A kind of epoxy soybean oil rosin-cellulose-based polymer blend film and its preparation method and application

A cellulose-based, epoxy soybean technology, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effect of high strength and large EC molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the first step, add maleopimaric anhydride (MPA) and oxalyl chloride in a molar ratio of 1:1.3 into a reactor equipped with 40-80 mL (the amount added is for the purpose of completely dissolving the solid reactant) tetrahydrofuran (THF) as a solvent , carry out acid chlorination at a temperature of 50° C., and use a rotary evaporator to remove excess oxalyl chloride to obtain MPACl.

[0024] In the second step, MPACl was dissolved in THF according to 1g / 10mL, and was dropped into a solution dissolved with 12.3g EC (0.05mol), 6.5g DMAP (about 105% of EC) and THF (the EC added in the solution The ratio of the mass of THF to the volume of THF is 0.5 / mL), and the temperature is slowly raised to 40° C. for 5 hours. After the reaction, cool to room temperature, centrifuge the reaction mixture twice, pour the supernatant into excess distilled water (the amount of distilled water added is advisable to precipitate a large amount of product), and stir with a glass rod until co...

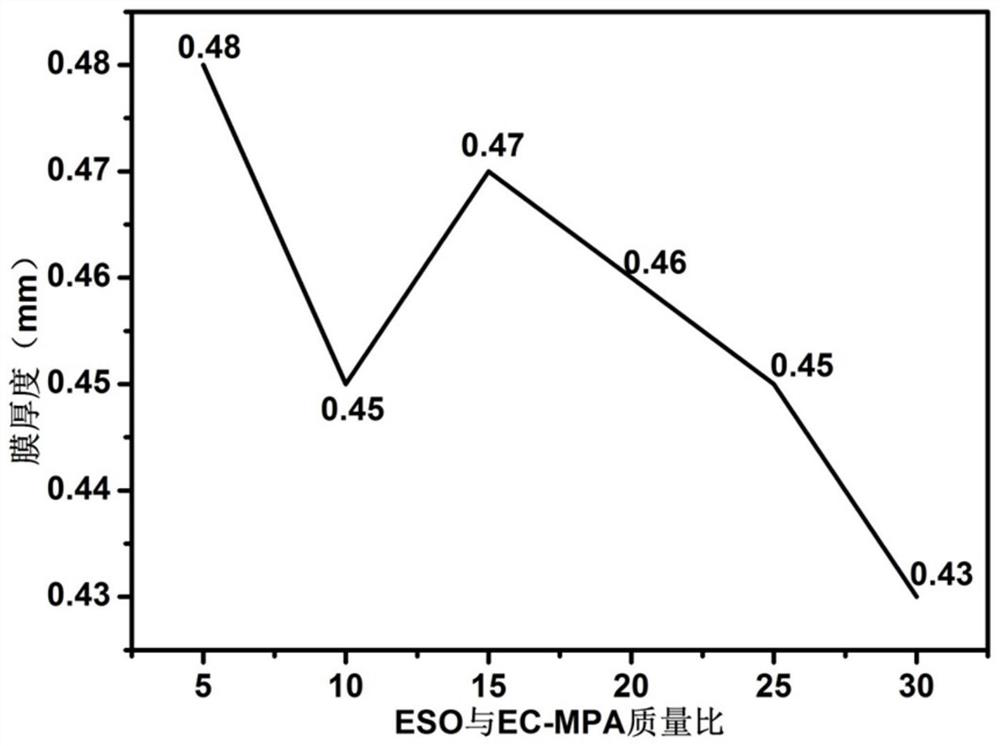

Embodiment 2

[0027] In the first step, add maleopimaric anhydride (MPA) and oxalyl chloride in a molar ratio of 1:1.3 into a reactor equipped with 40-80 mL (the amount added is for the purpose of completely dissolving the solid reactant) tetrahydrofuran (THF) as a solvent , carry out acid chlorination at a temperature of 50° C., and use a rotary evaporator to remove excess oxalyl chloride to obtain MPACl.

