Method for preparing SiC whiskers through interface reaction, and SiC whiskers

An interfacial reaction and whisker technology, which is applied in the field of preparation of high-performance ceramic materials, can solve the problems of small amount of SiC whiskers and long preparation time, and achieve fast heating speed, high energy utilization rate, and improved microstructure and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

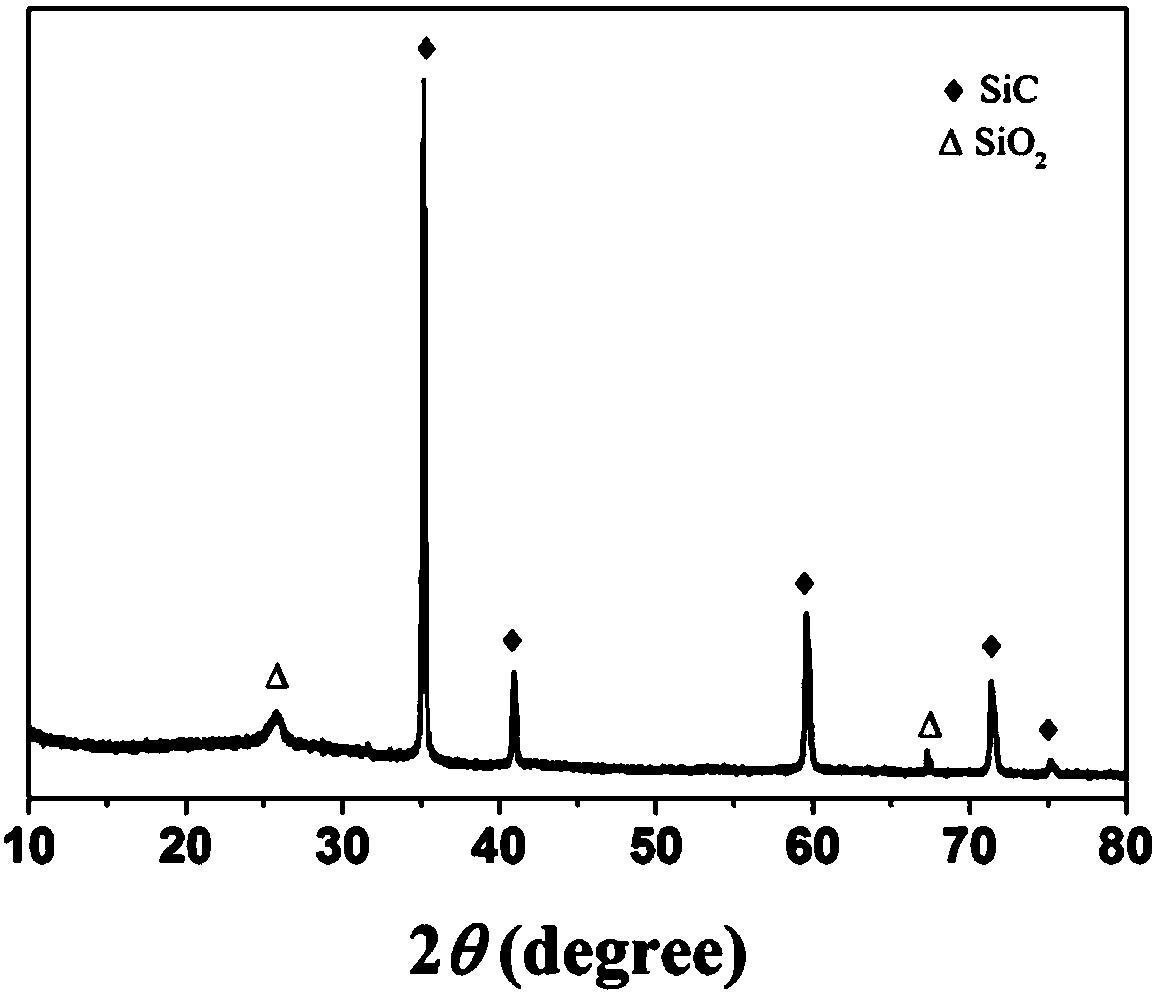

[0063] The method for preparing SiC whiskers by interfacial reaction in this embodiment comprises the following steps:

[0064] 1) Preparation of silica-carbon-boric acid precursor

[0065] Mix the three according to the volume ratio of tetraethyl orthosilicate, ethanol and distilled water at a ratio of 18:34:38, adjust the pH to 4 with boric acid, and stir at 80°C for 1 hour to obtain mixture A; Bioactive carbon with a particle size of less than 38 μm, stirred at 80°C for 3 hours, adjusted the pH to 8 with ammonia water, and continued to stir to obtain mixture B; filter mixture B, take the filter cake, and dry at 80°C to obtain silica-carbon- Boric acid precursor; wherein the molar ratio of carbon to silicon is 1.5:1, and the molar ratio of carbon to boric acid is 2:1; the amount of boric acid here refers to the amount of boric acid used for pH adjustment.

