A titanium-silicon phosphotungstate composite material with mesoporous structure and preparation method thereof

A technology of silicon composite materials and titanium phosphotungstate, applied in the field of composite materials, can solve the problems of long experimental period and complicated operation process, and achieve the effect of short experimental period, simple operation and improved hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

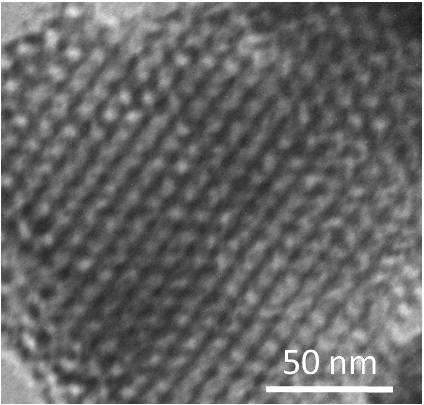

Image

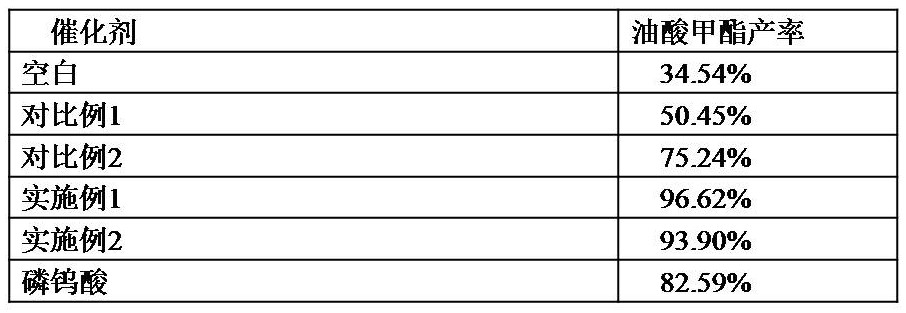

Examples

Embodiment 1

[0024] A preparation method of a titanium-silicon phosphotungstate composite material with a mesoporous structure, comprising the following steps:

[0025] (1) Weigh 1.0 g of P123, dissolve it in 30 mL of dilute hydrochloric acid with a concentration of 2 mol / L, and stir magnetically at 40 °C until P123 is completely dissolved to obtain a clear solution containing the structure-directing agent;

[0026] (2) Weigh 0.6 g H 3 PW 12 o 40 , and then dissolved it in 7.5 mL distilled water, and added the dissolved phosphotungstic acid aqueous solution dropwise to the clear solution prepared in step (1), and stirred thoroughly for 2 hours to obtain a milky white solution;

[0027] (3) Weigh 0.43 g of titanium trichloride hydrochloric acid solution with a mass fraction of 17%, and add it to the milky white solution prepared in step (2), and then add 1.32 mL of 98% normal Ethyl silicate, and then add dropwise 1,2-bis(triethoxysilyl)ethane with a mass fraction of 97%, said ethyl ortho...

Embodiment 2

[0031] A preparation method of a titanium-silicon phosphotungstate composite material with a mesoporous structure, comprising the following steps:

[0032] (1) Weigh 1.0 g of P123, dissolve it in 30 mL of dilute hydrochloric acid with a concentration of 2 mol / L, and stir magnetically at 40 °C until P123 is completely dissolved to obtain a clear solution containing the structure-directing agent;

[0033] (2) Weigh 0.4 g H 3 PW 12 o 40 , and then dissolved it in 5 mL of distilled water, and added the dissolved aqueous solution of phosphotungstic acid dropwise to the clear solution prepared in step (1), and stirred thoroughly for 2 hours to obtain a milky white solution;

[0034] (3) Weigh 0.43 g of titanium trichloride hydrochloric acid solution with a mass fraction of 17%, and add it to the milky white solution prepared in step (2), and then add 1.32 mL of 98% normal Ethyl silicate, and then 0.61 mL of 1,2-bis(triethoxysilyl)ethane with a mass fraction of 97% was added dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com