Preparation method of manganese cobalt oxide with porous spherical hollow structure and application thereof

A porous spherical, oxide technology, applied in the direction of structural parts, fuel cell type half cells and primary cell type half cells, electrical components, etc., can solve many influencing factors, difficult to adapt to industrial needs, poor controllability, etc. problems, to achieve the effect of simple equipment, easy large-scale synthesis, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

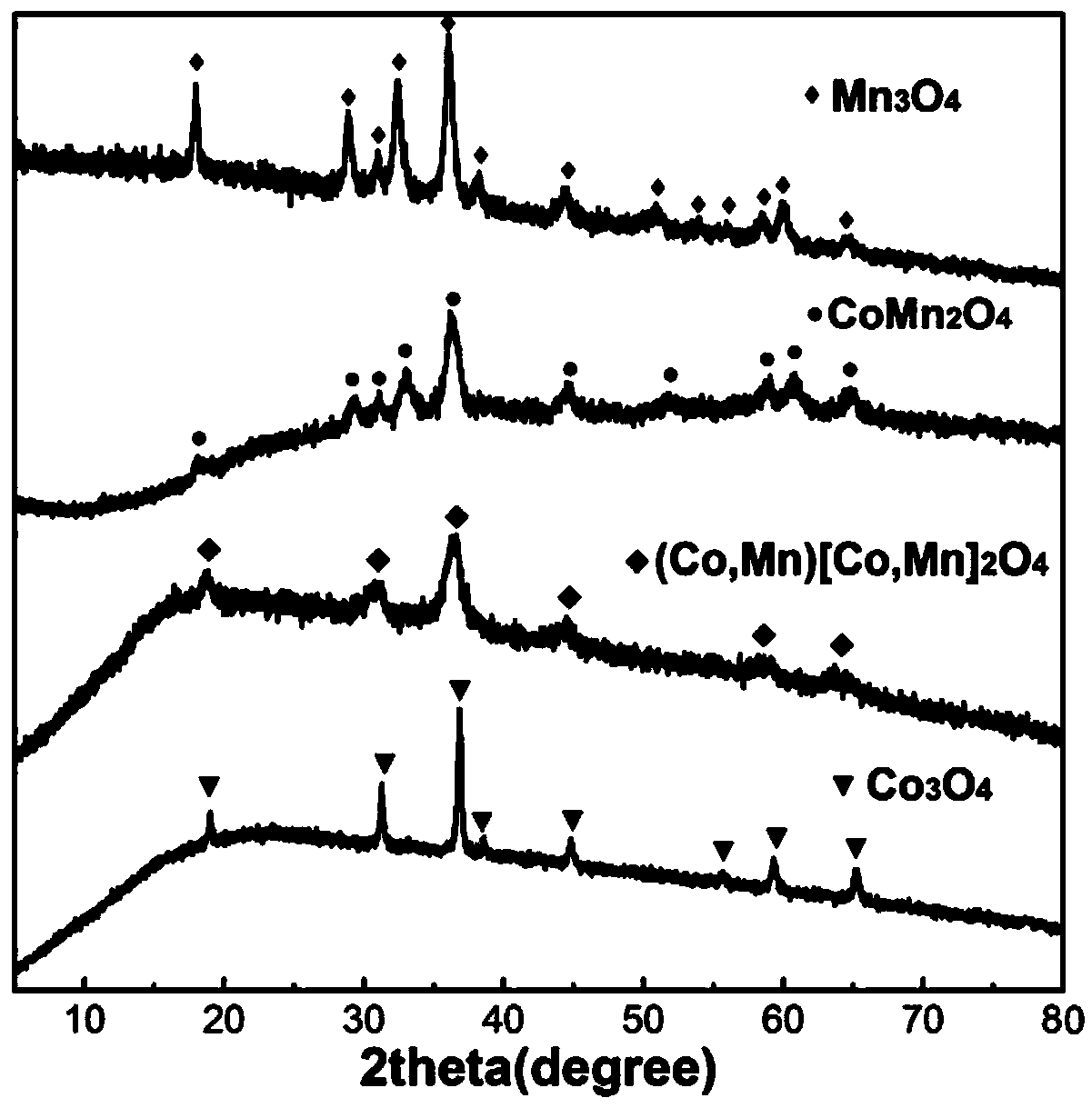

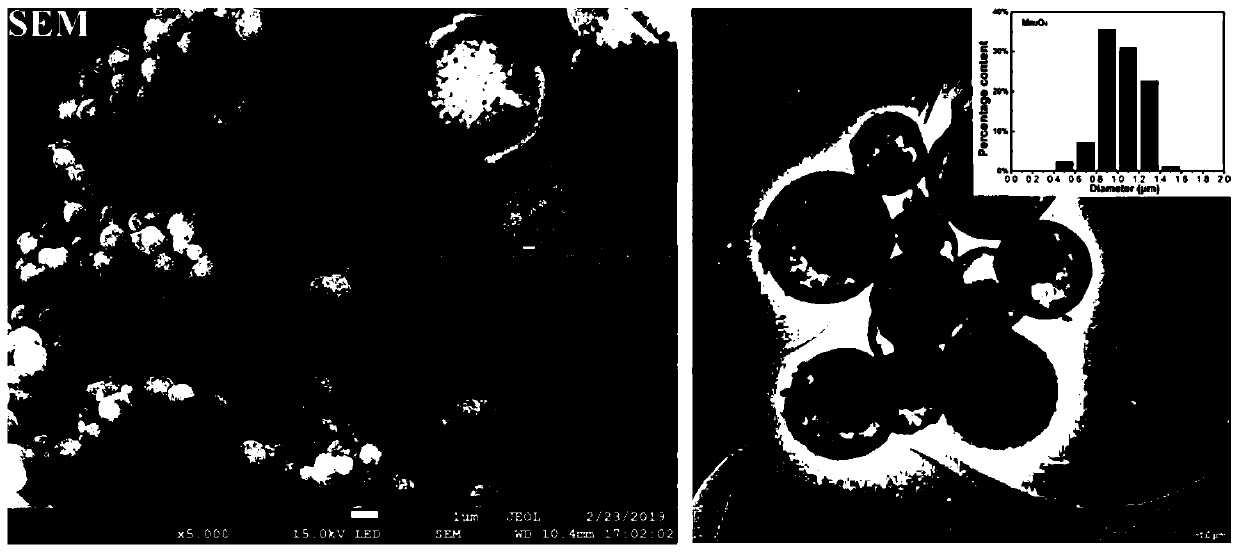

[0038] At room temperature, mix 30ml of ethylene glycol with 20ml of anhydrous methanol, and stir for 10min to obtain a homogeneous solution. Weigh 2 mmol of manganese acetate and add to the above solution, and stir at room temperature for 24 h to obtain a dark brown mixed solution. The manganese acetate solution was dried in an oven at 80°C for 10 hours, and the solution obtained above was transferred to a crucible so that the filling degree in the crucible was 3vol.%-10vol.%. The crucible containing the solution was placed in a muffle furnace, heated to 400 °C at a heating rate of 2 °C / min and kept for 6 h to obtain a brown-black sample. Such as figure 1 , the product is Mn with pure phase spinel structure 3 o 4 ;Such as figure 2 , the obtained product has a porous core-shell structure, its outer diameter is 0.40 μm-1.60 μm, and its inner diameter is 0.45 μm-0.90 μm.

[0039] The metal oxide materials obtained above were used as electrode catalyst materials to study th...

