Germanium-silicon-based gallium arsenide material and preparation method thereof, and application of germanium-silicon-based gallium arsenide material

A silicon-based gallium arsenide and gallium arsenide technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor thermal conductivity, size mismatch between wafer and silicon wafer, and complex growth structure. Achieve the effect of releasing stress and suppressing anti-phase domain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] This embodiment is used to illustrate the germanium-silicon-based gallium arsenide material and its preparation method of the present invention.

[0044] (1) Form a periodic groove structure on a silicon substrate:

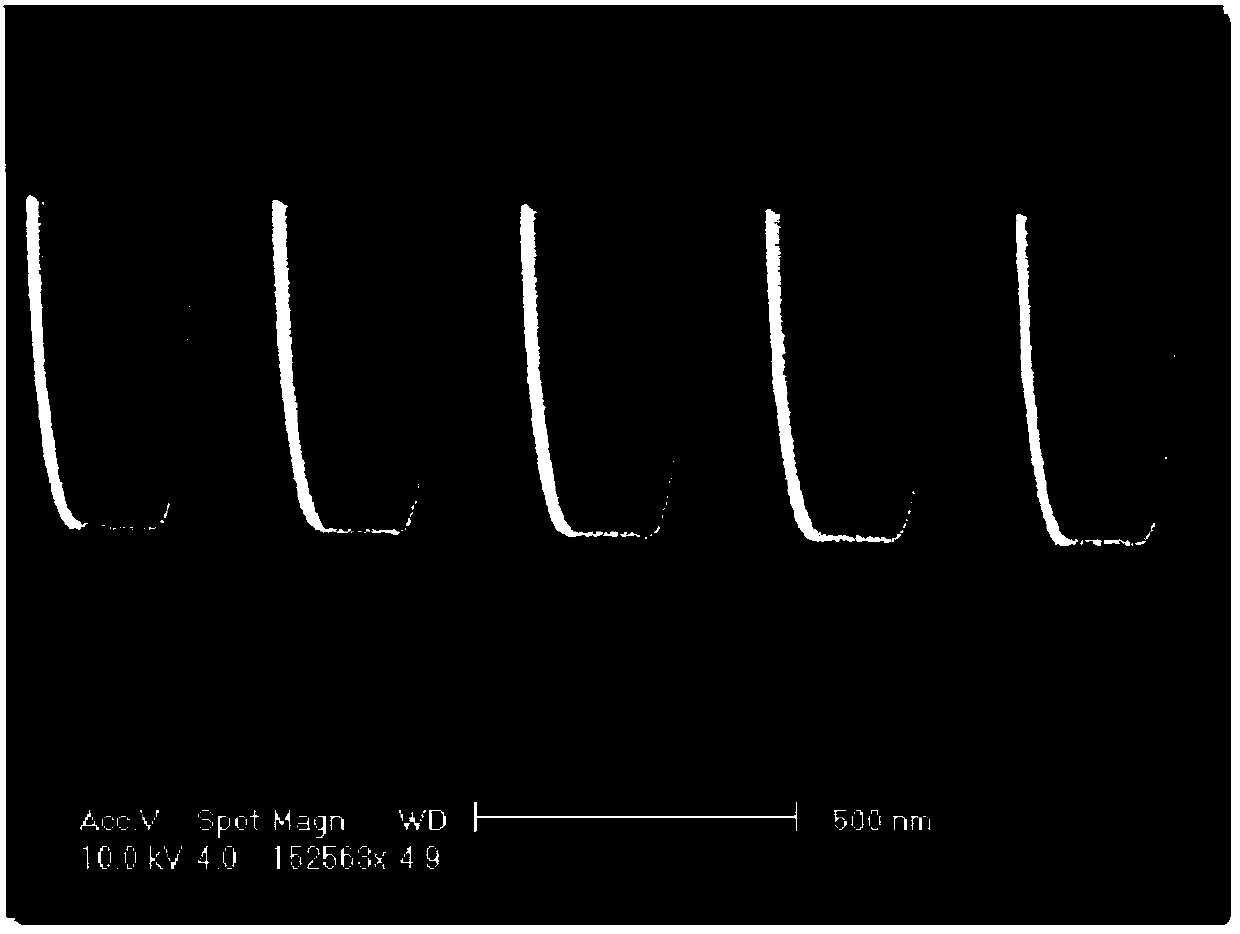

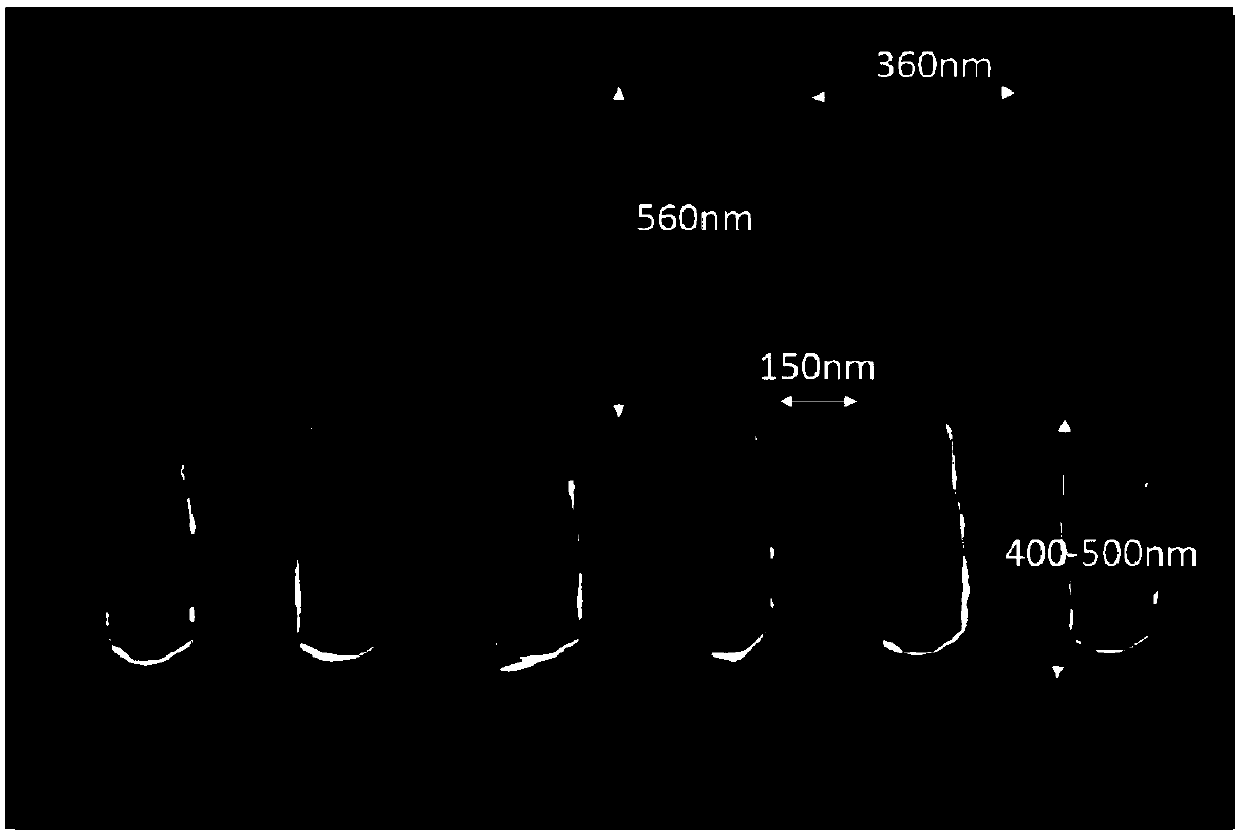

[0045] Growth of SiO on the surface of silicon (100) substrate by plasma-enhanced chemical vapor deposition 2 mask; using deep ultraviolet lithography on SiO 2 Build a periodic groove structure along the (110) direction on the mask; complete the preparation of a silicon substrate with a periodic groove structure on the surface by reactive ion etching technology; use hydrofluoric acid to remove the surface SiO 2 mask;

