A kind of non-cured rubber asphalt waterproof coating and preparation method thereof at room temperature

A technology of rubber asphalt and waterproof coatings, which is applied in the direction of asphalt coatings, polyester coatings, coatings, etc., and can solve problems such as high requirements for machinery and tools, difficult construction, and difficult scraping construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

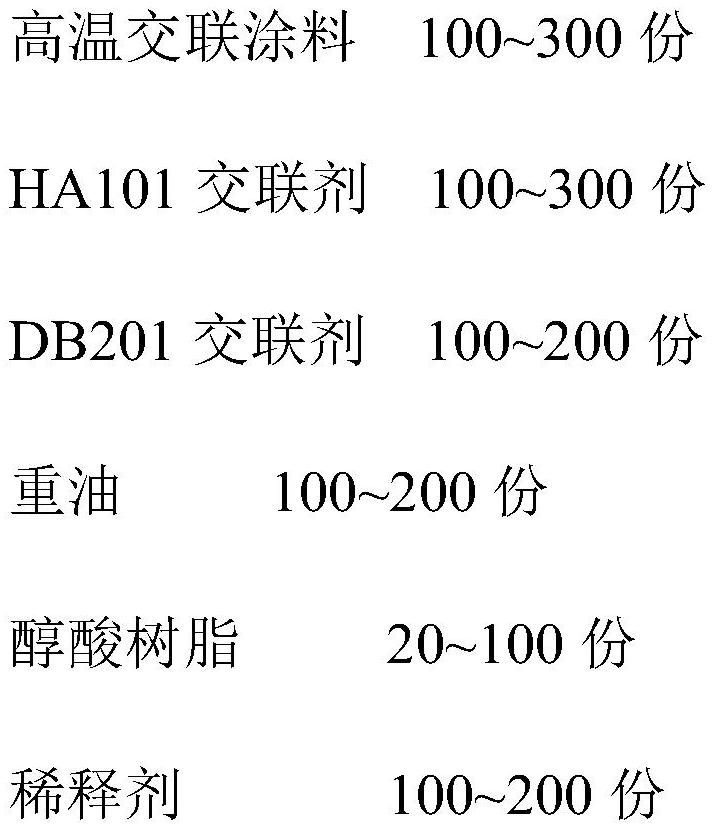

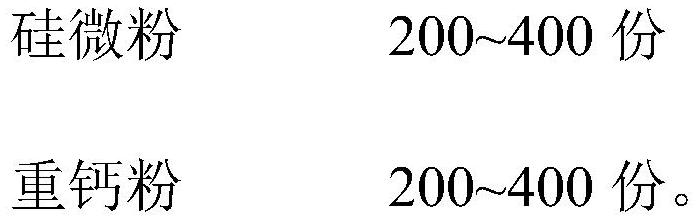

Method used

Image

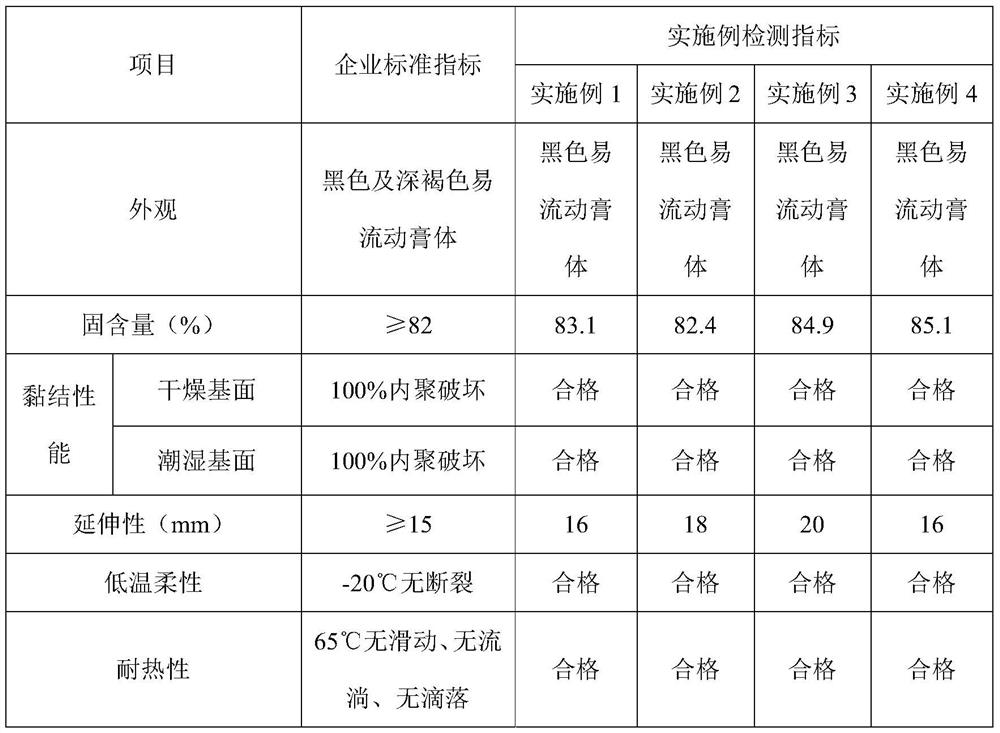

Examples

preparation example Construction

[0030] The preparation method of above-mentioned HA101 crosslinking agent is as follows: Vegetable oil pitch 50% (by weight percentage, the same below), polyester waste 35%, glycerol 14.9%, lithium hydroxide 0.1%, add vegetable oil pitch Stir in the kettle and heat up to 180°C, add glycerin and lithium hydroxide, then heat up to 210°C, add polyester waste and heat up to 240°C, keep warm for 2 hours, then heat up to 270-280°C, keep warm for 3 hours, and cool down After reaching 200°C, add high-boiling point aromatic oil and cool to room temperature to obtain HA101 crosslinking agent.

[0031]The DB201 crosslinking agent is an acrylic polymer, and its Tg<-20°C. The acrylate polymer is formed by copolymerization of the following components by mass content: styrene 8.5%, ethyl acrylate 9.5%, butyl acrylate 10%, methyl methacrylate 10%, acrylic acid 1.5%, acrylic acid-2 - 15% of ethylhexyl ester, 1% of initiator, 2% of emulsifier, 1% of ammonia water, and the balance is water.

...

Embodiment 1

[0039] Embodiment 1: described diluent is ethyl acetate. The asphalt is 90# asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com