Ultrahigh-melt-index polylactic acid resin, and preparation method and applications thereof

A technology of polylactic acid resin and melt index, which is applied in the field of polylactic acid resin and its preparation, can solve the problems of low melt index, long production cycle, and cumbersome process, and achieve the effects of short production cycle, guaranteed processing performance, and simple preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

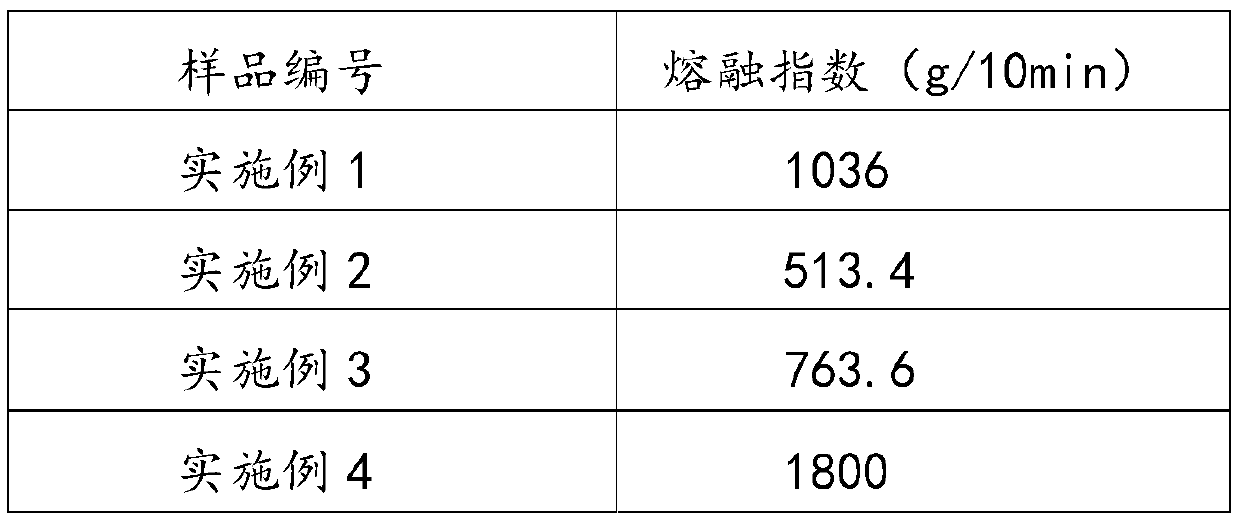

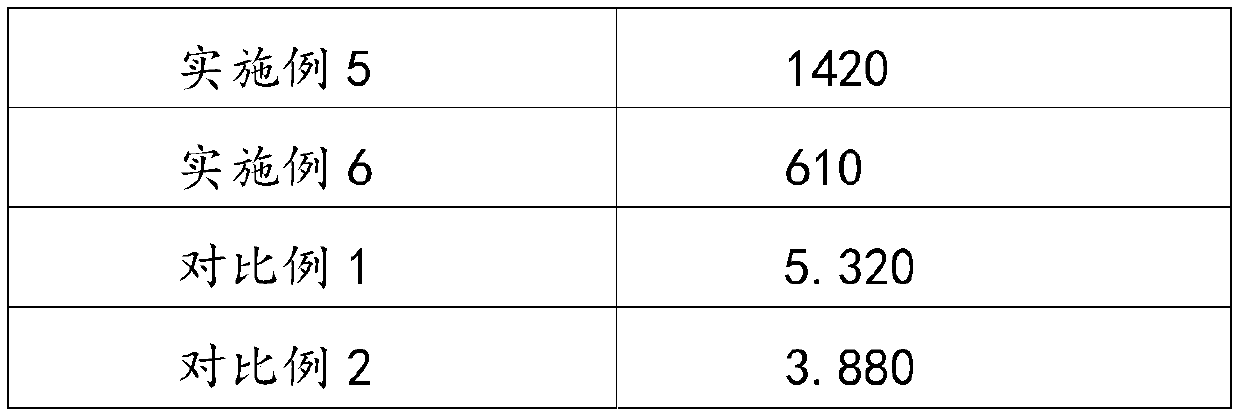

Examples

preparation example Construction

[0034] The embodiment of the present invention also provides a preparation method of ultra-high melt index polylactic acid resin, comprising the following steps:

[0035] (1) Catalyst, initiator, antioxidant are dissolved or dispersed in organic solvent, after mixing uniformly, obtain solution M, wherein catalyst concentration is 0.06-6.02g / mL, initiator concentration is 0-3.01g / mL, Antioxidant concentration is 0.6-6.02g / mL;

[0036] (2) Add solution M to polylactic acid, add 1.67mL solution M per kilogram of polylactic acid, after mixing evenly, carry out reactive extrusion on a twin-screw extruder, and the product is water-cooled and granulated to obtain ultra-high melt index polylactic acid resin.

[0037] In the above-mentioned examples, the catalyst, initiator, and antioxidant are configured in the form of a solution, and then mixed with polylactic acid resin, so that low-level additives can be uniformly dispersed in the solution and mixed with polylactic acid. The selec...

Embodiment 1

[0044] Disperse and dissolve 5 g of the catalyst stannous octoate, 5 g of the initiator dicumyl peroxide, 10 g of hindered phenolic antioxidant 1010, and 10 g of phosphite antioxidant 168 into 16.7 mL of dichloromethane to prepare a solution.

[0045] Use 10kg of polylactic acid resin with the brand name 6252D produced by NatureWorks as the matrix, add the above solution to it, mix evenly, and carry out reactive extrusion on a twin-screw extruder with φ35mm×2 and L / D=44 at 160-190°C Go out granulation, screw speed 300rpm. The extrudate is cooled and pelletized to obtain the final product.

Embodiment 2

[0047] Disperse and dissolve 20 g of catalyst tetrabutyl titanate, 3 g of initiator di-tert-butyl peroxide, 10 g of antioxidant 1010, and 15 g of antioxidant 168 into 16.7 mL of chloroform to prepare a solution.

[0048] Use 10kg of polylactic acid resin with the brand name 6252D produced by NatureWorks as the matrix, add the above solution to it, mix evenly, and carry out reactive extrusion on a twin-screw extruder with φ35mm×2 and L / D=44 at 180-200°C. Go out granulation, screw speed 200rpm. The extrudate is cooled and pelletized to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com