Preparation method of porous silicon aluminum phosphorus carrier hydrogenation catalyst and application thereof to preparation of biofuel

A technology of hydrogenation catalyst and porous structure, which is applied in the direction of biological raw materials, catalyst carriers, chemical instruments and methods, etc., can solve the problems of no template method and few reports, so as to reduce production costs, avoid environmental pollution, and be green and environmentally friendly. The effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

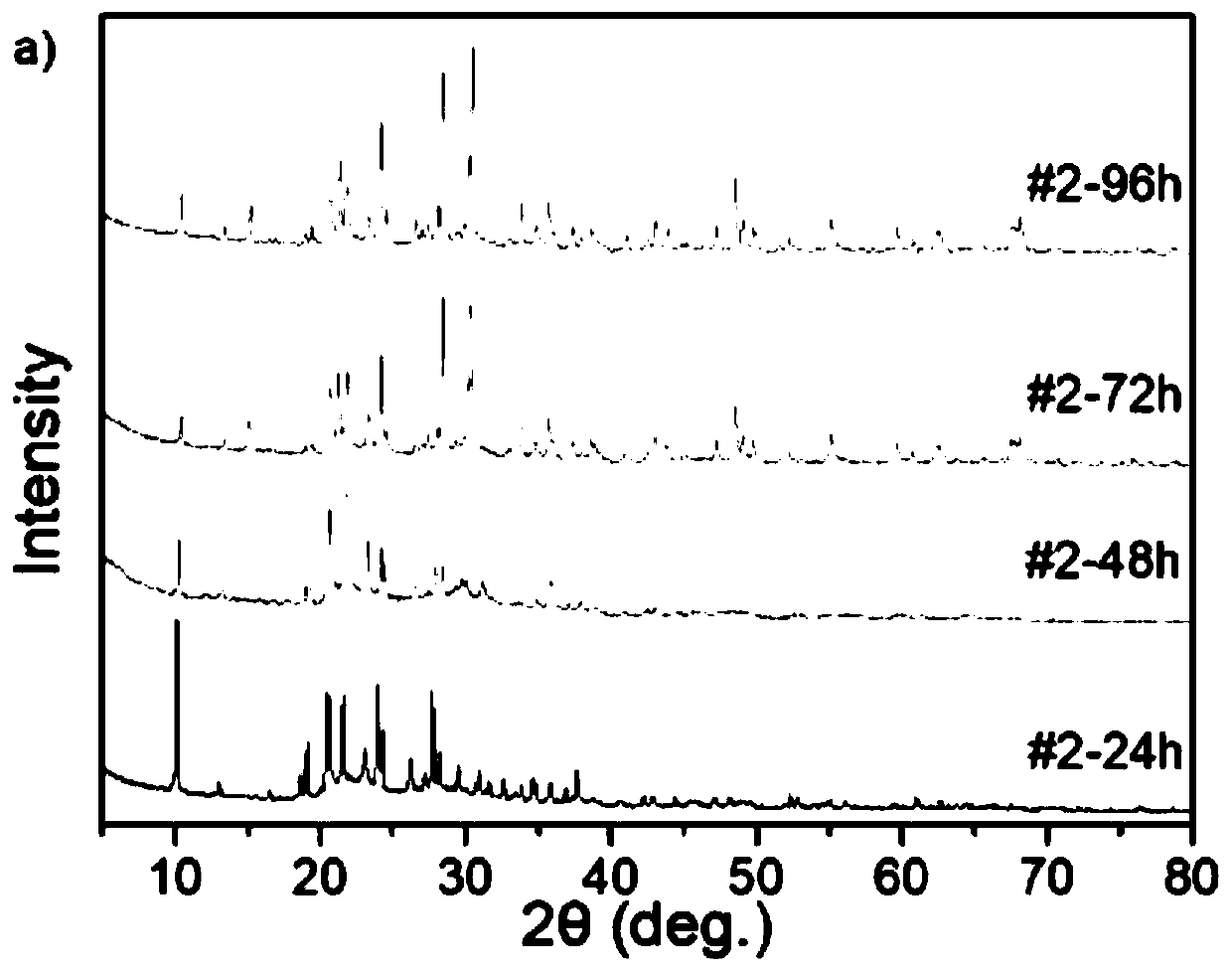

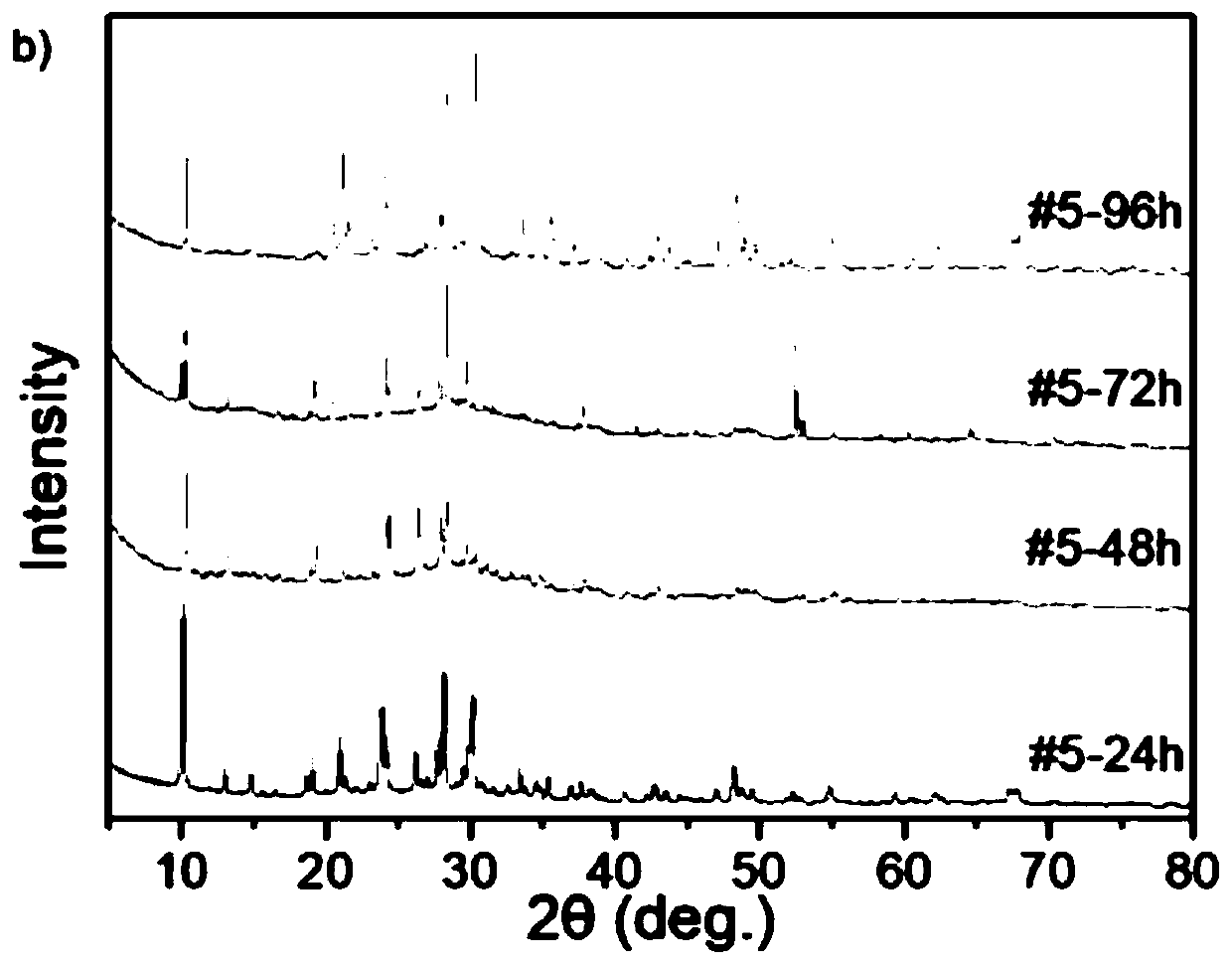

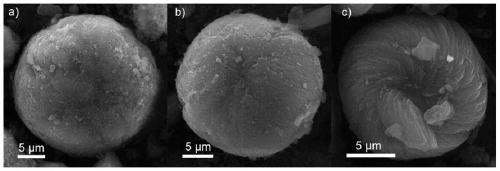

[0039] The preparation process of silicon-aluminum-phosphorus carrier with porous structure, adding alkali source to the mixed solution of silicon source, aluminum source, phosphorus source and water for reaction, water, silicon source, aluminum source, phosphorus source and alkali source are expressed in moles of oxide The mixture is mixed at a ratio of 50-100:1:1:0.1-1:0.5-2. After crystallization, the primary product of the silicon-aluminum-phosphorus carrier with a porous structure is obtained, and then treated with an ion exchanger to obtain a silicon-aluminum-phosphorus carrier with a porous structure. Wherein, the silicon source can be one of sodium silicate, silica sol, tetraethyl orthosilicate, and white carbon black; the alkali source can be one of potassium hydroxide, sodium hydroxide, and calcium hydroxide; the phosphorus source is phosphoric acid. The ion exchanger used during ion exchange can be one of ammonium nitrate, ammonium chloride, ammonium sulfate, hydroc...

Embodiment 1

[0055] The preparation of embodiment 1. hydrodeoxygenation catalyst comprises the following steps:

