Method for preparing anti-oxidation antibacterial membrane with cinnamon essential oil Pickering emulsion

A technology of Pickering emulsion and cinnamon essential oil, which is applied in the field of preparation of anti-oxidation and antibacterial film, can solve the problems of short antibacterial film time, achieve good biocompatibility and stability, good mechanical properties, and relieve environmental pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

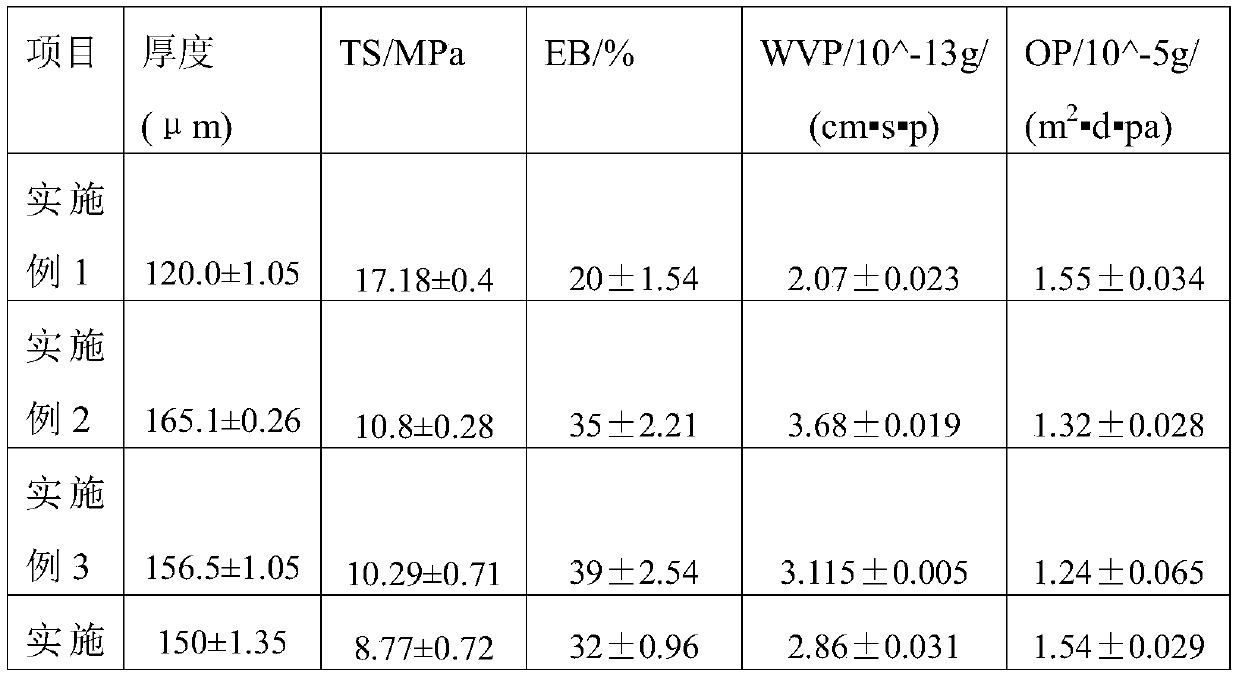

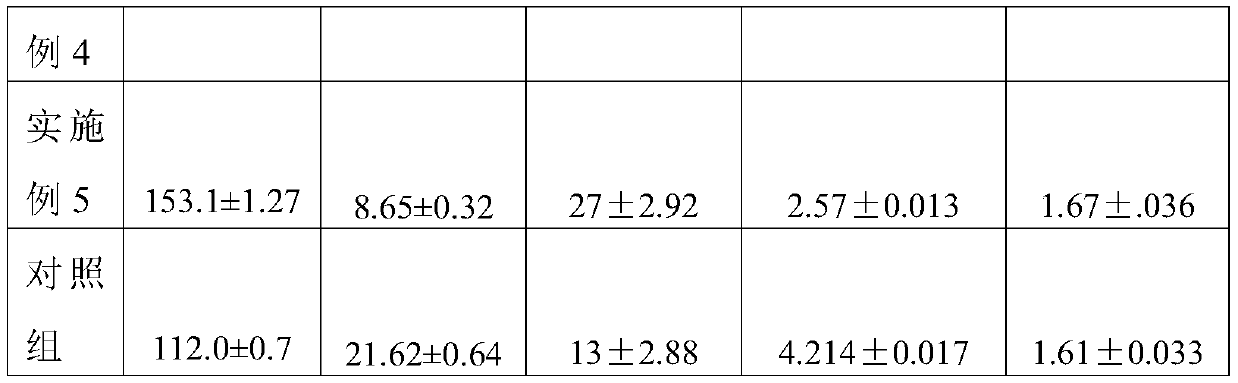

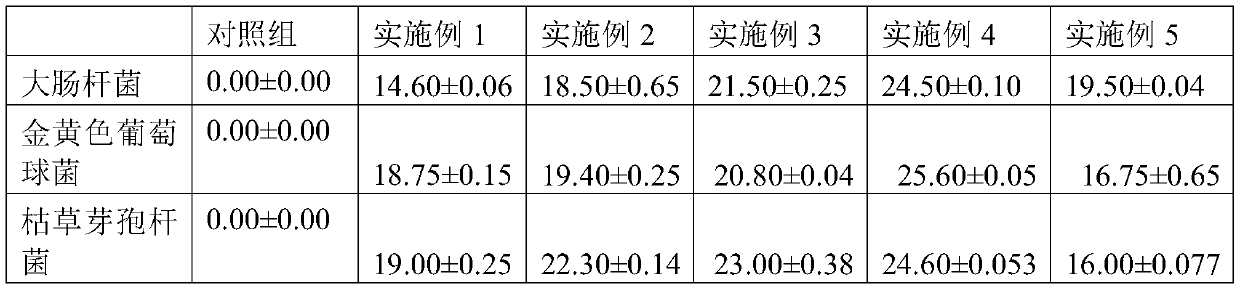

Examples

Embodiment 1

[0030] Step 1: Preparation of Pickering Emulsion

[0031] (1) Dissolve 5g of octenyl succinic acid starch in 50ml of water, stir evenly, and fully hydrate. 1.5 g of cinnamon essential oil was ultrasonically mixed with 1.5 g of corn germ oil.

[0032] (2) Add the mixed corn oil and cinnamon essential oil into the starch dispersion, and disperse with a homogenizer for 3 minutes at a speed of 13000r / min, each time for 40s with an interval of 20s.

[0033] Step 2: Preparation of Pickering emulsion film

[0034] (1) Weigh 3g of modified starch, moisten the sample with a small amount of distilled water, add 100mL of water to make a starch particle dispersion, after hydration, gelatinize in a water bath at 95°C for 30min, add 0.6g after gelatinization Sodium alginate, add 0.8g glycerin and stir for 12min, vacuum degassing for 30min, to form octenyl succinic acid starch film liquid.

[0035] (2) Get 20ml Pickering emulsion and step 2 (1) 100ml octenyl succinic acid starch film liqu...

Embodiment 2

[0038] Step 1: Preparation of Pickering Emulsion

[0039] (1) Dissolve 10g of octenyl succinic acid starch in 50ml of water, stir evenly, and fully hydrate. 3.6g of cinnamon essential oil was ultrasonically mixed with 2.4g of corn germ oil.

