A high-sensitivity temperature sensing method based on near-infrared fluorescence

A high-sensitivity, sensing method technology, applied in the direction of physical/chemical change thermometers, thermometers, instruments, etc., can solve the problems of weakened fluorescence intensity of up-conversion fluorescence, low fluorescence efficiency and quantum yield, difficult to analyze and process data, etc. , to achieve the effect of improving temperature measurement accuracy and sensitivity, improving accuracy and sensitivity, and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a high-sensitivity temperature sensing method for near-infrared fluorescence, which includes:

[0030] Step 1. Accurately weigh the drug according to the molar ratio (mmol%), the ratio is 50Na 2 CO 3 -200WO 3 -49.5Y 2 o 3 -5Yb 2o 3 -0.5Er 2 o 3 , Pour the raw material into the agate mortar, grind it with a grinding rod for 30 minutes, use a tablet machine to press the mixture into a sheet material, then put it in a dry and clean porcelain boat, put it in a high-temperature furnace, and keep it at 1000°C After 6 hours, let it cool naturally to room temperature after the end of the program, and finally wrap the NaY(WO 4 ) 2 : Yb 3+ / Er 3+ samples.

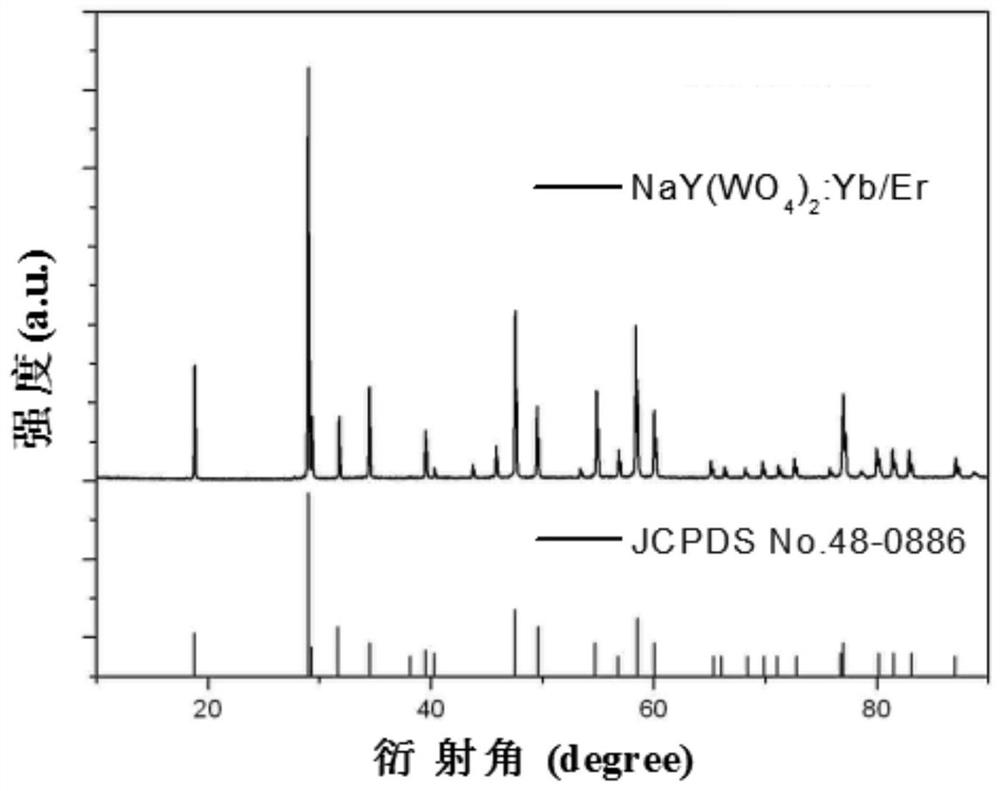

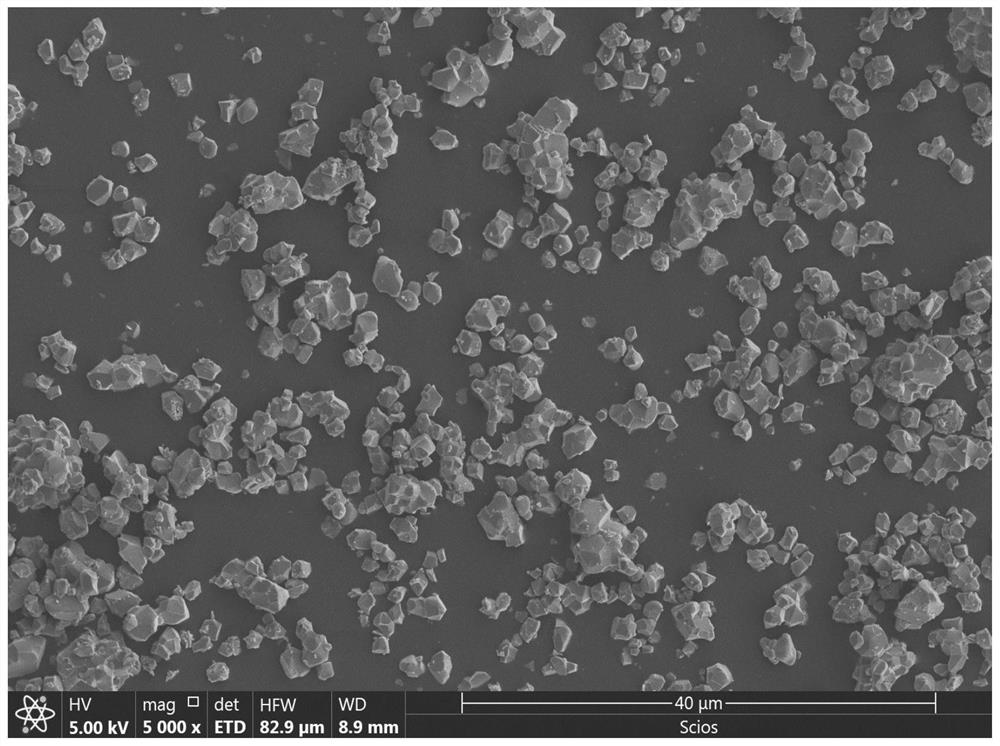

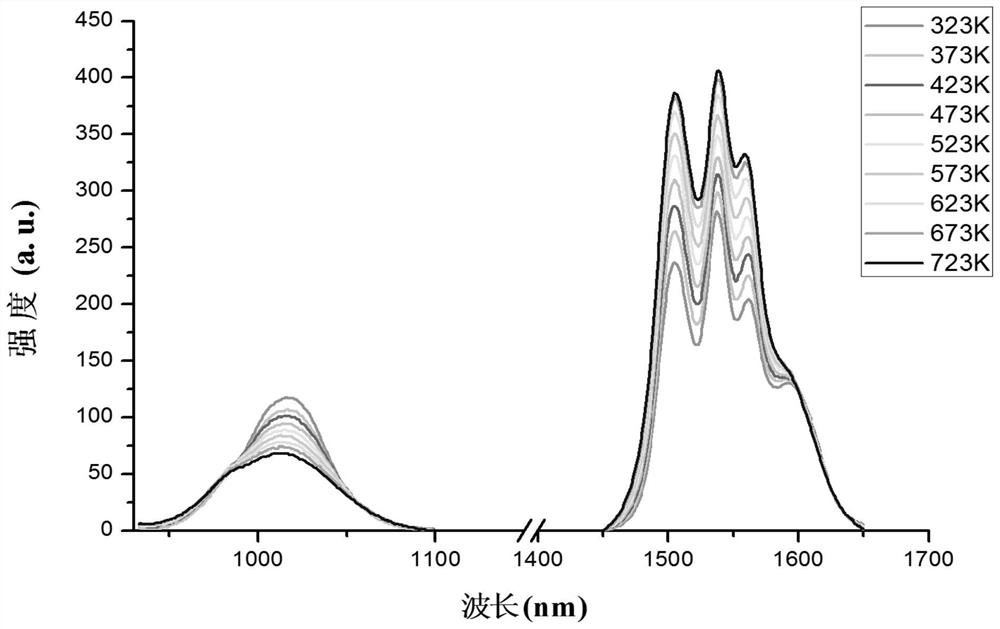

[0031] For the prepared NaY(WO 4 ) 2 : Yb 3+ / Er 3+ The sample is characterized, and its test results of X-ray diffraction pattern analysis (XRD) and scanning electron microscope pattern analysis (SEM) are as follows respectively figure 1 , 2 shown. It can be seen from the XRD patter...

Embodiment 2

[0046] This embodiment provides a high-sensitivity temperature sensing method for near-infrared fluorescence, which includes:

