High-performance carbon nanotube/metal composite conductive fiber and preparation method thereof

A technology of carbon nanotube fibers and carbon nanotubes, which is applied in the field of material science, can solve problems such as limited effect, damage, and poor thermal stability of interface structures, and achieve the effects of improving effective strength, improving transmission efficiency, and high interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

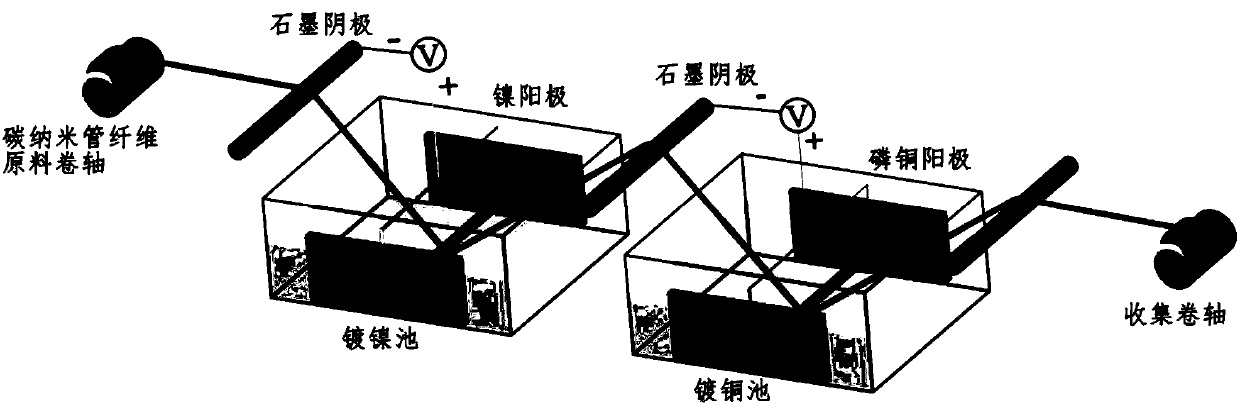

[0063] Another aspect of the embodiments of the present invention provides a method for preparing a high-performance carbon nanotube / metal composite conductive fiber, which includes:

[0064] Using continuous electroplating, a buffer layer is plated on the carbon nanotube fibers,

[0065] Plating a metal coating on the buffer layer, controlling the thickness of the coating by changing the collection speed, the collection speed is 5-35r / min;

[0066] Annealing the obtained metal coating-buffer layer-carbon nanotube fiber composite structure, so that the buffer metal forming the buffer layer continuously diffuses into the carbon nanotube fiber and the metal coating;

[0067] Using self-heating treatment technology, the obtained composite conductive fiber is energized, and the temperature generated by the electrothermal effect is used to induce the orientation of the metal grains in the metal coating, so that the (111) crystal plane of the metal grains and the carbon nanotube car...

Embodiment 1

[0086] see figure 1 and Figure 2c , the method for preparing high-performance carbon nanotube / metal composite conductive fiber in the present embodiment comprises:

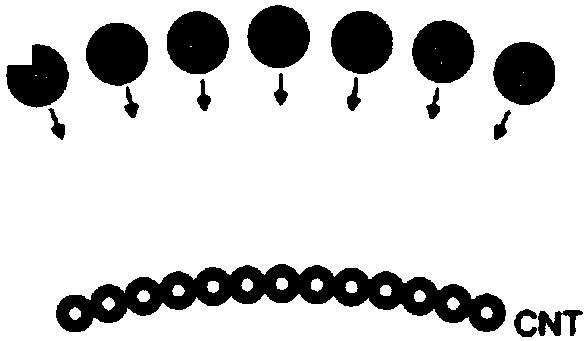

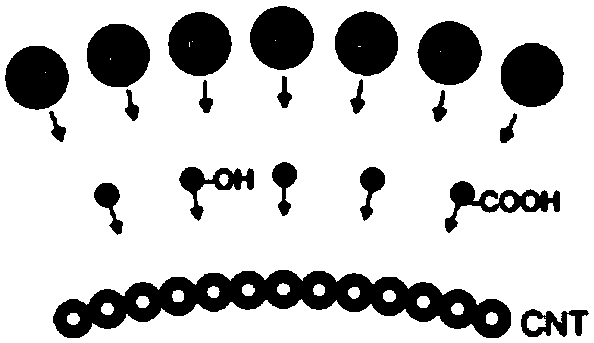

[0087] (1) Introduce a fast nickel plating step before the electroplating copper layer, and plate a uniform nano-scale nickel buffer layer on the surface of the carbon nanotube fiber, wherein the nickel plating parameters are: 10V constant voltage, current about 2mA, time 30s , the plating solution contains 120g / L nickel chloride (NiCl 2 ) and 200ml / L hydrochloric acid (HCl), the thickness of the resulting nickel buffer layer is 0.5 μm. Rapid nickel plating can introduce a large number of uniformly dispersed nano-nickel particles on the surface of carbon nanotube fibers, see Figure 3c As shown, these nickel particles will improve the subsequent copper plating process.

[0088] (2) Copper plating on the surface of the nickel buffer layer afterwards, wherein the copper plating parameters are: 5V pulse voltage,...

Embodiment 2

[0112] By changing the collection rate of the reel in Example 1 and keeping the electroplating formula and other electroplating parameters unchanged, composite conductive fibers with different thicknesses of coatings can be prepared. The relationship between collection speed and coating thickness can be found in Figure 19a As shown, and as the thickness of the coating changes, the density liquid of the obtained composite conductive fiber changes accordingly. For the specific relationship, see Figure 19b shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com