[0040] (2) Add the mixed corn oil and cinnamon essential oil into the starch dispersion, and disperse with a homogenizer for 3 minutes at a speed of 13000r / min, each time for 40s with an interval of 20s.

[0041] Step 2: Preparation of Pickering emulsion film

[0042] (1) Weigh 4g of modified starch, first wet the sample with a small amount of distilled water, add 100mL of water to make a starch particle dispersion, after hydration, gelatinize in a water bath at 95 degrees for 30min, add 1.2g after gelatinization Sodium alginate, 1.6g of glycerin was added and stirred for 12min, and vacuum degassed for 30min to form octenyl succinic acid starch film liquid.

[0043] (2) Get 20ml Pickering emulsion and step 2 (1) 100ml octenyl succinic ...

Embodiment 3

[0046] Step 1: Preparation of Pickering Emulsion

[0047] (1) Dissolve 15g of octenyl succinic acid starch in 50ml of water, stir evenly, and fully hydrate. 6.3 g of cinnamon essential oil was ultrasonically mixed with 2.7 g of corn germ oil.

[0048] (2) Add the mixed corn oil and cinnamon essential oil into the starch dispersion, and disperse with a homogenizer for 3 minutes at a speed of 13000r / min, each time for 40s with an interval of 20s.

[0049] Step 2: Preparation of Pickering emulsion film

[0050] (1) Weigh 5g of modified starch, moisten the sample with a small amount of distilled water, add 100mL of water to prepare a starch particle dispersion, after hydration, gelatinize in a water bath at 95 degrees for 30min, and add 1.25g after gelatinization Sodium alginate, add 1.75g glycerin and stir for 12min, vacuum degassing for 30min to form octenyl succinic acid starch film liquid.

[0051] (2) Get 20ml Pickering emulsion and step 2 (1) 100ml octenyl succinic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com