Road coating for purifying automotive tail gas and preparation method of coating

A technology for automobile exhaust and roads, applied in chemical instruments and methods, separation methods, epoxy resin coatings, etc., can solve problems such as large pollution and unsatisfactory photocatalyst loading effect, and achieve high production efficiency, green and pollution-free process, The effect of firm load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

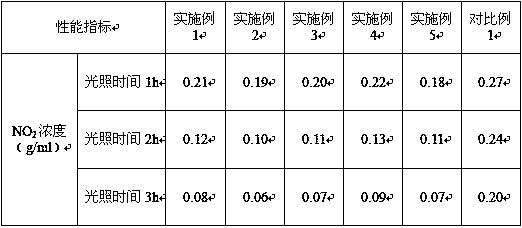

Examples

Embodiment 1

[0028] (1) Add titanium dioxide and nano-glass powder with an average particle size of 300nm to the diatomite powder, and mix evenly to obtain a mixed powder; the mass of titanium dioxide is 48% of the diatomite powder; the mass of nano-glass powder is the mass of titanium dioxide 5%. ;

[0029] (2) In the presence of protective gas, the mixed powder obtained in step (1) is laser welded by laser scanning technology, so that the glass powder is slightly fused and interconnected with the surface of nano-titanium dioxide, and is firmly combined with the diatomite carrier to obtain Diatomite welding is loaded with nano-titanium dioxide; the protective gas is nitrogen; the laser welding adopts carbon dioxide continuous laser welding, the laser power is 15mW, and the welding time is 700ns;

[0030](3) First mix water, wollastonite powder, limestone, methyl cellulose, water-based epoxy resin glue, bentonite, dispersant, and defoamer evenly, and then add the diatomite welding-loaded ...

Embodiment 2

[0032] (1) Add titanium dioxide and nano-glass powder with an average particle size of 300nm to the diatomite powder, and mix evenly to obtain a mixed powder; the mass of titanium dioxide is 45% of the diatomite powder; the mass of nano-glass powder is the mass of titanium dioxide 5% of

[0033] (2) In the presence of protective gas, the mixed powder obtained in step (1) is laser welded by laser scanning technology, so that the glass powder is slightly fused and interconnected with the surface of nano-titanium dioxide, and is firmly combined with the diatomite carrier to obtain Diatomite welding loaded nano-titanium dioxide; protective gas is argon; laser welding adopts carbon dioxide continuous laser welding, laser power 15mW, welding time 1300ns;

[0034] (3) First mix water, wollastonite powder, limestone, methyl cellulose, water-based epoxy resin glue, bentonite, dispersant, and defoamer evenly, and then add the diatomite welding-loaded nano-titanium dioxide obtained in st...

Embodiment 3

[0036] (1) Add titanium dioxide and nano-glass powder with an average particle size of 400nm to the diatomite powder, and mix evenly to obtain a mixed powder; the mass of titanium dioxide is 55% of the diatomite powder; the mass of nano-glass powder is the mass of titanium dioxide 5% of

[0037] (2) In the presence of protective gas, the mixed powder obtained in step (1) is laser welded by laser scanning technology, so that the glass powder is slightly fused and interconnected with the surface of nano-titanium dioxide, and is firmly combined with the diatomite carrier to obtain Diatomite welding loaded nano-titanium dioxide; protective gas is helium; laser welding adopts carbon dioxide continuous laser welding, laser power 30mW, welding time 500ns;

[0038] (3) First mix water, wollastonite powder, limestone, methyl cellulose, water-based epoxy resin glue, bentonite, dispersant, and defoamer evenly, and then add the diatomite welding-loaded nano-titanium dioxide obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com