Starch-base cooling material and application thereof

A starch-based, starch-based technology, applied in applications, smoker supplies, food science, etc., can solve the problems of not being able to achieve strong cooling, low filtration, etc., and achieve the effects of improving the sensory comfort of smoking, reducing retention, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

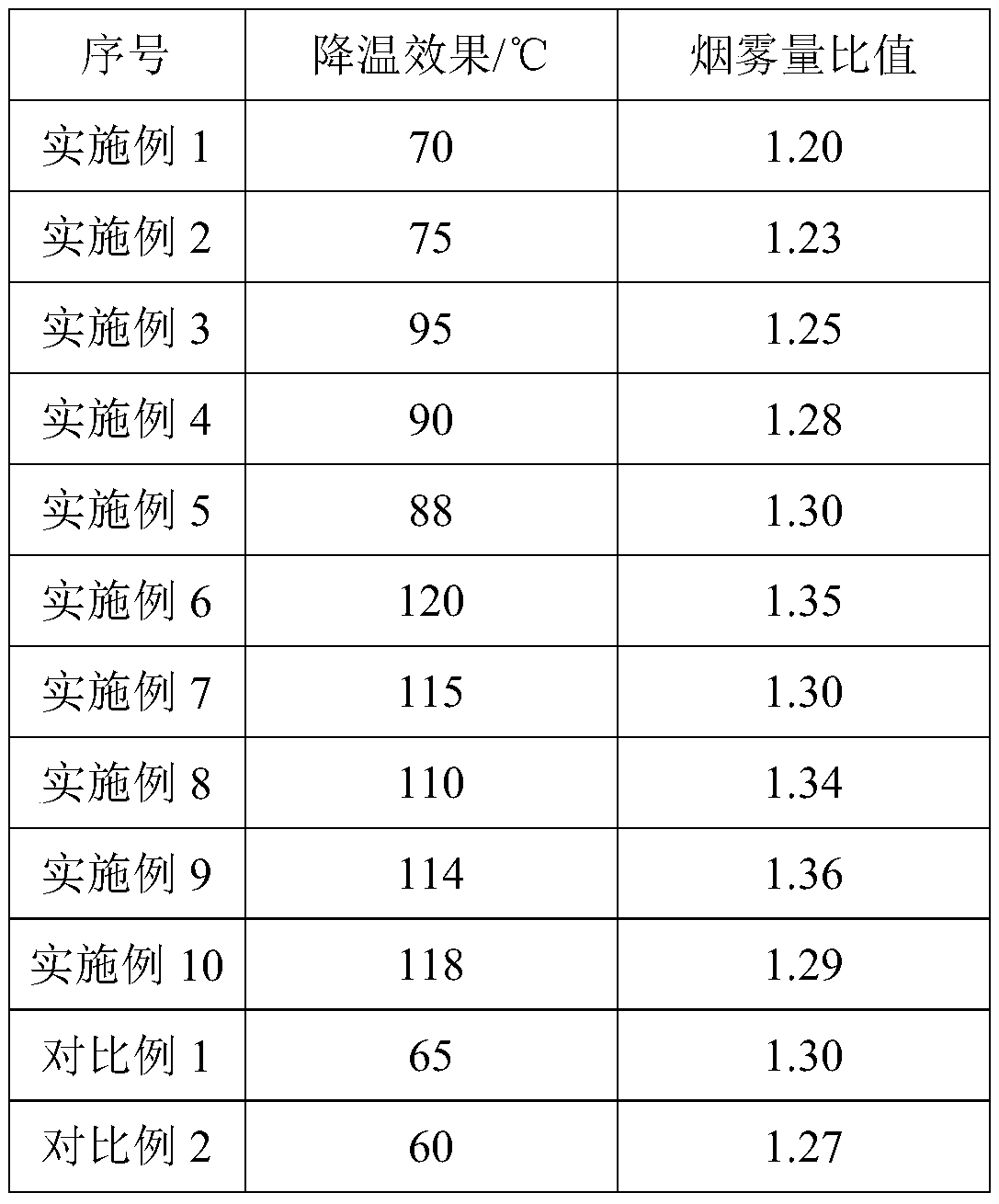

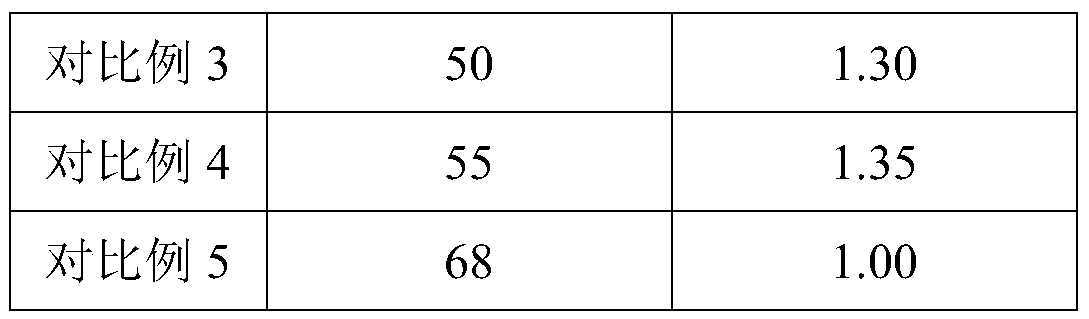

Examples

Embodiment 1

[0045] A starch-based cooling material. The starch-based cooling material is prepared from 5.0 parts of starch, 0.2 parts of a phase-change material, and 0.3 parts of a polyol, wherein the starch is cornstarch, the phase-change material is polylactic acid, and the polyol is glycerol.

[0046] Concrete preparation process is as follows:

[0047] 1) Material melting and mixing

[0048] 1) Heating and melting polylactic acid, four temperature zones control the temperature, zone 1-2 quickly heats up to melt, reducing the damage of molecular structure in the process; zone 2-3, heats up slightly, melts fully and does not decompose; zone 3- Zone 4, the melt state is stable;

[0049] 2) Add starch: Add in temperature control zone 3 and mix thoroughly;

[0050] 3) Adding polyols: adding in the temperature control zone four;

[0051] 2) Extrusion: Twin-screw extrusion

[0052] 3) Vacuum setting

[0053] Four) Cooling and shaping

[0054] 5) traction

[0055] 6) Cutting: fixed len...

Embodiment 2

[0057] A starch-based cooling material. The starch-based cooling material is prepared from 15.0 parts of starch, 5.0 parts of a phase-change material, and 3.0 parts of a polyol, wherein the starch is potato starch, the phase-change material is polylactic acid, and the polyol is glycerol.