[0047] Step 1. Accurately weigh the drug according to the molar ratio (mmol%), the ratio is 100CaCO 3 -100MoO 3 -5Yb 2 o 3 -0.5Er 2 o 3 , put the raw material into the agate mortar, grind it with a grinding rod for 30 minutes, press the mixture into a sheet material with a tablet machine, put it in a dry and clean porcelain boat, put it in a high-temperature furnace, and keep it at 1100°C After 7 hours, after the end of the program, let it cool down to room temperature and take it out, and finally wrap the CaMoO with tin foil 4 : Yb 3+ / Er 3+ samples.

[0048] Step two, the CaMoO 4 : Yb 3+ / Er 3+ The sample is placed on a controllable heating stage, the laser with a center wavelength of 915nm is selected as the excitation light source, and the optical path is adjusted so that the excitation light source, the center of the sample and the lig...

Embodiment 3

[0052] This embodiment provides a high-sensitivity temperature sensing method for near-infrared fluorescence, which includes:

[0053] Step 1. Accurately weigh the drug according to the molar ratio (mmol%), the ratio is 89CaCO 3 -100WO 3 -5Yb 2 o 3 -0.5Er 2 o 3 , Pour the raw material into the agate mortar, grind it with a grinding rod for 30 minutes, use a tablet machine to press the mixture into a sheet material, then put it in a dry and clean porcelain boat, put it in a high-temperature furnace, and keep it at 1000°C After 7 hours, after the end of the program, let it cool down to room temperature and take it out, and finally wrap CaWO with tin foil 4 :Yb 3+ / Er 3+ samples.

[0054] Step 2, the CaWO 4 :Yb 3+ / Er 3+ The sample is placed on a controllable heating stage, the laser with a center wavelength of 915nm is selected as the excitation light source, and the optical path is adjusted so that the excitation light source, the center of the sample and the light e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com