Composite paper for industrial exhaust gas adsorption of VOCs and manufacturing method of composite paper

A technology for industrial waste gas and composite paper, applied in the directions of synthetic cellulose/non-cellulose material pulp/paper, paper, papermaking, etc., can solve the problems of low corrugated strength, poor hardness and strength, increased production cost, etc. The effect of strength improvement, improved adhesion, hardness and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

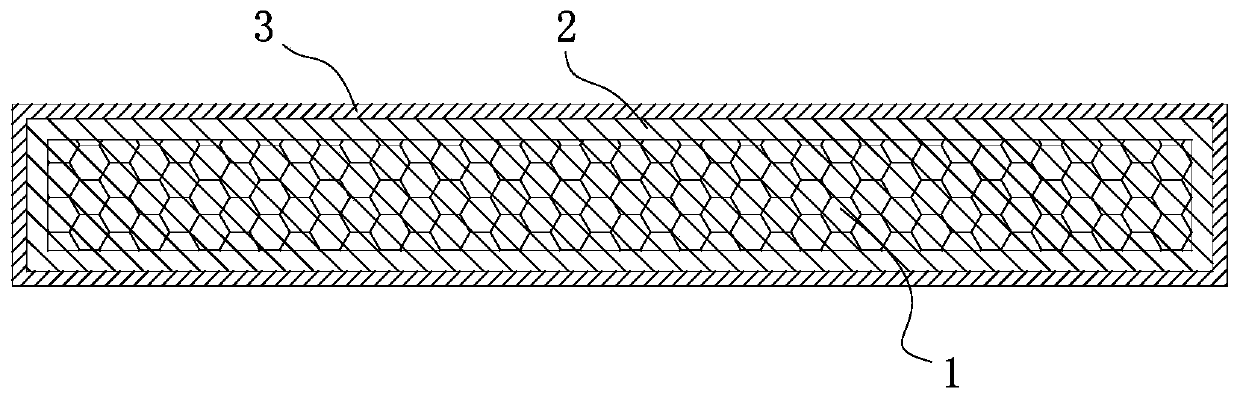

[0025] like figure 1 As shown, a composite paper for VOCs industrial waste gas adsorption includes a substrate carrier 1, the substrate carrier 1 is coated with a mixed slurry coating 2, and the mixed slurry of the mixed slurry coating 2 penetrates into the substrate carrier 1, the mixed slurry coating 2 and the substrate carrier 1 form an integrated composite paper inner layer, and the outer surface of the composite paper inner layer is coated with a molecular sieve coating 3.

[0026] The substrate carrier 1 has a thickness of 10-20 µm, and is made of glass fiber, the glass fiber has a specification of 15-25 g / m2, a fiber diameter of 5-20 µm, and a length of 200-5000 µm.

[0027] The above glass fiber material is used as the substrate carrier, which can form intersecting three-dimensional voids, which is conducive to the further diffusion of VOCs airflow, and at the same time can provide a three-dimensional distribution carrier for molecular sieves, which is conducive to imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com