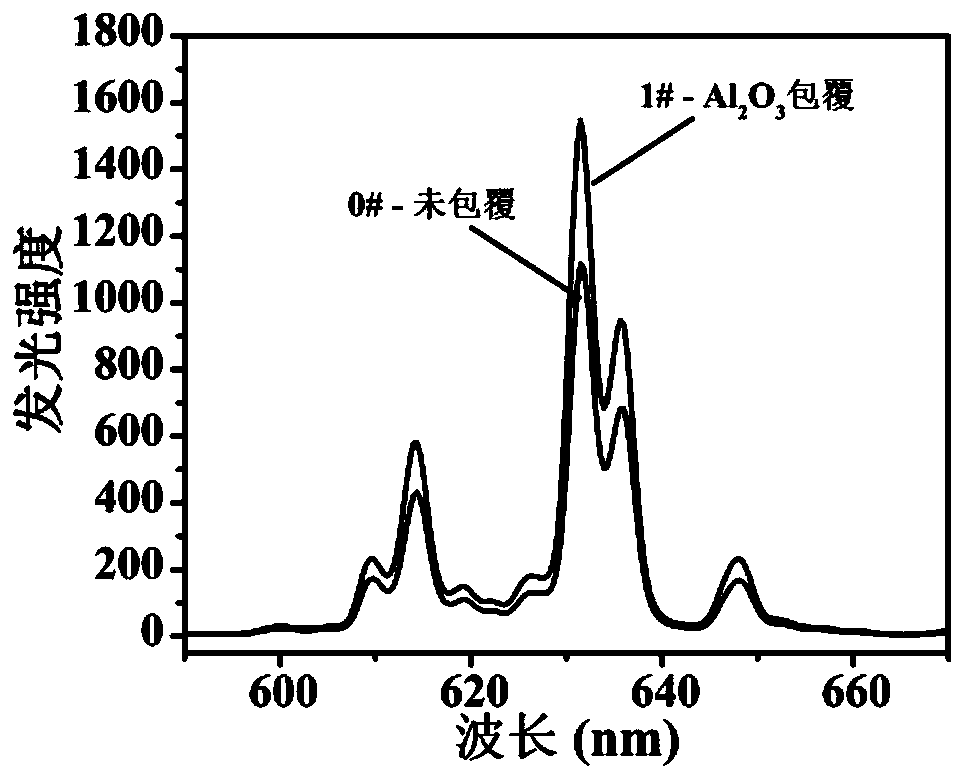

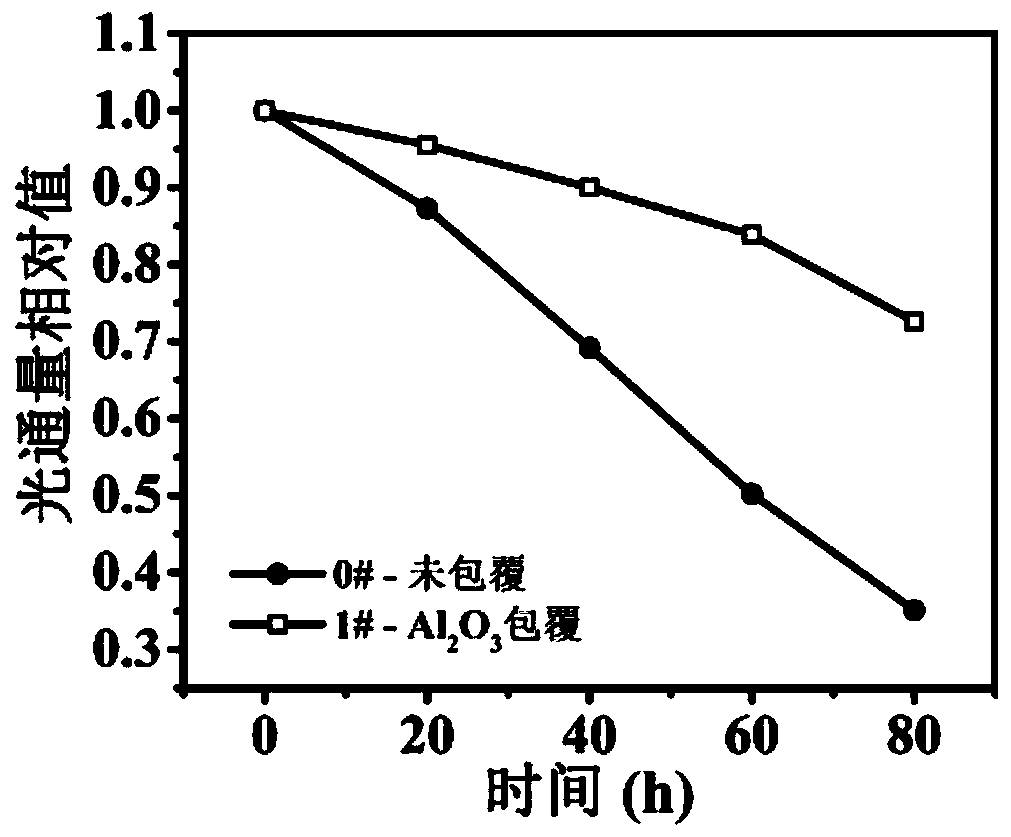

[0052] Select purchased washed and dried red fluoride phosphor ZYPF631Mn 4+ :K 2 GeF 6 , the uncoated sample is recorded as 0#, and another 1.5g aluminum oxide film coated on its surface for 30 cycles is recorded as 1#.

[0053] Put this 1.5g phosphor into the ALD deposition chamber, and then connect the phosphor deposition chamber to the equipment.

[0054] Introduce high-purity nitrogen to drive away the air in the system (deposition chamber and various channels).

[0055] Set the deposition parameters, turn on the high-purity nitrogen carrier gas of the atomic layer deposition equipment, the carrier gas flow rate is 150mL / min, the deposition temperature is 80°C, the precursor TMA reaction time is 30s, the purification time is 60s, and the precursor ozone reaction time is 30s , the purification time is 60s.

[0056] When the temperature of the deposition chamber reaches the preset deposition temperature, the reaction is started; the precursor and the phosphor are fully c...

Embodiment 2

[0059] 1.5 g of purchased washed and dried red fluoride phosphor ZYPF631 coated with aluminum oxide film for 20 cycles was recorded as 2#.

[0060] Put this 1.5g phosphor into the ALD deposition chamber, and then connect the phosphor deposition chamber to the equipment.

[0061] Introduce high-purity nitrogen to drive away the air in the system.

