Method for preparing lithium chloride by using four-compartment replacement reaction electrodialysis

A replacement reaction and electrodialysis technology, applied in electrodialysis, chemical instruments and methods, lithium halide, etc., can solve the problem of consuming a large amount of hydrochloric acid, and achieve the effect of simplifying the pretreatment process, reducing the degree of dependence, and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing lithium chloride, specifically comprising the following steps:

[0031] (1) Pulverizing and ball milling the lithium illuminite, and then calcining at 1000°C;

[0032] (2), ball milling the product of step (1) again, adding excess concentrated sulfuric acid, and carrying out sulfuric acid acidification under the condition of 250°C;

[0033] (3), the product of step (2) is dissolved, and an appropriate amount of Ca(OH) is added 2 , filter to remove impurities such as calcium ions, magnesium ions, iron ions, aluminum ions, etc., and the filtrate is mainly lithium sulfate;

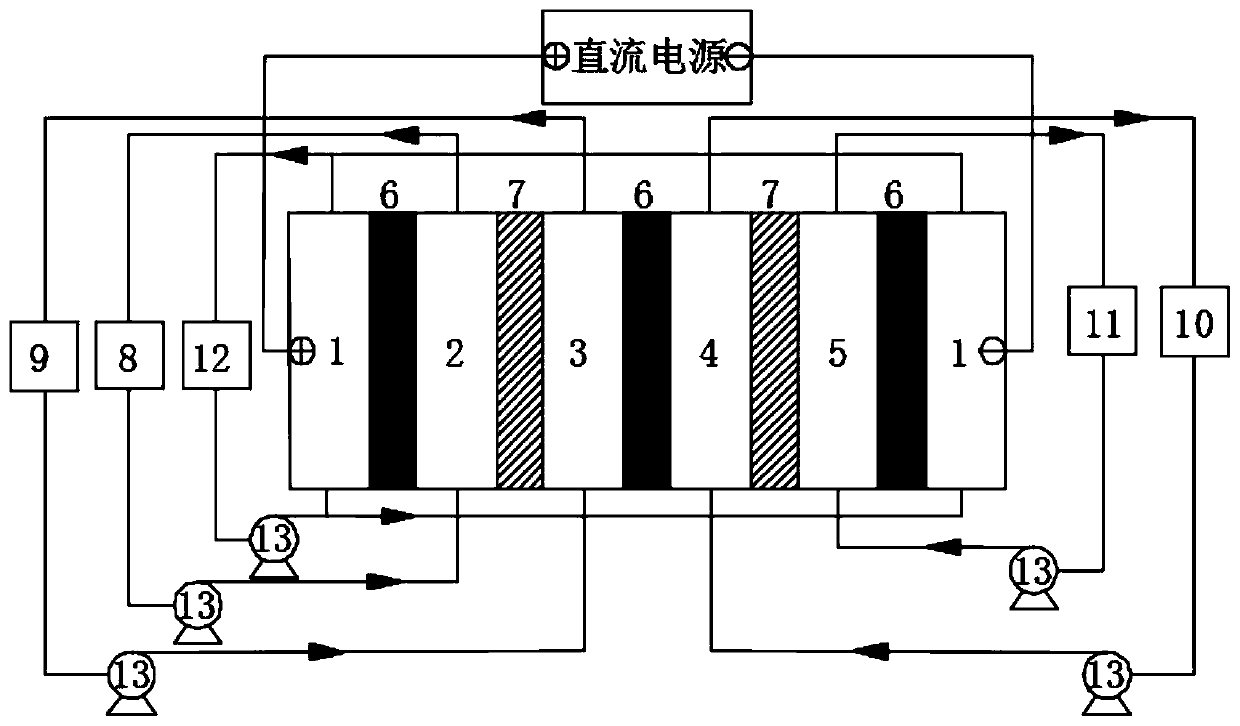

[0034] (4), the filtrate of step (3) is passed into the feed compartment II of the four-compartment displacement reaction electrodialysis device, and the sodium chloride solution is passed into the feed compartment IV, and under the action of the electric field force, the feed compartment Lithium ions in compartment II and chloride ions in feed compartment IV pass through the c...

Embodiment 2

[0036] A method for preparing lithium chloride, specifically comprising the following steps:

[0037] (1), first evaporate and concentrate the salt lake brine in the evaporation pond;

[0038] (2), step (1) is concentrated to a certain rate of solution, and calcium hydroxide is added, filtered, and impurities such as calcium and magnesium ions are removed;

[0039] (3), sodium carbonate is added in the filtrate of step (2) again, and reaction generates lithium carbonate and precipitates out, and some soluble impurities in the solution can be removed in the process;

[0040] (4), lithium carbonate that step (3) is obtained is dissolved, then pass into the feeding compartment II of the four-compartment displacement reaction electrodialysis device, and the sodium chloride solution is passed into the feeding compartment IV, under the force of the electric field Under the action, the lithium ions in the feed compartment II and the chloride ions in the feed compartment IV pass thro...

Embodiment 3

[0042] A kind of method for preparing lithium chloride in this embodiment, steps (1)-(3) are identical with embodiment 2, and different steps are specifically:

[0043] (4), the Lithium Retard that step (3) is obtained is added in water, feeds carbon dioxide gas, and Lithium Retard is carbonized and generates Lithium Carbonate; Then feeds into the feeding compartment II of the four-compartment displacement reaction electrodialysis device, sodium chloride The solution passes into the feed compartment IV, and under the action of the electric field force, the lithium ions in the feed compartment II and the chloride ions in the feed compartment IV pass through the cation exchange membrane and the anion exchange membrane respectively, and enter the product compartment Lithium chloride solution is obtained in III, bicarbonate ions in feed compartment II and sodium ions in feed compartment IV pass through anion exchange membrane and cation exchange membrane respectively, and sodium bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com