Method for improving capacity of cornstalk carbon-based super-electric material by using ammonium salt

A technology of corn stalk carbon and electric materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., achieves the effects of low temperature, simple operation and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The method for improving the capacity of corn stalk carbon-based superelectric materials by using ammonium salts comprises the following steps:

[0042] (1) Pretreatment: Cut 1g of straw into sections, add 0.1g of ammonium chloride, add 25ml of pure water to the container, then place the container in an autoclave and seal it, then conduct a hydrothermal reaction at 120°C, and then remove it by suction filtration Get a sample. Dry in a drying oven (60° C.) for 24 hours to obtain the product carbon;

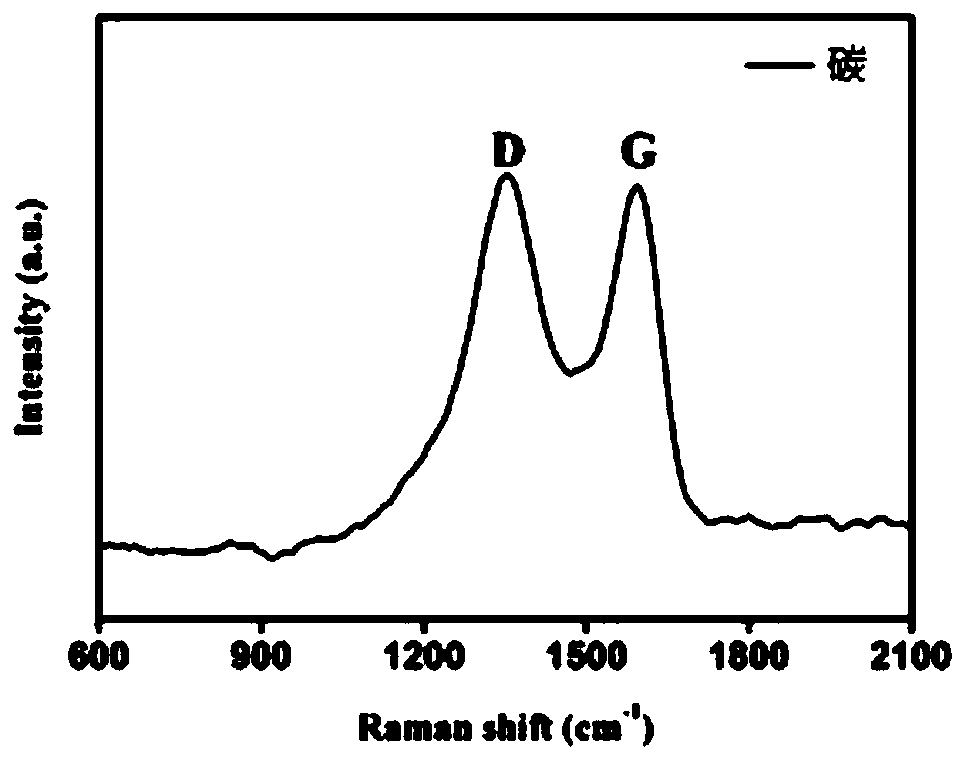

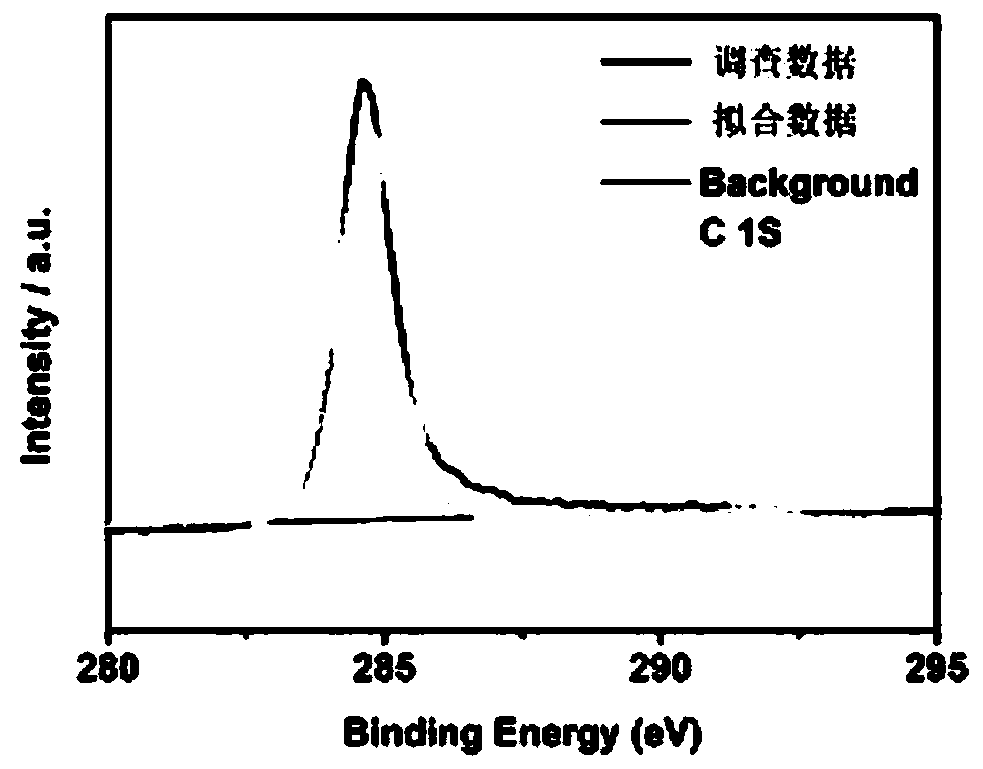

[0043] (2) Roasting and carbonization: put the product carbon in (1) directly in a tube furnace, under the protection of nitrogen atmosphere, the heating rate is 5°C / min, rise to 1000°C, hold for 2h, and carbonize;

[0044] (3) Coating: Weigh the carbonized material in (2) and mix and grind the polytetrafluoroethylene according to the commercial mass ratio (80:10:10), so that it is crushed into smaller particles, and the ground Add isopropanol to the medicine to dissolve i...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is that the quality of the stalk in step (1) is 5g, and the rest is the same as embodiment 1.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is that ammonium fluoride is added in step (1), and the rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com