Method for preparing superhydrophobic coating on surface of SiO2 glass

A super-hydrophobic coating and glass surface technology, applied in the coating and other directions, can solve the problems of reduced hydrophobicity, easy wear, poor adhesion, etc., and achieve the effect of short cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

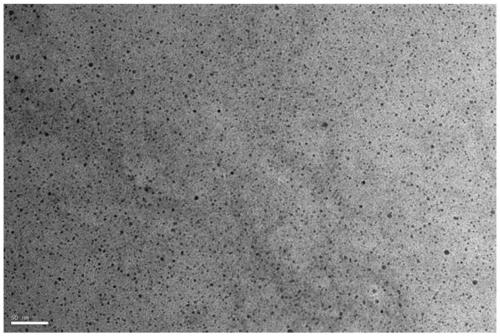

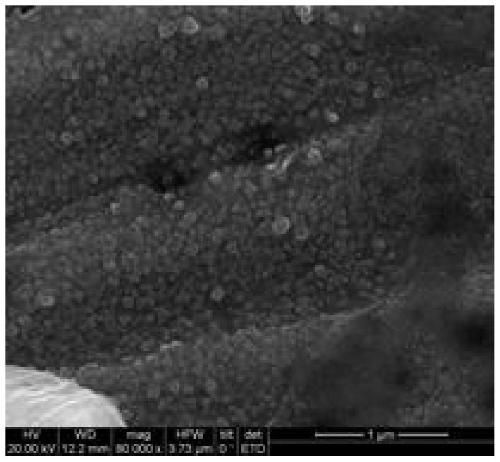

Image

Examples

Embodiment 1

[0044] In this example, a SiO 2 A method for preparing a superhydrophobic coating on a glass surface, comprising the steps of:

[0045] (1) SiO 2 Glass pretreatment: Soak the glass in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide for 4 hours, the volume ratio of 98% concentrated sulfuric acid and 30% hydrogen peroxide is 3:1, use Rinse with deionized water, then soak in the mixed solution of water, hydrogen peroxide and ammonia water, boil the mixed solution for 0.8h, the volume ratio of water, hydrogen peroxide and ammonia water is 4:1:1, and then use deionized water Rinse well, blow dry with nitrogen, then soak in 3-aminopropyltriethoxysilane solution for 22h, 3-aminopropyltriethoxysilane solution refers to 3-aminopropyltriethoxysilane, anhydrous Ethanol, deionized water, and acetic acid are prepared according to the volume ratio of 1:48:1:0.25, cleaned with ethanol, and dried with nitrogen gas for later use;

[0046] (2) Soak the pretreated...

Embodiment 2

[0052] In this example, a SiO 2 A method for preparing a superhydrophobic coating on a glass surface, comprising the steps of:

[0053] (1) SiO 2 Glass pretreatment: Soak the glass in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide for 5 hours, the volume ratio of 98% concentrated sulfuric acid and 30% hydrogen peroxide is 7:3, use Rinse with deionized water, then soak in a mixed solution of water, hydrogen peroxide and ammonia water, boil the mixed solution for 1 hour, the volume ratio of water, hydrogen peroxide and ammonia water is 5:1:1, and then rinse with deionized water Clean, dry with nitrogen, then soak in 3-aminopropyltriethoxysilane solution for 24h, 3-aminopropyltriethoxysilane solution refers to 3-aminopropyltriethoxysilane, absolute ethanol , deionized water, and acetic acid are prepared according to the volume ratio of 1:48:1:0.25, cleaned with ethanol, and dried with nitrogen for later use;

[0054] (2) Soak the pretreated glass ...

Embodiment 3

[0060] In this example, a SiO 2 A method for preparing a superhydrophobic coating on a glass surface, comprising the steps of:

[0061] (1) SiO 2 Glass pretreatment: Soak the glass in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide for 6 hours, the volume ratio of 98% concentrated sulfuric acid and 30% hydrogen peroxide is 2:1, use Rinse with deionized water, then soak in the mixed solution of water, hydrogen peroxide and ammonia water, boil the mixed solution for 1.2h, the volume ratio of water, hydrogen peroxide and ammonia water is 6:1:1, and then use deionized water Rinse well, blow dry with nitrogen, then soak in 3-aminopropyltriethoxysilane solution for 26h, 3-aminopropyltriethoxysilane solution refers to 3-aminopropyltriethoxysilane, anhydrous Ethanol, deionized water, and acetic acid are prepared according to the volume ratio of 1:48:1:0.25, cleaned with ethanol, and dried with nitrogen gas for later use;

[0062] (2) Soak the pretreated...

PUM

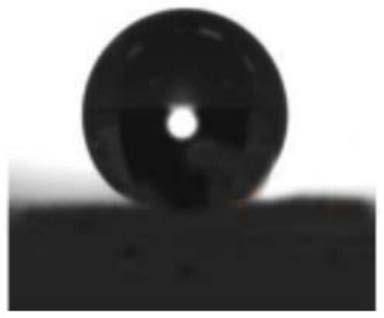

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com