Method for in-situ construction of defect active site in transition metal oxide catalyst

A transition metal, active site technology, applied in the field of electrocatalytic oxygen evolution, can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

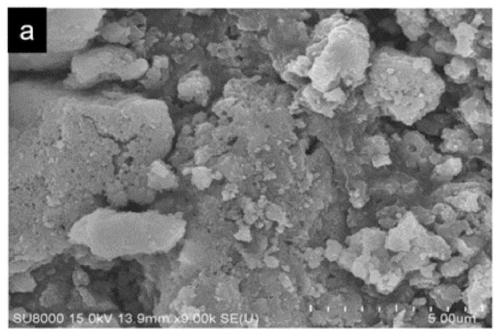

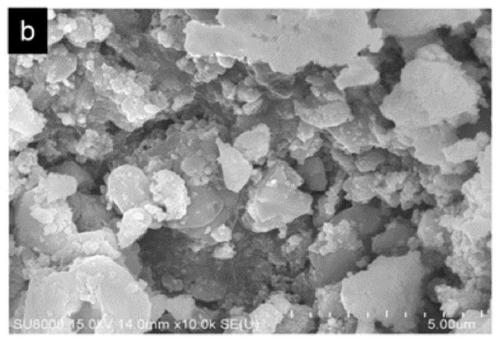

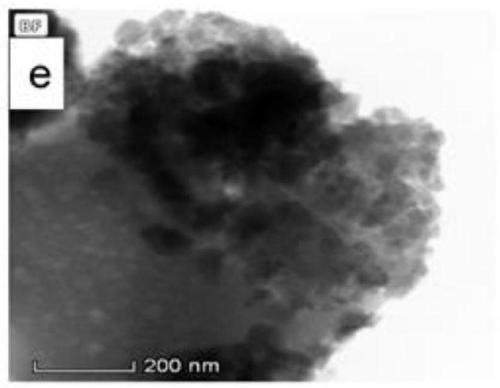

[0027] A specific embodiment of the present invention comprises the following experimental steps:

[0028] (1) Preparation of sulfur-containing manganese / cobalt mixed oxide precursor: 0.264mmol MnSO 4 ·H 2 O and 0.258mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 40 mL of DMF and 40 mL of acetone, and 0.8 mmol of 5-sulfonic isophthalic acid (5-SSIPA) was added for mixing and stirring.

[0029] Then it was placed in an autoclave and reacted at 160° C. for 4 hours; after that, it was kept in a high-speed centrifuge at a speed of 8000 r / min for 5 minutes to obtain a sulfur-containing manganese / cobalt mixed oxide precursor.

[0030] (2) Synthesis of sulfur-containing modified manganese / cobalt mixed oxide particles: the sulfur-containing manganese / cobalt mixed oxide precursor in step (1) was placed in a muffle furnace, and the temperature was raised to 500°C at 5°C / min. and keep it for 10 minutes; then cool to room temperature to obtain sulfur-containing modified manganese / cobal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com