Preparation of rhodium loaded porous siphonate carbon nitride photocatalyst, and hydrodechlorination catalytic reaction of parachlorophenol of rhodium loaded porous siphonate carbon nitride photocatalyst

A hydrodechlorination and catalytic reaction technology, applied in the preparation of organic compounds, catalysts for physical/chemical processes, and preparation of carbon-based compounds, etc., can solve problems such as incomplete oxidation, and achieve simple preparation methods, increased light radiation, chemical The effect of selective enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0028] The preparation method of the porous tubular carbon nitride Rh / PCN of loaded rhodium shown in the embodiment of the present invention may further comprise the steps:

[0029] 1) Add 10g of melamine into a porcelain crucible, heat it to 550°C in air at a heating rate of 5°C / min and keep it for 4h to obtain PCN.

[0030] 2) Ultrasonic disperse 0.5g of pure carbon nitride in the mixed solution of ethanol and water, add rhodium chloride into the mixed solution, stir at room temperature for 24 hours, add NaBH under vigorous stirring 4 solution, lasted overnight, the solution was centrifuged, washed with water and ethanol three times, and the obtained solid was vacuum-dried to obtain a rhodium-loaded porous tubular carbon nitride photocatalyst Rh / PCN. Simultaneously prepared without NaBH 4 Reduced catalyst, abbreviated as RhCl 3 / PCN.

