Ni(OH)2 nanoparticle modified SrTiO3 composite catalyst and preparation method and application thereof

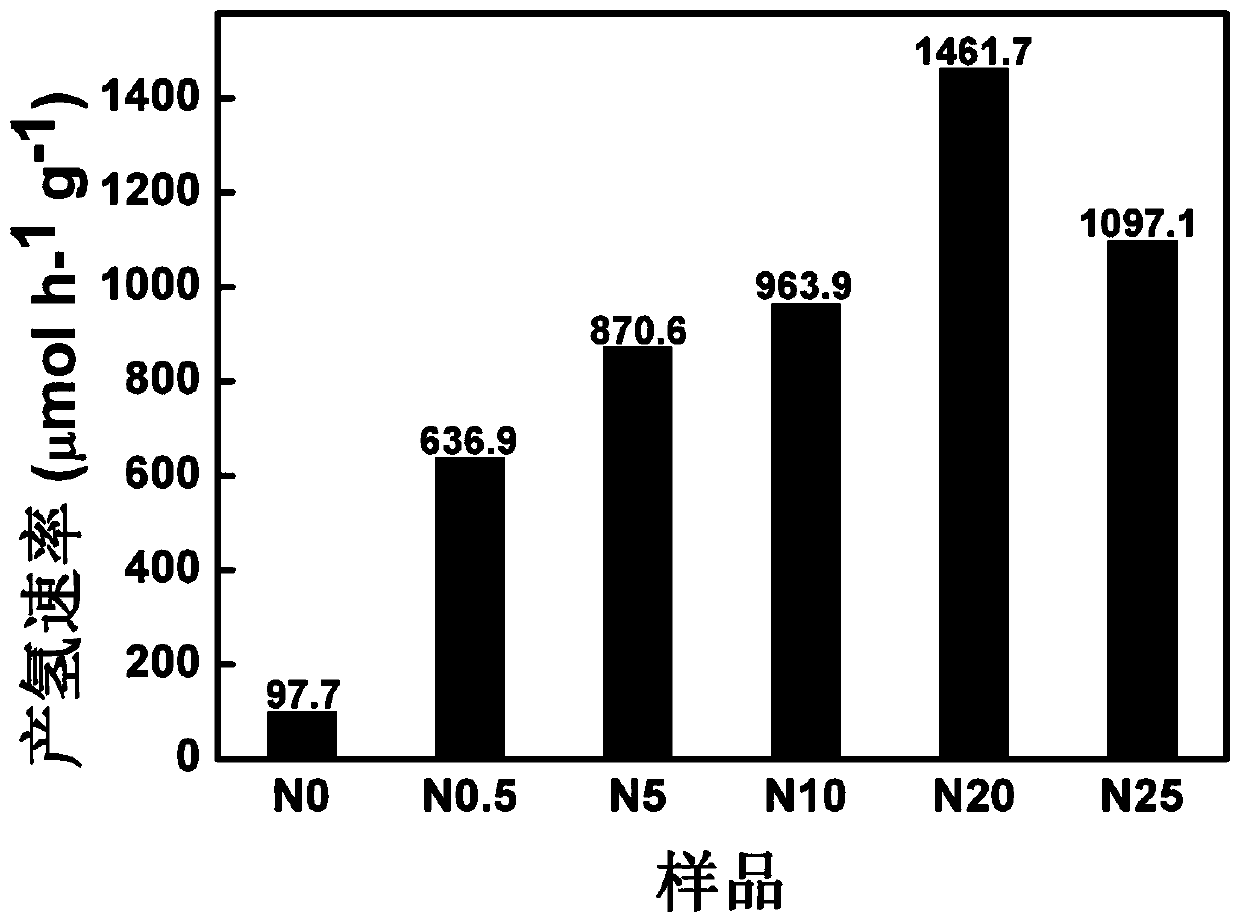

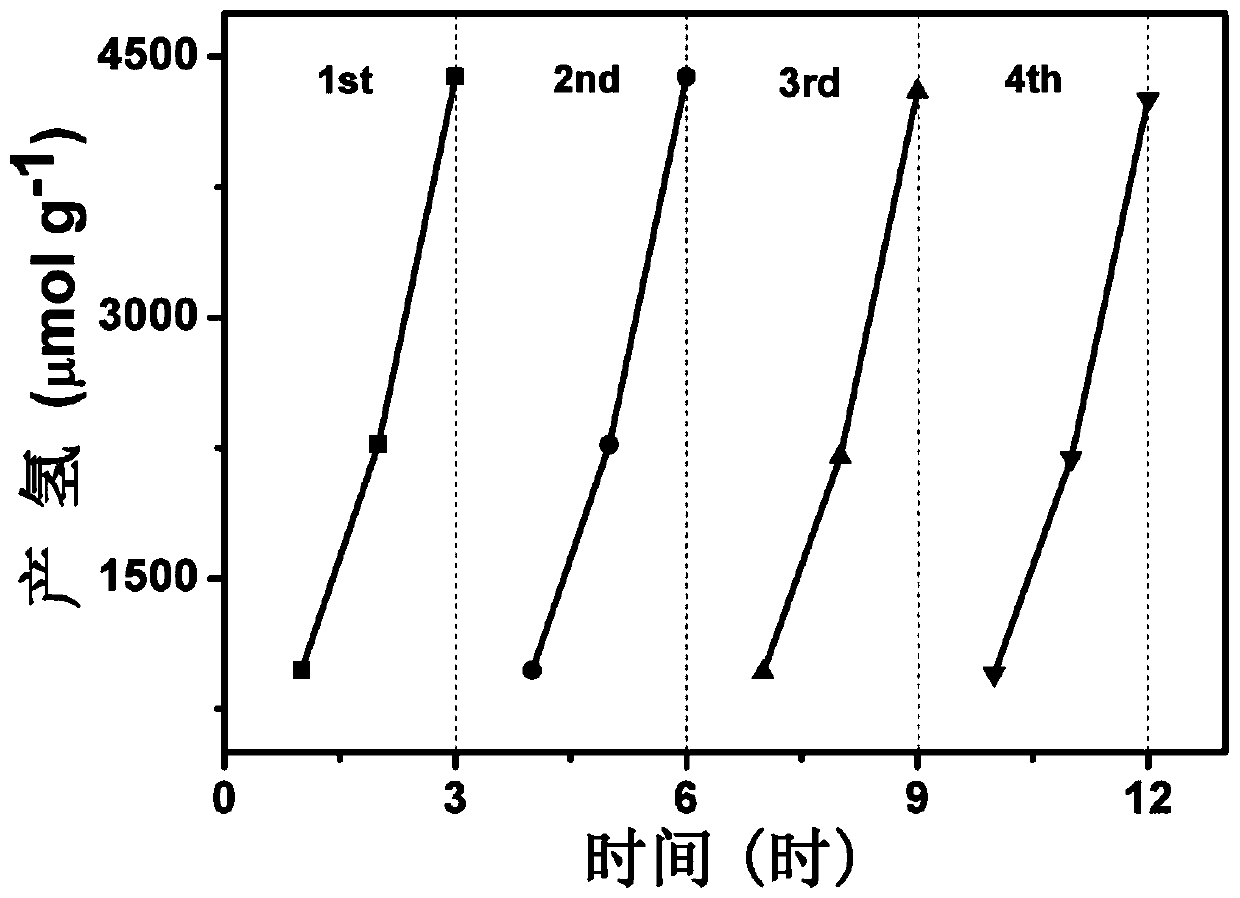

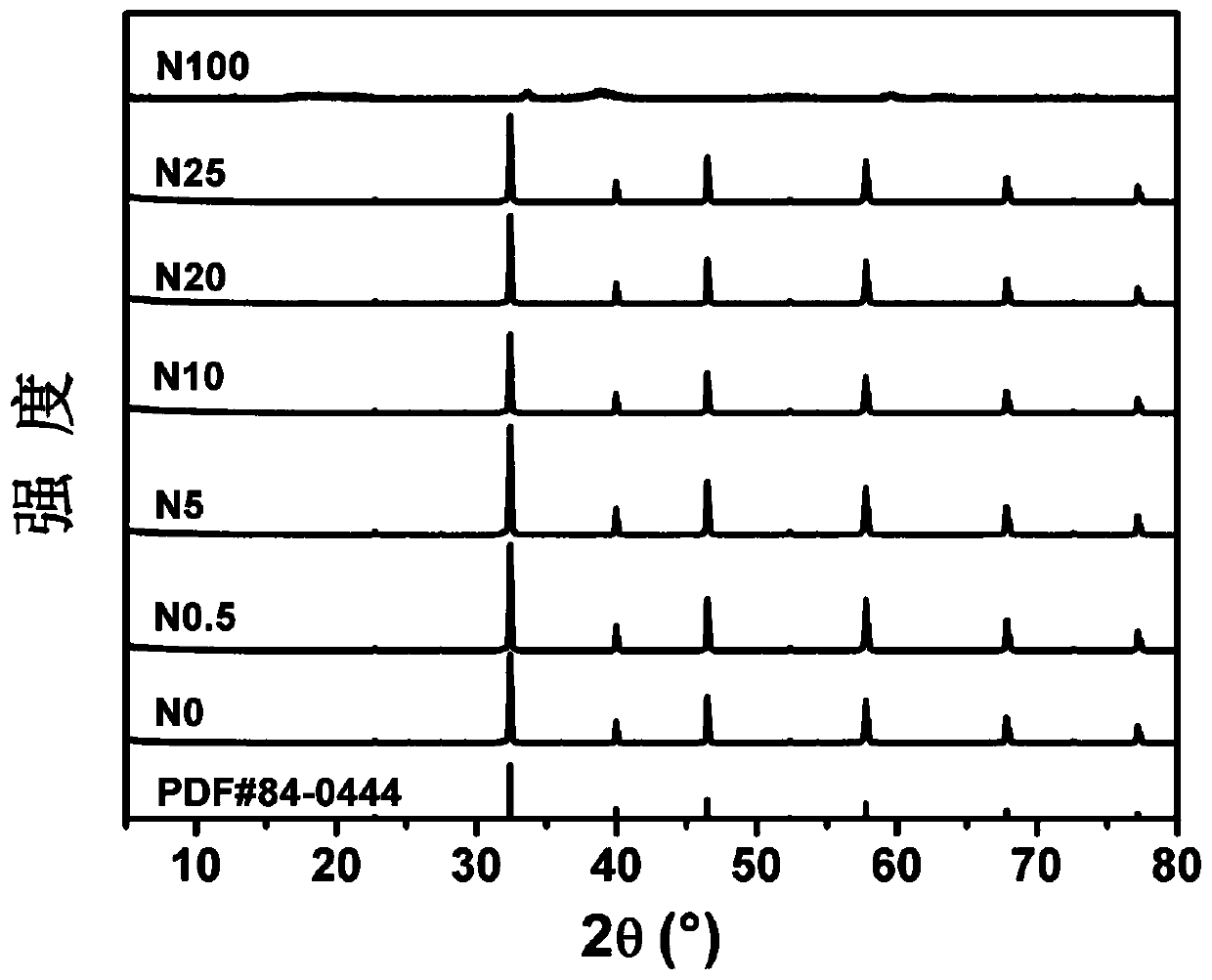

A nanoparticle modification and composite catalyst technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as limiting practical applications, and achieve excellent production Hydrogen activity, good photochemical stability, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example is Ni(OH) 2 The preparation method of the composite catalyst with a molar content of 0.5%, it may further comprise the steps:

[0032] Accurately weigh 0.507g SrTiO 3 , dispersed in the prepared sodium hydroxide solution 50ml, ultrasonic 30min. After the sonication, 276 μl of the