High weather resistant powder coating and production process thereof

A powder coating, high weather-resistant technology, used in powder coatings, coatings, etc., can solve the problems of powder coatings incompetence, achieve excellent compatibility, reduce friction coefficient, and improve smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A high weather resistance powder coating, the components and their corresponding parts by weight are shown in Table 1. Among them, the fluorocarbon resin is the fluorocarbon resin sf-750h purchased from Beijing Huatong Rich; the titanium dioxide is the titanium dioxide R-699 purchased from Billions Group; the leveling agent is the leveling agent produced by Ningbo Nanhai Chemical Co., Ltd. The curing agent is triglycidyl isocyanurate (TGIC) purchased from Changzhou Niutang Chemical Factory Co., Ltd.; the surface treatment agent is wax powder 0602f purchased from Nanjing Tianshi New Material Technology Co., Ltd.; the brightening agent is BLC701B was purchased from Ningbo Nanhai Chemical Co., Ltd.; benzoin was benzoin 119-53-9 purchased from Shanghai Yuanye Biotechnology Co., Ltd.; the inorganic filler was precipitated barium sulfate BS80 purchased from Shanghai Yutong Chemical Technology Co., Ltd.

[0036] Silicone modified polyester resin is prepared through ...

Embodiment 2-5

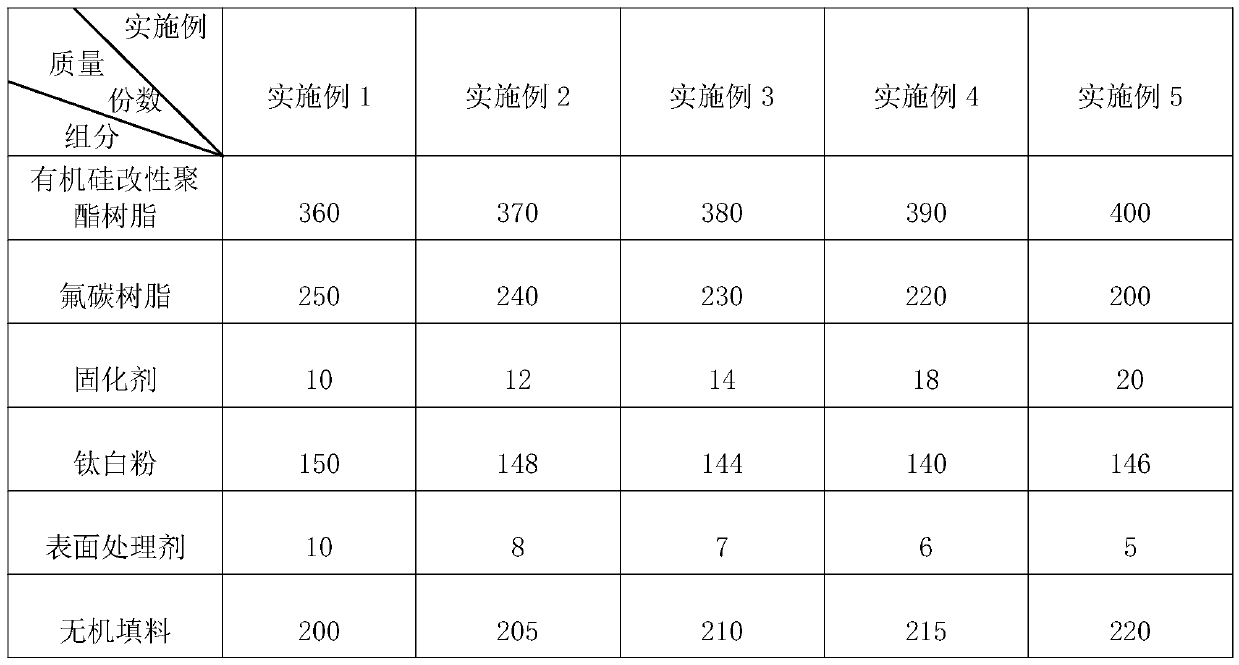

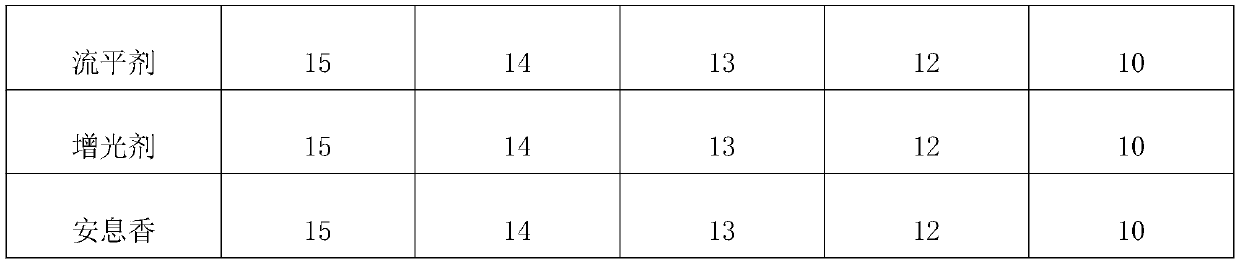

[0043] Example 2-5: A high weather resistance powder coating, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0044] Each component and parts by weight thereof in table 1 embodiment 1-5

[0045]

[0046]

Embodiment 6

[0047] Embodiment 6: A high-weather-resistant powder coating, which is different from Embodiment 1 in that the curing agent used is an imidazoline curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com