Embodiment 2

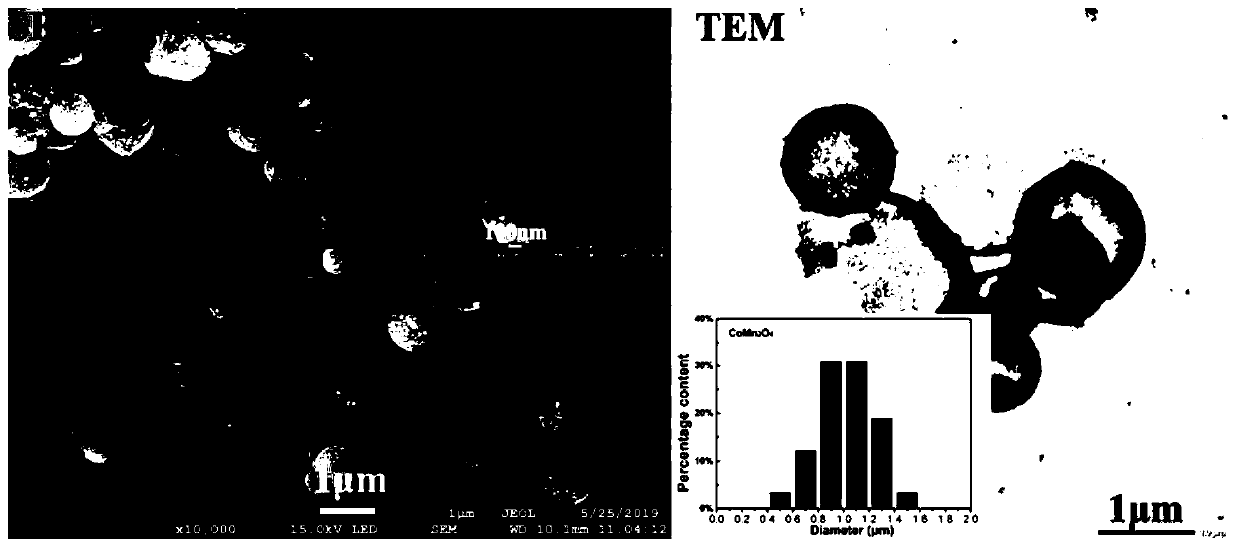

[0044] At room temperature, mix 30ml of ethylene glycol with 20ml of anhydrous methanol, and stir for 10min to obtain a homogeneous solution. Weighed 0.67 mmol of cobalt acetate and 1.33 mmol of manganese acetate and added to the above solution, and stirred at room temperature for 24 hours to obtain a dark brown mixed solution. The manganese-cobalt mixed solution was dried in an oven at 80°C for 10 hours, and the solution obtained above was transferred to a crucible so that the filling degree in the crucible was 3vol.%-10vol.%. The crucible containing the solution was placed in a muffle furnace, heated to 400 °C at a heating rate of 2 °C / min and kept for 6 h to obtain a brown-black sample. Such as figure 1 , the product is pure phase spinel structure CoMn 2 o 4 ;Such as image 3 , the obtained product is a porous spherical shell structure, and its outer diameter is 0.40 μm-1.60 μm.

[0045] Adopt the same method as embodiment 1 to test the CoMn of porous spherical shell t...

Embodiment 3

[0047] At room temperature, mix 30ml of ethylene glycol with 20ml of anhydrous methanol, and stir for 10min to obtain a homogeneous solution. Weighed 1.33 mmol of cobalt acetate and 0.67 mmol of manganese acetate and added to the above solution, and stirred at room temperature for 24 hours to obtain a dark red mixed solution. The manganese-cobalt mixed solution was dried in an oven at 80°C for 10 hours, and the solution obtained above was transferred to a crucible so that the filling degree in the crucible was 3vol.%-10vol.%. The crucible containing the solution was placed in a muffle furnace, heated to 400°C at a heating rate of 2°C / min and kept for 6h to obtain a black sample. Such as figure 1 , the product is pure phase spinel structure MnCo 2 o 4 ;Such as Figure 4 , the obtained product is a porous spherical hollow structure with an outer diameter of 0.10 μm-0.50 μm.

[0048] The MnCo of porous hollow spherical structure is tested by the same method as in Example 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com