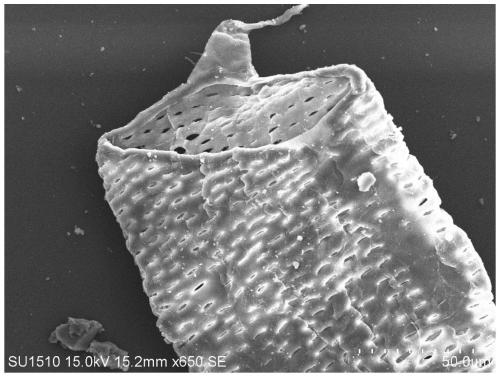

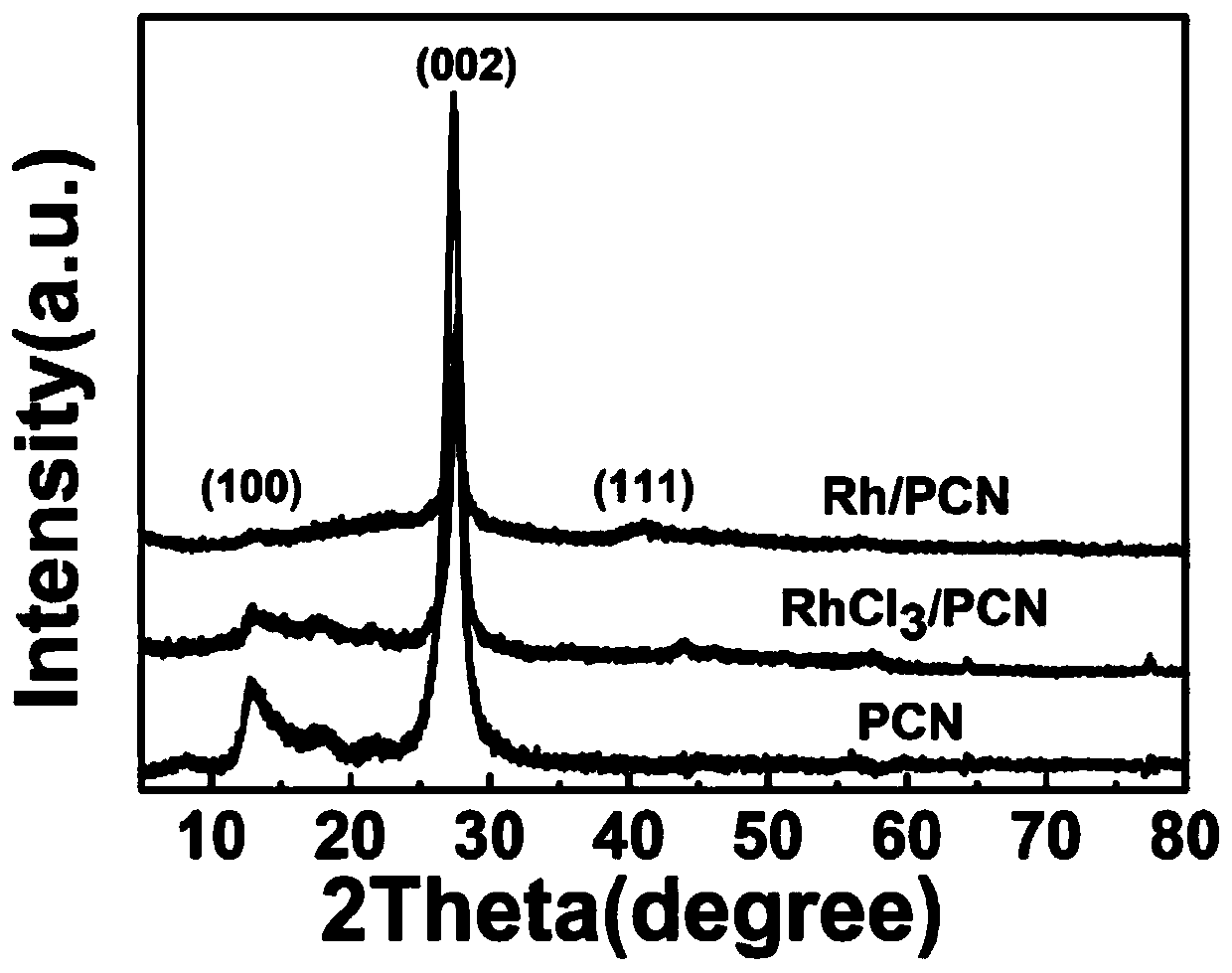

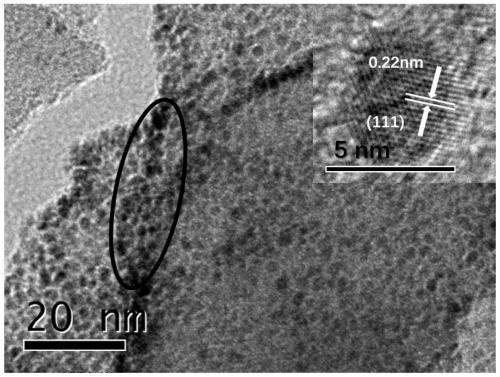

[0031] figure 1 is the NaBH in the above step (2) 4 The SEM image of the reduced Rh / PCN, from which it can be seen that the reduced Rh / P...

Embodiment example 2

[0035] Implementation Case 2 (response see Table 1, entry 4)

[0036] Place 5 mg of porous tubular carbon nitride supported rhodium catalyst Rh / PCN in a closed glass reaction tube, use hydrogen to replace the air in the tube several times, equip a balloon filled with hydrogen, add 5 ml of a mass concentration of 1.5 g / L 4-chlorophenol aqueous solution, The reaction temperature was controlled by a water bath at 30°C, and the reaction was performed for 30 min under the irradiation of a 30W red LED lamp. The conversion rate and product selectivity of p-chlorophenol were analyzed by GC and GC-MS. The conversion rate of 4-chlorophenol was 100.0%, and the selectivity of cyclohexanone and cyclohexanol was 52.2%.

[0037] Table 1. Condition optimization for photocatalytic 4-chlorophenol hydrodechlorination [a] .

[0038]

[0039] Implementation Case 2 (response see Table 1 entry 10)

[0040] Place 5 mg of porous tubular carbon nitride supported rhodium catalyst Rh / PCN in a close...

Embodiment example 3

[0041] Implementation Case 3 (response see Table 1 entry 11)

[0042] Place 5 mg of porous tubular carbon nitride supported rhodium catalyst Rh / PCN in a closed glass reaction tube, use hydrogen to replace the air in the tube several times, equip a balloon filled with hydrogen, add 5 ml of a mass concentration of 1.5 g / L 4-chlorophenol aqueous solution, The reaction temperature was controlled by a water bath at 30°C, and the conversion rate and product selectivity of p-chlorophenol were analyzed by GC and GC-MS after reacting for 30 min under sunlight irradiation. The conversion rate of 4-chlorophenol was 84.8%, and the selectivity of cyclohexanone and cyclohexanol was 36.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com