[0028] In the second step, MPACl was dissolved in THF according to 1g / 10mL, and was dropped into a solution dissolved with 12.3g EC (0.05mol), 6.5g DMAP (about 105% of EC) and THF (the EC added in the solution The ratio of the mass of THF to the volume of THF is 0.5 / mL), and the temperature is slowly raised to 40° C. for 5 hours. After the reaction, cool to room temperature, centrifuge the reaction mixture twice, pour the supernatant into excess distilled water (the amount of distilled water added is advisable to precipitate a large amount of product), and stir with a glass rod until co...

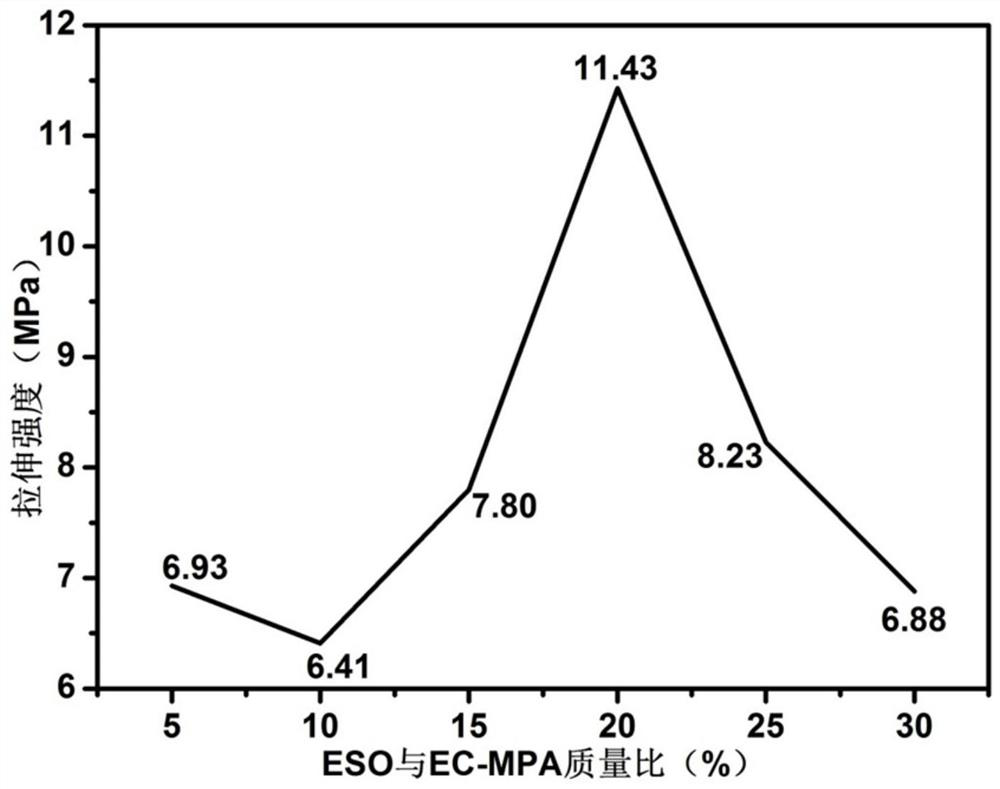

Embodiment 3

[0031]In the first step, add maleopimaric anhydride (MPA) and oxalyl chloride in a molar ratio of 1:1.3 into a reactor equipped with 40-80 mL (the amount added is for the purpose of completely dissolving the solid reactant) tetrahydrofuran (THF) as a solvent , carry out acid chlorination at a temperature of 50° C., and use a rotary evaporator to remove excess oxalyl chloride to obtain MPACl.

[0032] In the second step, MPACl was dissolved in THF according to 1g / 10mL, and was dropped into a solution dissolved with 12.3g EC (0.05mol), 6.5g DMAP (about 105% of EC) and THF (the EC added in the solution The ratio of the mass of THF to the volume of THF is 0.5 / mL), and the temperature is slowly raised to 40° C. for 5 hours. After the reaction, cool to room temperature, centrifuge the reaction mixture twice, pour the supernatant into excess distilled water (the amount of distilled water added is advisable to precipitate a large amount of product), and stir with a glass rod until com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com