Refrigerant, and compressor and air conditioning device or heat pump unit using same

A technology for heat pump devices and air conditioners, applied in the field of compressors and air conditioners or heat pump devices, can solve problems such as high global warming potential, high ozone depletion potential, and large greenhouse effect, and achieve solutions to ozone layer destruction, good energy efficiency, The effect of solving the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

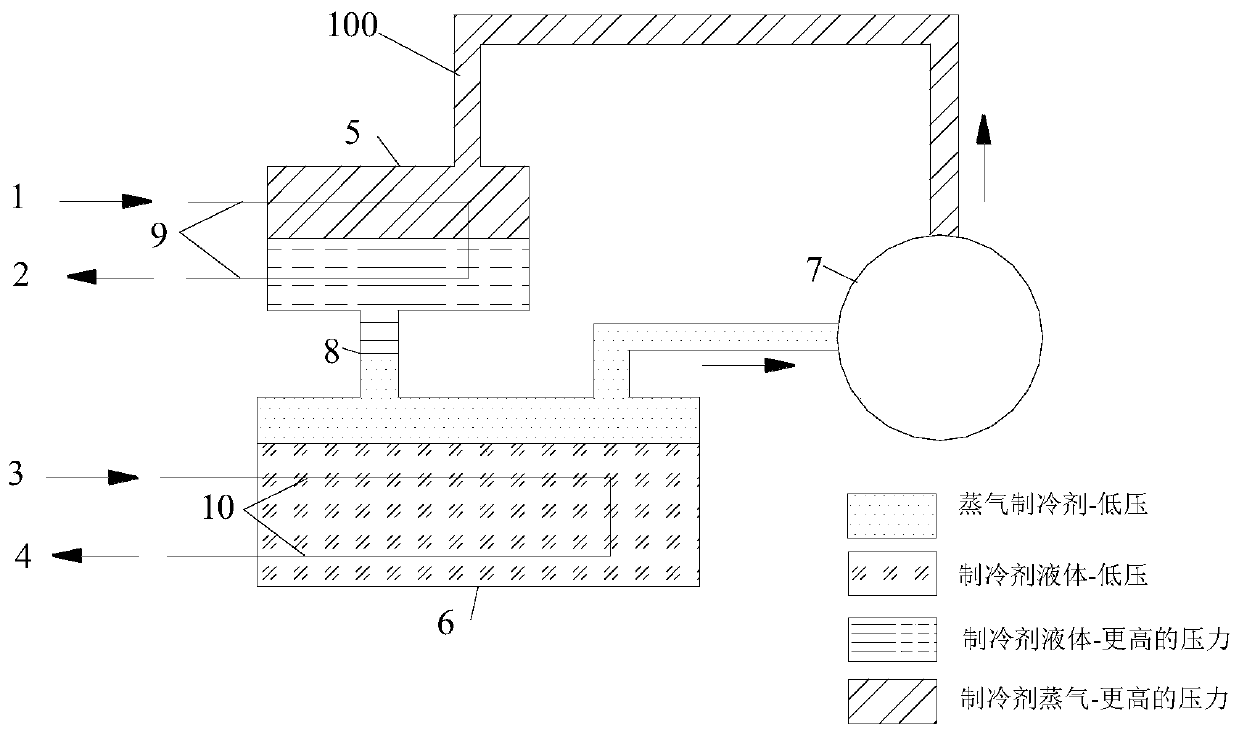

[0049] Embodiment 1, such as figure 1 As shown, preferably,

[0050] Including a compressor 7, a condenser 5 and an evaporator 6, the compressor 7, the condenser 5 and the evaporator 6 are sequentially connected in series in the refrigeration cycle line 100, the compressor 7 The refrigerant is communicated into the condenser 5 through the exhaust port, the refrigerant at the outlet of the condenser 5 is communicated into the evaporator 6, and the refrigerant at the outlet of the evaporator 6 is communicated into the compressor 7 in. This is the preferred structural form of the flooded evaporator of the present invention, and coolers with a cooling capacity higher than 700kW generally use a flooded evaporator, in which the refrigerant in the evaporator and condenser surrounds coils or other conduits to cool the medium (i.e. the refrigerant is on the shell side). A flooded evaporator requires a higher refrigerant load, but produces a closer approach temperature and is more ef...