[0062] Set the deposition parameters, turn on the high-purity nitrogen carrier gas in the equipment, the carrier gas flow rate is 150mL / min, the deposition temperature is 80°C, the precursor TMA reaction time is 30s, the purification time is 80s, the precursor ozone reaction time is 30s, the purification The time is 80s.

[0063] When the temperature of the deposition chamber reaches the preset deposition temperature, the reaction is started; the precursor and the phosphor are fully contacted and reacted.

[0064] The deposition ends after 20 cycles, and the coated sample 2# is obtained.

Embodiment 3

[0066] 1.5 g of purchased washed and dried red fluoride phosphor ZYPF631 coated with 50-cycle aluminum oxide film on its surface is recorded as 3#.

[0067] Put this 1.5g phosphor into the ALD deposition chamber, and then connect the phosphor deposition chamber to the equipment.

[0068] Introduce high-purity nitrogen to drive away the air in the system.

[0069] Set the deposition parameters, turn on the high-purity nitrogen carrier gas in the equipment, the carrier gas flow rate is 150mL / min, the deposition temperature is 70°C, the precursor TMA reaction time is 10s, the purification time is 45s, the precursor ozone reaction time is 15s, the purification The time is 45s.

[0070] When the temperature of the deposition chamber reaches the preset deposition temperature, the reaction is started; the precursor and the phosphor are fully contacted and reacted.

[0071] The deposition ends after 50 cycles, and the coated sample 3# is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com