Multifunctional surface optimization agent for concrete and preparation method thereof

A multi-functional, concrete technology, applied in the field of materials, can solve the problems of large performance differences and no evaluation methods, and achieve the effects of stable performance, fast film forming speed, and environmentally friendly materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

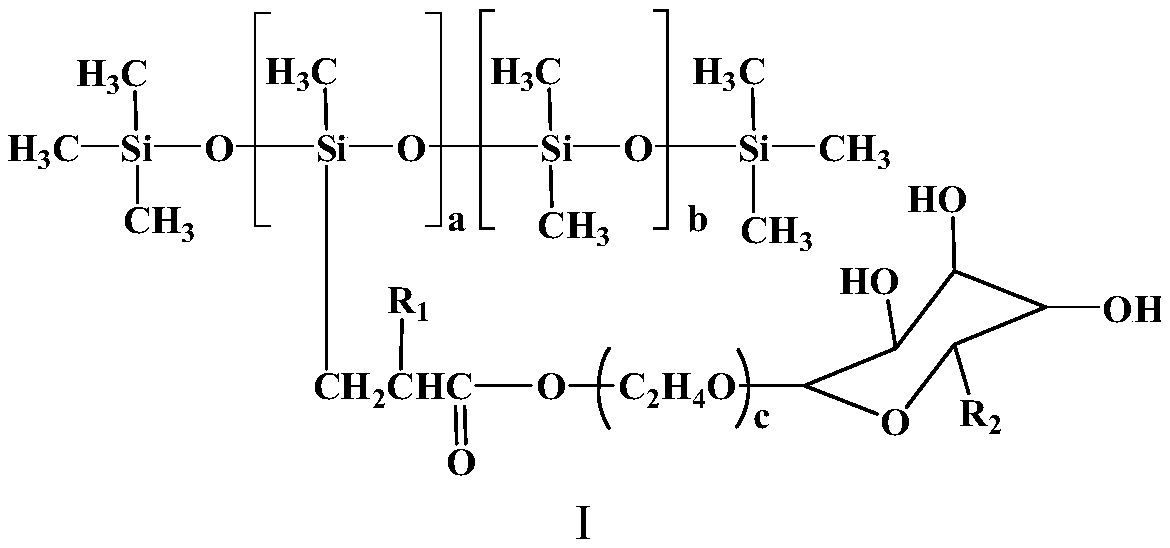

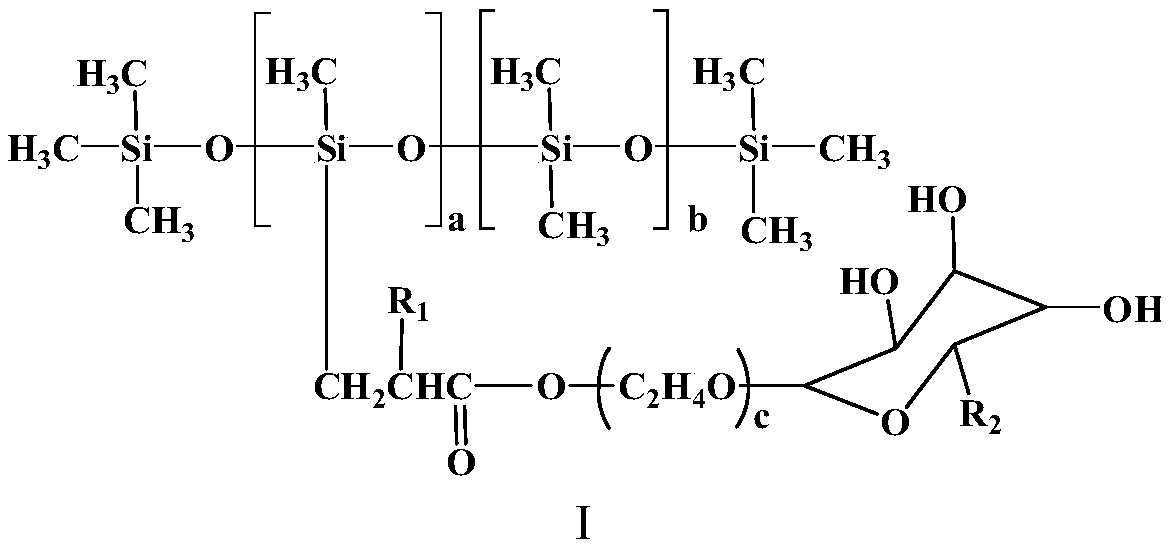

Method used

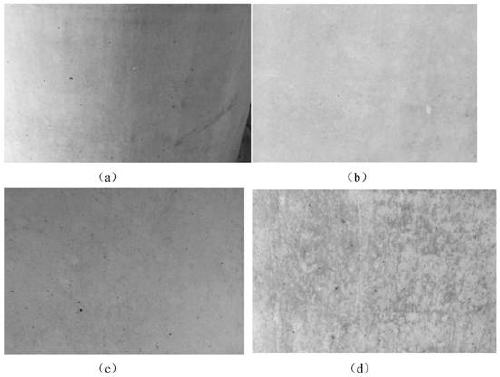

Image

Examples

Embodiment 1

[0026] A preparation method of multifunctional surface optimizer for concrete is as follows:

[0027] Weigh 100g of 58-degree palm oil into a round-necked flask, add 5g of sorbitan fatty acid ester-80, stir, heat to 40°C, dissolve 5g of polyoxyethylene sorbitan fatty acid ester, 1g of phosphoric acid Diester, 1g butyl acrylate, 1g carboxylate, 1g polyvinyl alcohol, 0.5g polyacrylamide, 0.5g xanthan gum and 40°C water (emulsified water) are slowly added dropwise to the round neck flask until the phase inversion of the emulsion . Increase the rotation speed to 150r / min, and slowly pour in the remaining water. After stirring for 20 minutes, reduce the rotating speed to 60r / min, and discharge after cooling to obtain the multifunctional surface optimizer YH-1.

Embodiment 2

[0029] A preparation method of multifunctional surface optimizer for concrete is as follows:

[0030] Weigh 100g of 58-degree palm oil and pour it into a round-necked flask, add 10g of sorbitan fatty acid ester-80, stir, heat to 40°C, dissolve 10g of polyoxyethylene sorbitan fatty acid ester, 1g of phosphoric acid Monoester, 1 g of carboxylate, 1 g of polysiloxane, and 1 g of polyacrylamide in water (emulsified water) at 40° C. were slowly added dropwise into a round-necked flask until the phase of the emulsion was inverted. Increase the rotation speed to 200r / min, and slowly pour in the remaining water. After stirring for 20 minutes, reduce the rotation speed to 60r / min, and discharge the material after cooling to obtain the multifunctional surface optimizer YH-2.

Embodiment 3

[0032] A preparation method of multifunctional surface optimizer for concrete is as follows:

[0033] Weigh 100g of 58-degree palm oil and pour it into a round-necked flask, add 10g of fatty alcohol polyoxyethylene ether (MOA-3), stir, heat to 30°C, and dissolve 10g of fatty alcohol polyoxyethylene ether (MOA-9) , 1g phosphoric acid diester, 1g butyl acrylate, 1g carboxylate, 1g polyvinyl alcohol, 0.5g polyacrylamide, 0.5g xanthan gum and 30°C water (emulsified water) were slowly added dropwise to the round-necked flask until Emulsion phase inversion. Increase the rotation speed to 150r / min, and slowly pour in the remaining water. After stirring for 20 minutes, the rotation speed was reduced to 60r / min, and after cooling, the material was discharged to obtain the multifunctional surface optimizer YH-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com