[0056] (1) The preparation method of silicon-aluminum-phosphorus carrier without template method: mix 12.5g deionized water, 2.21g phosphoric acid, 1.38g pseudo-boehmite, 0.77g silica sol and 4g sodium hydroxide, and stir at 20°C 3h. Then the mixture was transferred to a high-pressure crystallization kettle lined with polytetrafluoroethylene, sealed and crystallized at 180°C for 96 hours. After the reaction was completed, the solid product was left to stand and cooled, and the solid product was centrifuged and dried to obtain the initial product. Then use an ion exchanger to ion-exchange the product, add the solid to 0.8mol / L ammonium nitrate solution, the mass ratio of liquid to solid is 15:1, fully stir at 25°C for 12h, stop stirring and then centrifuge and wash Drying is recorded as one ion exchange, and a total of 2 exchanges. The final product obtained is denoted as carr...

Embodiment 2

[0058] Embodiment 2. The preparation of hydrodeoxygenation catalyst comprises the following steps:

[0059] (1) Preparation method of silicon-aluminum-phosphorus carrier by template-free method: mix 15g of deionized water, 2.21g of phosphoric acid, 1.38g of pseudo-boehmite, 0.38g of silica sol and 4g of potassium hydroxide, and stir at 20°C for 3h . Then the mixture was transferred to a high-pressure crystallization kettle lined with polytetrafluoroethylene, sealed and crystallized at 180°C for 96 hours. After the reaction was completed, the solid product was left to stand and cooled, and the solid product was centrifuged and dried to obtain the initial product. Then use an ion exchanger to ion-exchange the product, add the solid to 0.8mol / L ammonium nitrate solution, the mass ratio of liquid to solid is 15:1, fully stir at 25°C for 12h, stop stirring and then centrifuge and wash Drying is recorded as one ion exchange, and a total of 2 exchanges. The final product obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com