Nanofiber reinforced polyimide aerogel material and preparation method thereof

A polyimide and aerogel technology, applied in the field of aerogel materials and their preparation, can solve problems such as low strength, and achieve the effects of enhanced mechanical strength, easy operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Using N,N-dimethylacetamide as a solvent, the solid content is prepared by condensation polymerization of 4,4'-diaminodiphenyl ether and terephthalic anhydride in an ice-water bath in an equimolar ratio 15% polyamic acid. The specific process is as follows: Dissolve 8.0096g of 4,4'-diaminodiphenyl ether in 95.57g of N,N-dimethylacetamide, add 8.8556g of pyromellitic dianhydride, and react in an ice-water bath for 5h. Then, 4.0476 g of triethylamine was added, and the reaction was continued for 5 h to prepare a water-soluble polyamic acid solution with a solid content of 15%. The prepared water-soluble polyamic acid is precipitated with deionized water, and then washed and freeze-dried to obtain a water-soluble polyamic acid prepolymer for use.

[0032] (2) Using N,N-dimethylacetamide as a solvent, the solid content is prepared by condensation polymerization of 4,4'-diaminodiphenyl ether and terephthalic anhydride in an ice-water bath in an equimolar ratio It is 15...

Embodiment 2

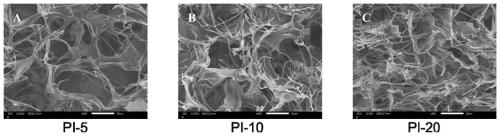

[0035] The difference between this example and Example 1 is that the mass of the short polyimide nanofibers in Example 1 is changed to 0.25g. That is, take 50mL of deionized water, 2.5g of polyamic acid prepolymer, and 2.5g of triethylamine, mix them evenly, and obtain a polyamic acid hydrogel after 24 hours of sol-gel process. Then add 0.25g of short polyimide nanofibers to the hydrogel, mix well and then freeze-dry and thermally imidize the sample to obtain a fiber-reinforced polyimide airgel, which is named PI-10 .

Embodiment 3

[0037]The difference between this example and Example 1 is that the mass of the short polyimide nanofibers in Example 1 is changed to 0.5 g. That is, take 50mL of deionized water, 2.5g of polyamic acid prepolymer, and 2.5g of triethylamine, mix them evenly, and obtain a polyamic acid hydrogel after 24 hours of sol-gel process. Then add 0.5g of polyimide nano-short fibers to the hydrogel, mix well, freeze-dry and heat imidize the sample to obtain fiber-reinforced polyimide airgel, and name it PI-20 .

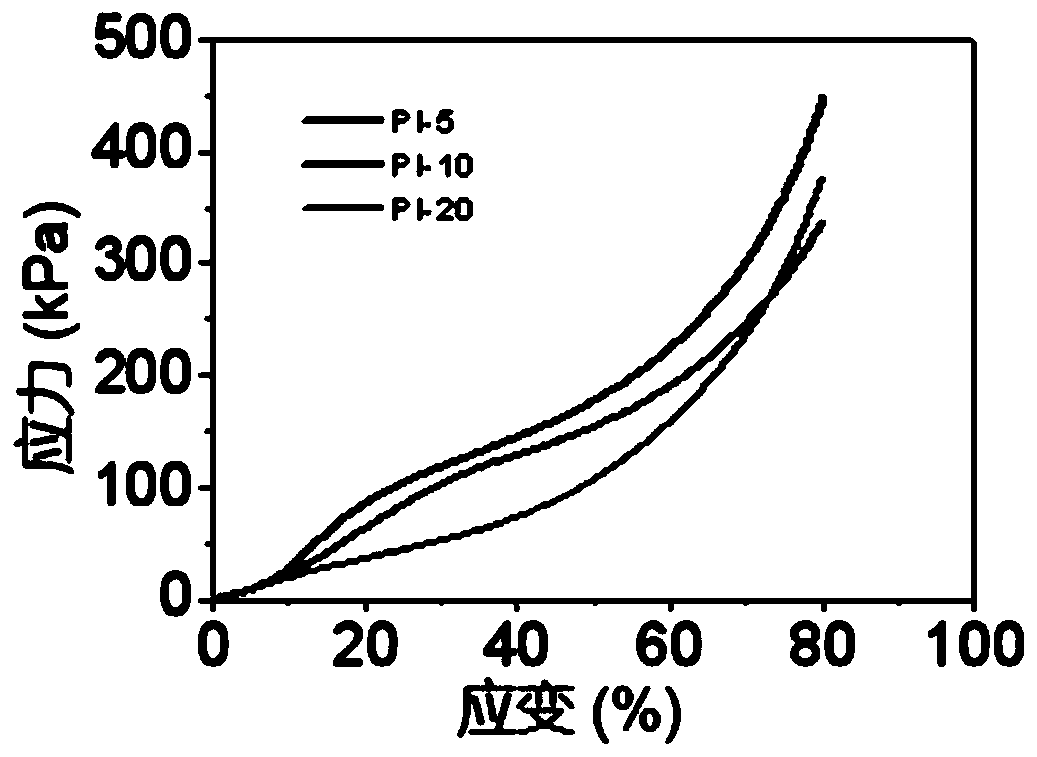

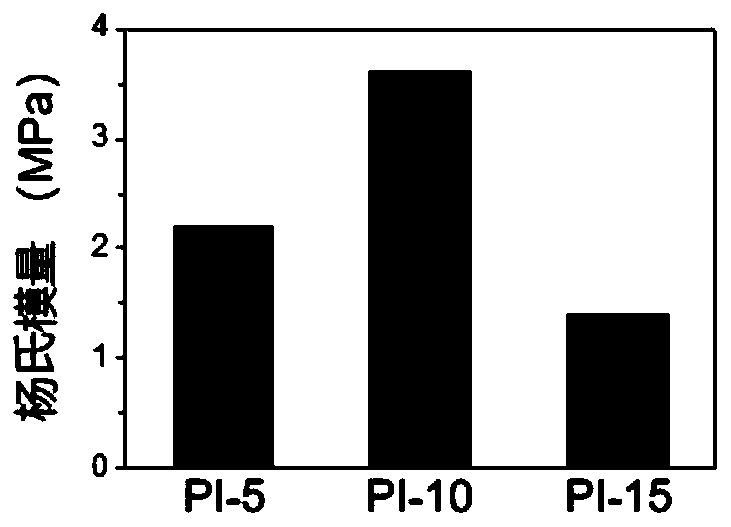

[0038] The stress-strain curves of nanofiber-reinforced polyimide airgel are as follows: figure 2 As shown, as the content of polyimide nano-short fibers increases, the maximum stress of the sample increases, and the curve does not shake significantly when the strain is 80%, indicating that it can still maintain structural integrity. The slope of the linear region in the curve also increases with the increase of the short fiber content, and the Young's modulus of the airgel in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com