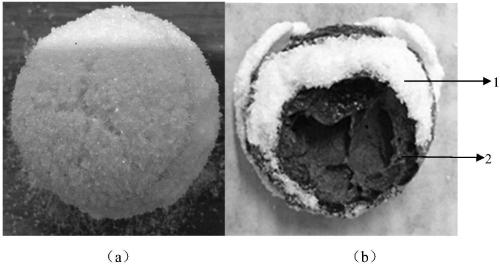

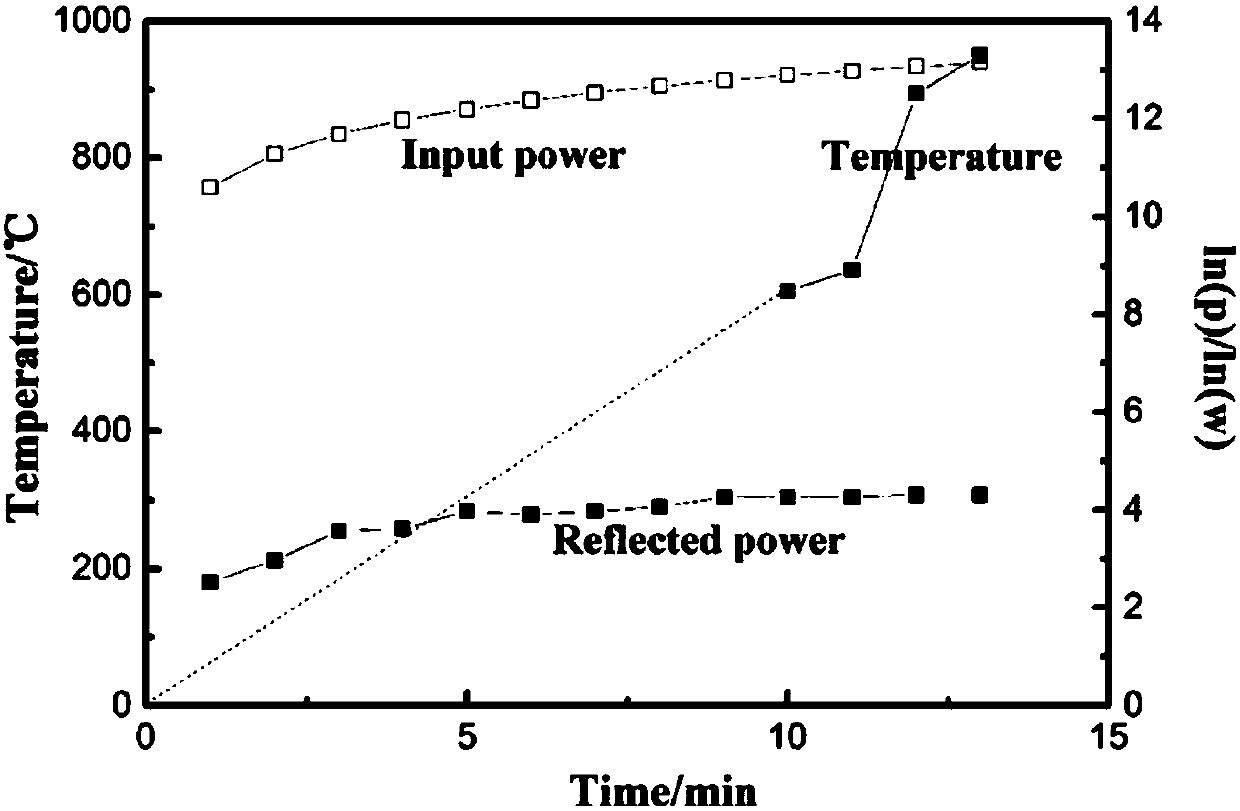

[0066] 2) Under the pressure of 3MPa, press the precursor obtained in step 1) into a cylindrical piece with a diameter...

Embodiment 2

[0069] The method for preparing SiC whiskers by interfacial reaction in this embodiment comprises the following steps:

[0070] 1) Preparation of silica-carbon precursor

[0071] Mix the three according to the volume ratio of ethyl orthosilicate, ethanol and distilled water as 20:36:40, adjust the pH to 4 with boric acid, and stir at 80°C for 2 hours to obtain mixture A; add coal particles to the mixture A, continue to stir for 4 hours, adjust the pH to 9 with ammonia water, and stir for 3 hours to obtain a mixture B; filter the mixture B and dry it at 100°C to obtain an amorphous silica-carbon-boric acid precursor; wherein the molar ratio of carbon to silicon is 2.5:1; the molar ratio of carbon to boric acid is 2.4:1;

[0072] 2) Under the pressure of 6MPa, press the precursor obtained in step 1) into a cylindrical piece with a diameter of 28mm and a thickness of 10mm, and then embed it in an alumina crucible with quartz sand, and place the crucible in a frequency of 2.45GHz...

Embodiment 3

[0075] The method for preparing SiC whiskers by interfacial reaction in this embodiment comprises the following steps:

[0076] 1) Preparation of silica-carbon-boric acid precursor

[0077] Mix the three according to the volume ratio of ethyl orthosilicate, ethanol and distilled water as 22:38:42, adjust the pH to 4 with boric acid, and stir at 80°C for 1.5h to obtain mixture A; take coal particles and add Mixture A, continue to stir for 4 hours, adjust the pH of the mixture to 9 with ammonia water, and obtain mixture B; filter mixture B and dry at 120°C to obtain an amorphous silica-carbon-boric acid precursor; wherein the moles of carbon and silicon The ratio is 3:1; the molar ratio of carbon to boric acid is 2.6:1;

[0078] 2) Under the pressure of 10MPa, press the precursor obtained in step 1) into a cylindrical piece with a diameter of 28mm and a thickness of 10mm, and then embed it in an alumina crucible with quartz sand, and place the crucible in a frequency of 2.45GHz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com