Preparation method of high-tenacity graphene/PET compound film composition

A graphene and composite film technology, applied in flexible coverings, airbag layout, packaging, etc., can solve the problems of low toughness of PET film materials, poor barrier performance of PET film materials, high cost, etc., to achieve improved tensile strength and The effect of elongation at break, improvement of barrier properties, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

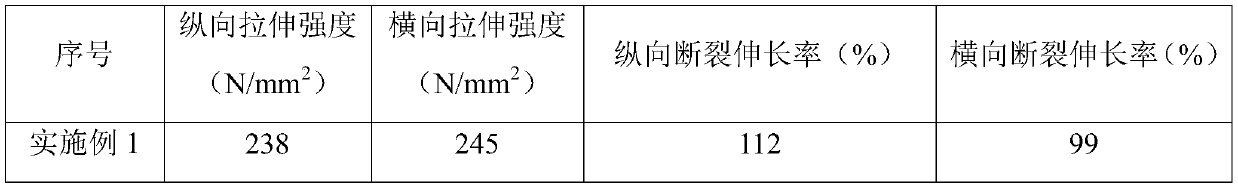

Embodiment 1

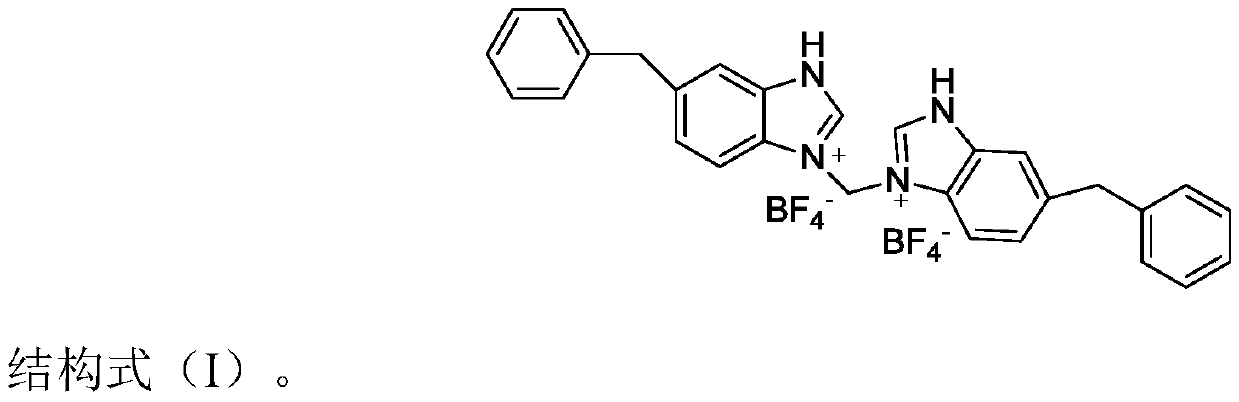

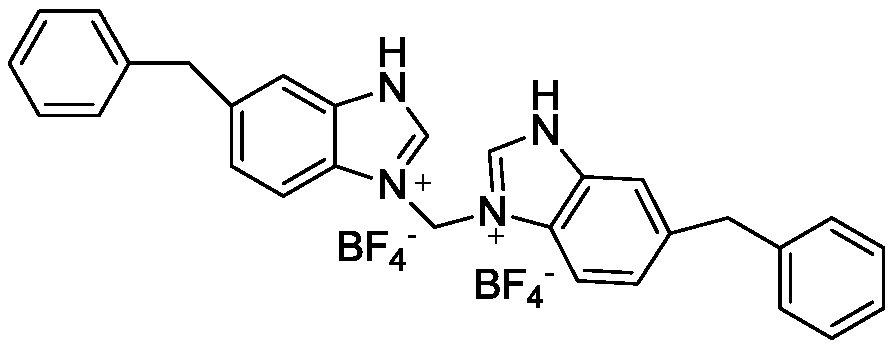

[0023] 65 parts by weight of PET, 8 parts by weight of epoxy polyether terminated with hydroxyl groups, 3 parts by weight of graphene, 7 parts by weight of nano-magnesium-aluminum hydrotalcite Mg-Al-LDHs, 7 parts by weight of nano-zinc-aluminum hydrotalcite Zn-Al-LDHs Parts, nano-SO 4 2- / ZrO 2 5 parts by weight of powder, 4 parts by weight of bisbenzylbenzimidazole ionic liquid surfactant, 0.5 parts by weight of anilinomethyltriethoxysilane, and 0.5 parts by weight of γ-aminopropyltrimethoxysilane, put into reaction In the container, stir for 15min at a rotation speed of 500r / min. Then the discharged material is transferred to a screw extruder, and the graphene / PET composite film composition is obtained through blending, melt extrusion, and parallel extrusion casting.

Embodiment 2

[0025] 64 parts by weight of PET, 9 parts by weight of epoxy polyether terminated with hydroxyl groups, 3.9 parts by weight of graphene, 16 parts by weight of nano zinc aluminum hydrotalcite Zn-Al-LDHs, nanometer SO 4 2- / ZrO 2 4 parts by weight of powder, 3 parts by weight of bisbenzylbenzimidazole ionic liquid surfactant, and 0.1 part by weight of anilinomethyltrimethoxysilane were put into the reactor, and stirred for 15 minutes at a rotation speed of 300 r / min. Then the discharged material is transferred to a screw extruder, and the graphene / PET composite film composition is obtained through blending, melt extrusion, and parallel extrusion casting.

Embodiment 3

[0027] 63 parts by weight of PET, 7 parts by weight of hydroxyl-terminated epoxy polyether, 5 parts by weight of graphene, 16.9 parts by weight of nano-zinc-aluminum hydrotalcite Zn-Al-LDHs, nano-SO 4 2- / ZrO 2 1 part by weight of powder, 7 parts by weight of bisbenzylbenzimidazole ionic liquid surfactant, and 0.1 part by weight of anilinomethyltrimethoxysilane were put into the reactor and stirred for 20 minutes at a rotation speed of 500 r / min. Then the discharged material is transferred to a screw extruder, and the graphene / PET composite film composition is obtained through blending, melt extrusion, and parallel extrusion casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com