[0058] Concrete preparation process is as follows:

[0059] 1) Material melting and mixing

[0060] 1) Heating and melting polylactic acid, four temperature zones control the temperature, zone 1-2 quickly heats up to melt, reducing the damage of molecular structure in the process; zone 2-3, heats up slightly, melts fully and does not decompose; zone 3- Zone 4, the melt state is stable;

[0061] 2) Add starch: Add in temperature control zone 3 and mix thoroughly;

[0062] 3) Adding polyols: adding in the temperature control zone four;

[0063] 2) Extrusion: Twin-screw extrusion

[0064] 3) Vacuum setting

[0065] Four) Cooling and shaping

[0066] 5) traction

[0067] 6) Cutting: fixed l...

Embodiment 3

[0069] A starch-based cooling material. The starch-based cooling material is prepared from 7.0 parts of starch, 3.0 parts of a phase-change material, and 2.0 parts of polyol, wherein the starch is potato starch, the phase-change material is polylactic acid, and the polyol is glycerol.

[0070] Concrete preparation process is as follows:

[0071] 1) Material melting and mixing

[0072] 1) Heating and melting polylactic acid, four temperature zones control the temperature, zone 1-2 quickly heats up to melt, reducing the damage of molecular structure in the process; zone 2-3, heats up slightly, melts fully and does not decompose; zone 3- Zone 4, the melt state is stable;

[0073] 2) Add starch: Add in temperature control zone 3 and mix thoroughly;

[0074] 3) Adding polyols: adding in the temperature control zone four;

[0075] 2) Extrusion: Twin-screw extrusion

[0076] 3) Vacuum setting

[0077] Four) Cooling and shaping

[0078] 5) traction

[0079] 6) Cutting: fixed le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com