A magnetically enhanced phase-modified medical composite material bone repair bracket and its manufacturing method

A composite material and magnetic enhancement technology, applied in additive processing, medical science, prosthesis, etc., can solve the problems of unsatisfactory structural properties and brittleness of bone repair materials, and achieve good osteoinductive properties, good adsorption properties, and promote The effect of cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

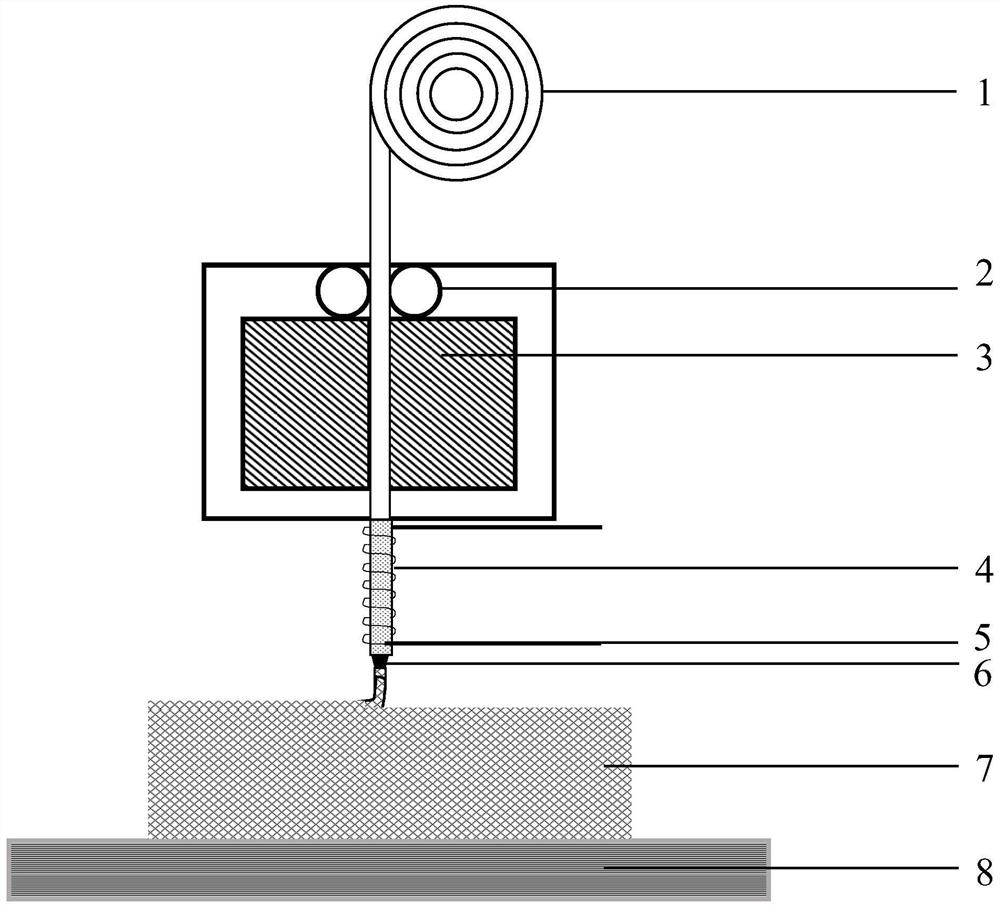

Image

Examples

Embodiment 1

[0034] A magnetic-enhanced phase-modified medical composite material bone repair bracket, with a pore size of 600 μm and a porosity of 80%, includes the following raw materials in terms of weight percentage:

[0035] Magnesium iron bimetallic composite oxide 1%,

[0036] Degradable polymer material polylactic acid 99%.

[0037] in:

[0038] The magnesium-iron bimetallic composite oxide is a roasted product of magnesium-iron hydrotalcite, which maintains the interlayer structure of hydrotalcite compounds, and has a particle size of 500 mesh.

[0039] The degradable polymer material is medical grade polylactic acid with an average molecular weight of 50,000 and a particle size of 2mm.

[0040] Its preparation steps are as follows:

[0041] 1) Preparation of magnesium iron hydrotalcite powder: prepare Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O blended salt solution containing 0.1mol / L Mg(NO 3 ) 2 and 0.02mol / L Fe(NO 3 ) 3 , and 400rpm magnetic stirring salt solution,...

Embodiment 2

[0046] A magnetic-enhanced phase-modified medical composite material bone repair bracket has a pore diameter of 300 μm and a porosity of 60%, and includes the following raw materials according to weight percentage:

[0047] Magnesium iron bimetallic composite oxide 25%,

[0048] Degradable polymer material polycaprolactone 75%.

[0049] in:

[0050] The magnesium-iron bimetallic composite oxide is a roasted product of magnesium-iron hydrotalcite, which maintains the interlayer structure of hydrotalcite compounds, and has a particle size of 800 mesh.

[0051] The degradable polymer material is medical grade polycaprolactone with an average molecular weight of 500,000 and a particle size of 3 mm.

[0052] Its preparation steps are as follows:

[0053] 1) Preparation of magnesium iron hydrotalcite powder: prepare Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O blended salt solution containing 0.3mol / L Mg(NO 3 ) 2 and 0.1mol / L Fe(NO 3 ) 3 , and 1000rpm magnetic stirring sa...

Embodiment 3

[0058] A magnetically enhanced phase-modified medical composite material bone repair bracket, the pore diameter is 500 μm, the porosity is 70%, and the following raw materials are included according to weight percentage:

[0059] Magnesium iron bimetallic composite oxide 10%,

[0060] Degradable polymer material polyglycolide 90%.

[0061] in:

[0062] The magnesium-iron bimetal composite oxide is a roasted product of magnesium-iron hydrotalcite, which maintains the interlayer structure of hydrotalcite compounds, and has a particle size of 600 mesh.

[0063] The degradable polymer material is medical grade polyglycolide with an average molecular weight of 300,000 and a particle size of 2.5 mm.

[0064] Its preparation steps are as follows:

[0065] 1) Preparation of magnesium iron hydrotalcite powder: prepare Mg(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O blended salt solution containing 0.15mol / L Mg(NO 3 ) 2 and 0.04mol / L Fe(NO 3 ) 3 , and 400rpm magnetic stirring sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com