Ceramic film material, catalytic electrode and preparation method and application thereof

A ceramic film and catalytic electrode technology, which is applied in ceramic products, applications, battery electrodes, etc., can solve problems such as insufficient stability and catalytic activity, insufficient ability to activate catalysts, and expensive catalytic electrodes, so as to achieve good catalytic activity and improve catalytic performance. The effect of activity, circulation and exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

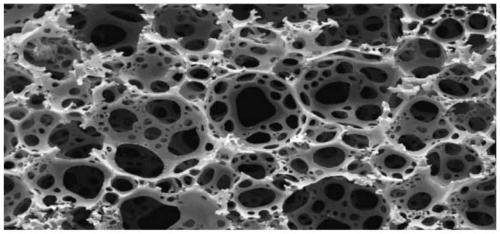

Image

Examples

preparation example Construction

[0041] Embodiments of the present invention also provide a method for preparing a catalytic electrode, which is characterized in that it includes the following steps:

[0042] S01: the mass fraction is 10%-20% organic zirconium compounds, 0.3%-2.8% organic hafnium compounds, 1.0%-4.2% yttrium, cerium compounds, 3%-5.5% carbon nanofibers, 2.5%- 8.0% nano-carbon black is dispersed in 70% organic solvent to form a ceramic slurry;

[0043] S02: coating the slurry on the substrate, drying and sintering to obtain a ceramic film layer loaded on the substrate;

[0044] S03: the organic platinum compound of 2.5%-18%, the nano-carbon black of 3.5%-20%, the organic binder of 4.5%-12%, and the dispersant of 0.5%-2.0% are dispersed in the mass fraction of S03. The catalytic slurry prepared with 70% organic solvent is loaded on the ceramic film layer, and the catalytic electrode is obtained through drying, calcining and sintering.

[0045] Specifically, in step S01, the organic solvent us...

Embodiment 1

[0051] This embodiment provides a kind of ceramic film material prepared by the following method:

[0052] The mass fraction is 10% biscyclopentadienyl or bis(methylcyclopentadienyl) zirconium dichloride, 2.8% hafnium isooctanoate; 1.0% yttrium nitrate, 1.0% cerium oxalate, 5.5% Carbon fiber, 2.5% nano-carbon black, and PS micropowder are dispersed in the methyl carbonate of the balance percentage and fully ball-milled to make a ceramic slurry;

[0053] Coat the ceramic slurry on the substrate, dry it at 120°C, then heat it up to 900°C at a rate of 3°C, heat and calcinate it in an air atmosphere in a box-type sintering furnace, keep it warm for 0.5h, and finally activate it by laser Sintering to obtain porcelain thin film material.

[0054] This embodiment also provides a catalytic electrode, which is prepared by the following method on the basis of the above-mentioned ceramic thin film material:

[0055] The mass fraction is 3% of divinyl dichloroplatinum, 4% of nano-carbon...

Embodiment 2

[0057] This embodiment provides a kind of ceramic film material prepared by the following method:

[0058] The mass fraction is 20% zirconium isooctanoate, 0.3% hafnium isooctanoate; 2.1% yttrium (III) isopropoxide, 2.1% cerium carbonate (III), 3% carbon fiber, 8% PMMA fine powder dispersion Fully ball-milling and dispersing in the methyl carbonate of the remaining percentage makes ceramic slurry;

[0059] Coat the ceramic slurry on the substrate, dry it at 120°C, then heat up to 900°C at a rate of 3°C, heat and calcinate in an air atmosphere in a box-type sintering furnace, keep it warm for 2 hours, and finally sinter by laser activation A porcelain thin film material is obtained.

[0060] This embodiment also provides a catalytic electrode, which is prepared by the following method on the basis of the above-mentioned ceramic thin film material:

[0061] The mass fraction is 18% of dinitrosodiammine platinum, 3.5% of nano-carbon black, 12% of organic binder, 2% of dispersan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrochemically active area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com