prepared nickel nitrate solution was slowly added dropwise under the condition of magnetic stirring, and then kept stirring for 4 hours at room temperature. Finally get 0.5% Ni(OH) 2 / SrTiO 3 Composite catalyst. Finally, wash with ethanol and deionized water for 6 times, and dry in an oven at 60° C. for 12 hours.

Embodiment 2

[0034] This example is Ni(OH) 2 The preparation method of the composite catalyst that molar content is 5%, it may further comprise the steps:

[0035] Accurately weigh 0.507g SrTiO 3 , dispersed in the prepared sodium hydroxide solution 50ml, ultrasonic 30min. After the sonication, under the condition of magnetic stirring, 2.9ml of the prepared nickel nitrate solution was slowly added dropwise, and then kept stirring at room temperature for 4h. Finally get 5% Ni(OH) 2 / SrTiO 3 Composite catalyst. Finally, wash with ethanol and deionized water for 6 times, and dry in an oven at 60° C. for 12 hours.

Embodiment 3

[0037] This example is Ni(OH) 2 The preparation method of the composite catalyst that molar content is 10%, it comprises the following steps:

[0038] Accurately weigh 0.507g SrTiO 3, dispersed in the prepared sodium hydroxide solution 50ml, ultrasonic 30min. After the sonication, under the condition of magnetic stirring, 6.14ml of the prepared nickel nitrate solution was slowly added dropwise, and then kept stirring at room temperature for 4h. Finally got 10%Ni(OH) 2 / SrTiO 3 Composite catalyst. Finally, wash with ethanol and deionized water for 6 times, and dry in an oven at 60° C. for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com