Edible apple enzyme beverage and preparation method thereof

An enzyme beverage, apple technology, applied in the direction of bacteria, application, food science, etc. used in food preparation, can solve the problem of difficulty in controlling product quality, restricting the development and utilization of enzyme products, and unable to keep nutrients and active substances beneficial. Microbial flora, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

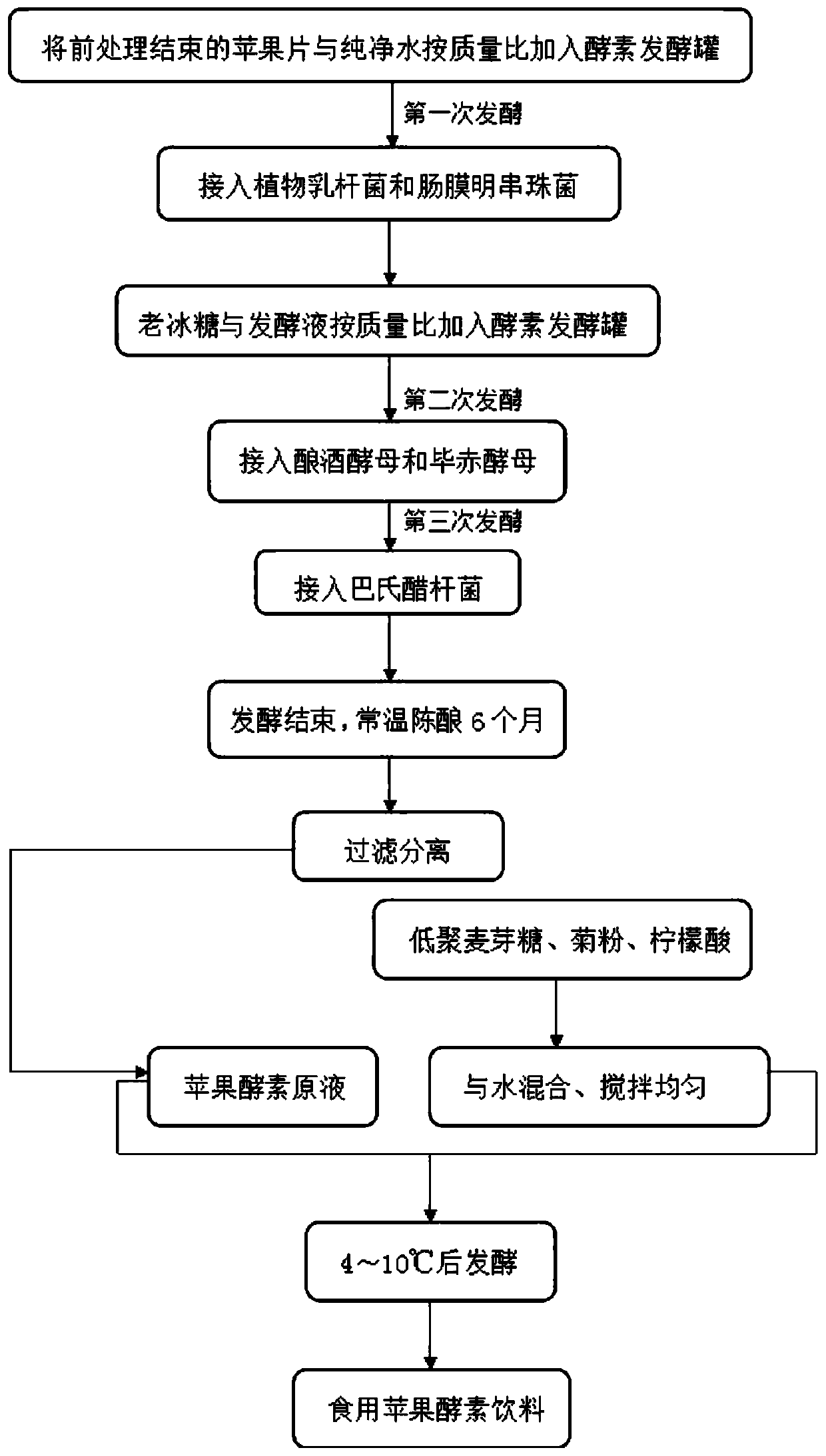

[0021] In the present invention, the preparation method of described apple enzyme stoste comprises the following steps:

[0022] 1) inoculating Lactobacillus plantarum and Leuconostoc enterococci into a mixture of apple slices and water, and performing the first non-heating fermentation at room temperature for 5-7 days to obtain the first fermentation liquid;

[0023] 2) mixing the first fermented liquid obtained in step 1) with rock sugar, inoculating Saccharomyces cerevisiae and Pichia pastoris, and carrying out the second normal temperature non-heating fermentation for 7-10 days to obtain the second fermented liquid;

[0024] 3) inoculating Acetobacter pasteurianum into the second fermented liquid obtained in step 2), carrying out the third non-heating fermentation at normal temperature for 10-15 days, aging for 3-6 months, and filtering the supernatant to obtain the apple enzyme stock solution.

[0025] In the invention, the mixture of apple slices and water is inoculated ...

Embodiment 1

[0040] 1. Apple enzyme stock solution: Add the pretreated apple slices to purified water at a mass ratio of 300g:1000mL into the enzyme fermenter, inoculate the activated Lactobacillus plantarum and Leuconostoc enterococci seed solution, the ratio of the two is 1 :1, the inoculum size is 4%, and the inoculum concentration is 1.0×10 7 CFU / mL, leave to ferment at room temperature for 6 days; further add old rock sugar and fermented liquid to the fermenter according to the mass ratio of 100g:1000mL, then insert Saccharomyces cerevisiae and Pichia pastoris, the ratio of the two is 1:1, The inoculum volume was 3%, and the inoculum concentration was 1.0×10 6 CFU / mL, left to ferment at room temperature for 8 days; further inoculated with Acetobacter pasteurianus, the inoculum size was 10%, and the inoculum concentration was 1.0×10 8 CFU / mL, fermented on a shaking table at room temperature for 12 days, when the soluble solids content in the fermentation liquid was 3-5% and no longer ...

Embodiment 2

[0045] 1. Apple enzyme stock solution: Add the pretreated apple slices to purified water at a mass ratio of 300g:1000mL into the enzyme fermenter, inoculate the activated Lactobacillus plantarum and Leuconostoc enterococci seed solution, the ratio of the two is 1 :1, the inoculum size is 4%, and the inoculum concentration is 1.0×10 7 CFU / mL, leave to ferment at room temperature for 6 days; further add old rock sugar and fermented liquid to the fermenter according to the mass ratio of 100g:1000mL, then insert Saccharomyces cerevisiae and Pichia pastoris, the ratio of the two is 1:1, The inoculum volume was 3%, and the inoculum concentration was 1.0×10 6 CFU / mL, left to ferment at room temperature for 8 days; further inoculated with Acetobacter pasteurianus, the inoculum size was 10%, and the inoculum concentration was 1.0×10 8 CFU / mL, fermented on a shaking table at room temperature for 12 days, when the soluble solids content in the fermentation liquid was 3-5% and no longer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com