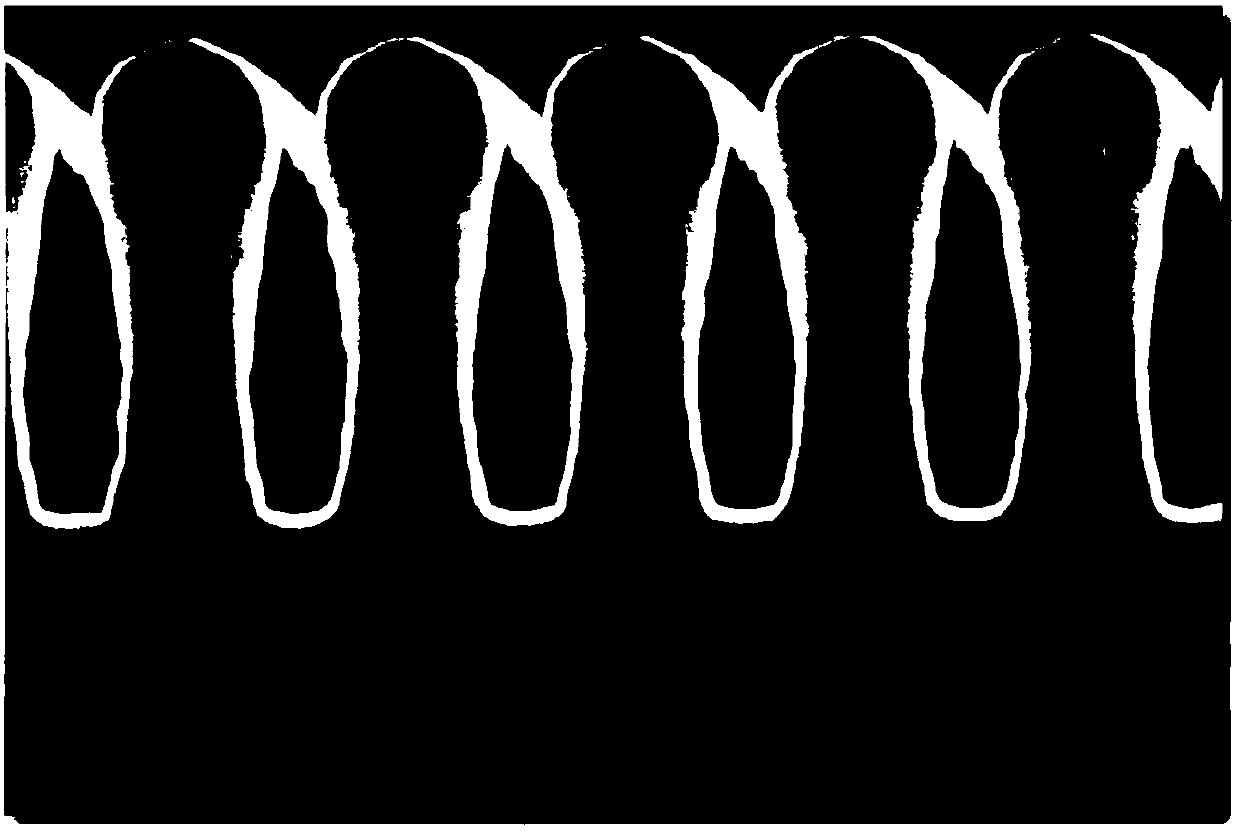

[0046](2) Using molecular beam epitaxy growth technology, a 560nm germanium intermediate layer is epitaxially grown on a silicon substrate with a periodic groove structure on the surface, the growth temperature is 340°C, and the surface is a germanium (113) crystal plane with sawtooth shape graph structure;

[0047] (3) Using two-step met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com