no. 2 approach

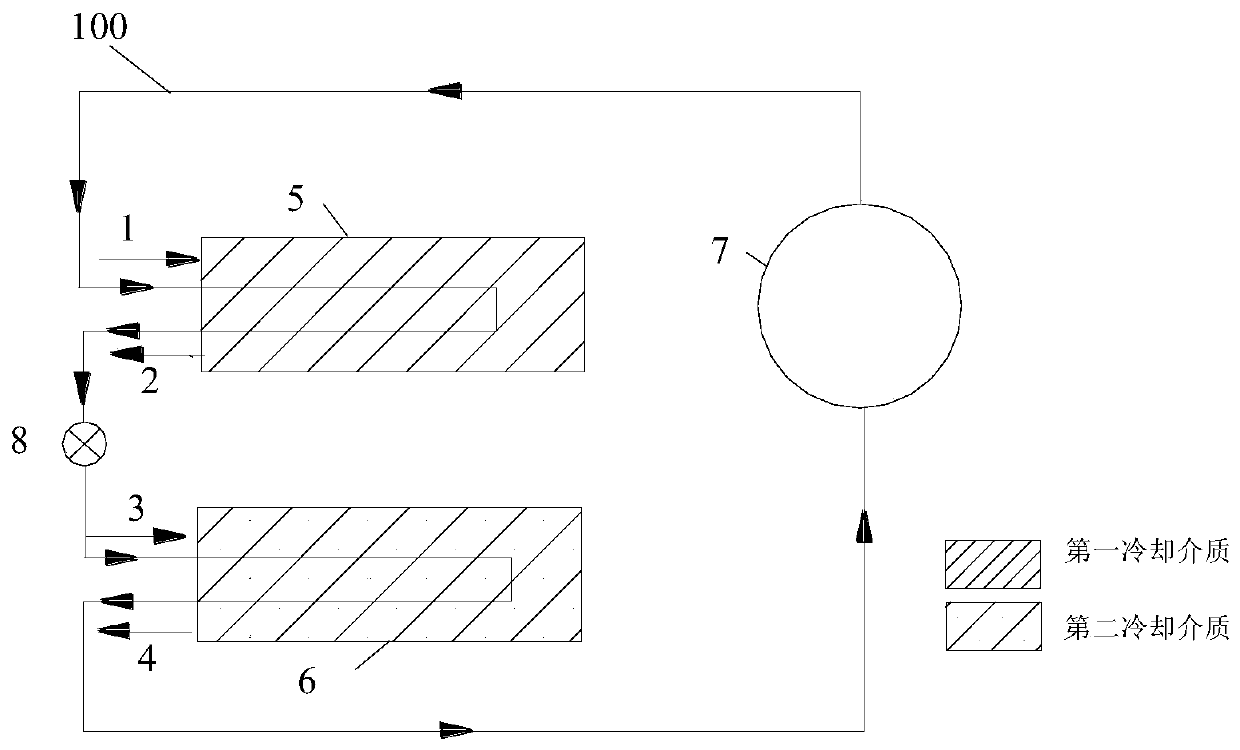

[0056] The second embodiment, such as figure 2 As shown, preferably,

[0057] Including a compressor 7, a condenser 5 and an evaporator 6, the compressor 7, the condenser 5 and the evaporator 6 are sequentially connected in series in the refrigeration cycle line 100, the compressor 7 The refrigerant enters the refrigeration cycle pipeline 100 through the exhaust port, and then the refrigeration cycle pipeline 100 penetrates into the condenser 5, and then the refrigeration cycle pipeline 100 passes through the condenser 5 out and penetrate into the evaporator 6 , and then the refrigeration cycle pipeline 100 penetrates out of the evaporator 6 and enters into the compressor 7 .

[0058] Preferably,

[0059] The condenser 5 is fed with a first cooling medium, and the first cooling medium exchanges heat with the refrigerant in the refrigeration cycle line in the condenser 5, and the condenser 5 includes a second a cooling medium inlet 1 and a first cooling medium outlet 2; and...

Embodiment

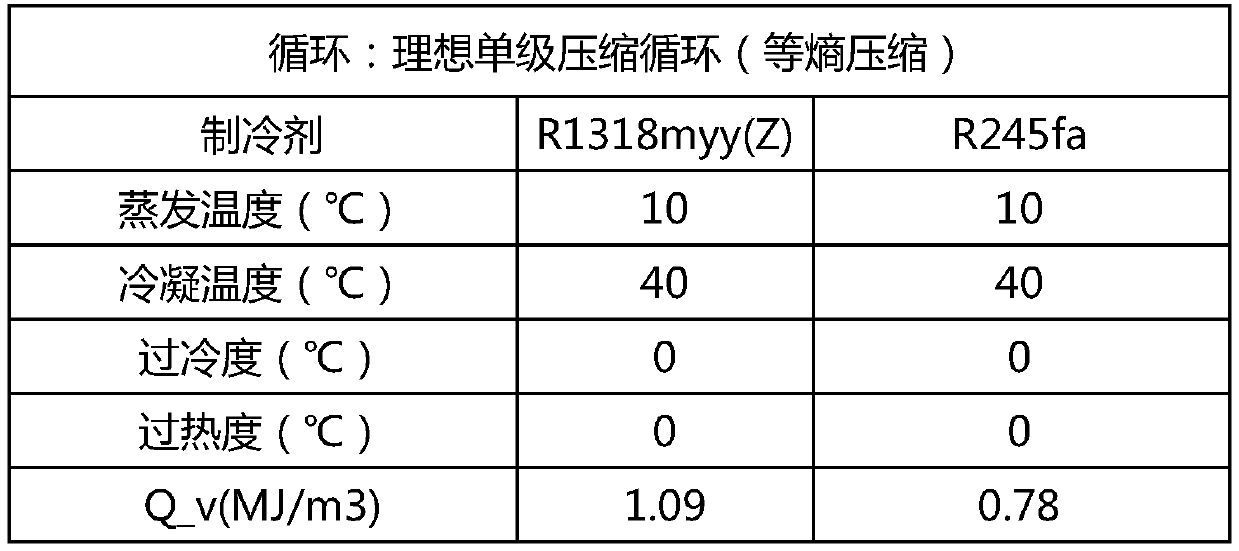

[0068] Table 1 shows the performance of R1318myy(Z) compared to R245fa under conditions typical for centrifugal coolers. In Table 1, Q_v is the volume capacity. It can be seen from Table 1 that the Q_v value of the new refrigerant R1318myy(Z) of the present invention is greater than the Q_v value of R245fa, so the new refrigerant R1318myy(Z) of the present invention can Compared with R245fa, it improves compression efficiency and refrigeration cycle efficiency.

[0069] Table 1

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com