Preparation method of ZrO2-based oxygen sensitive element co-sintering platinum electrode

A technology of sensitive components and platinum electrodes, which is applied in the field of electrode preparation, can solve the problems of blocking the catalytic active area of platinum electrodes and reducing the catalytic activity of electrodes, and achieve high bonding strength, reduce the difference in thermal expansion coefficient, and avoid detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

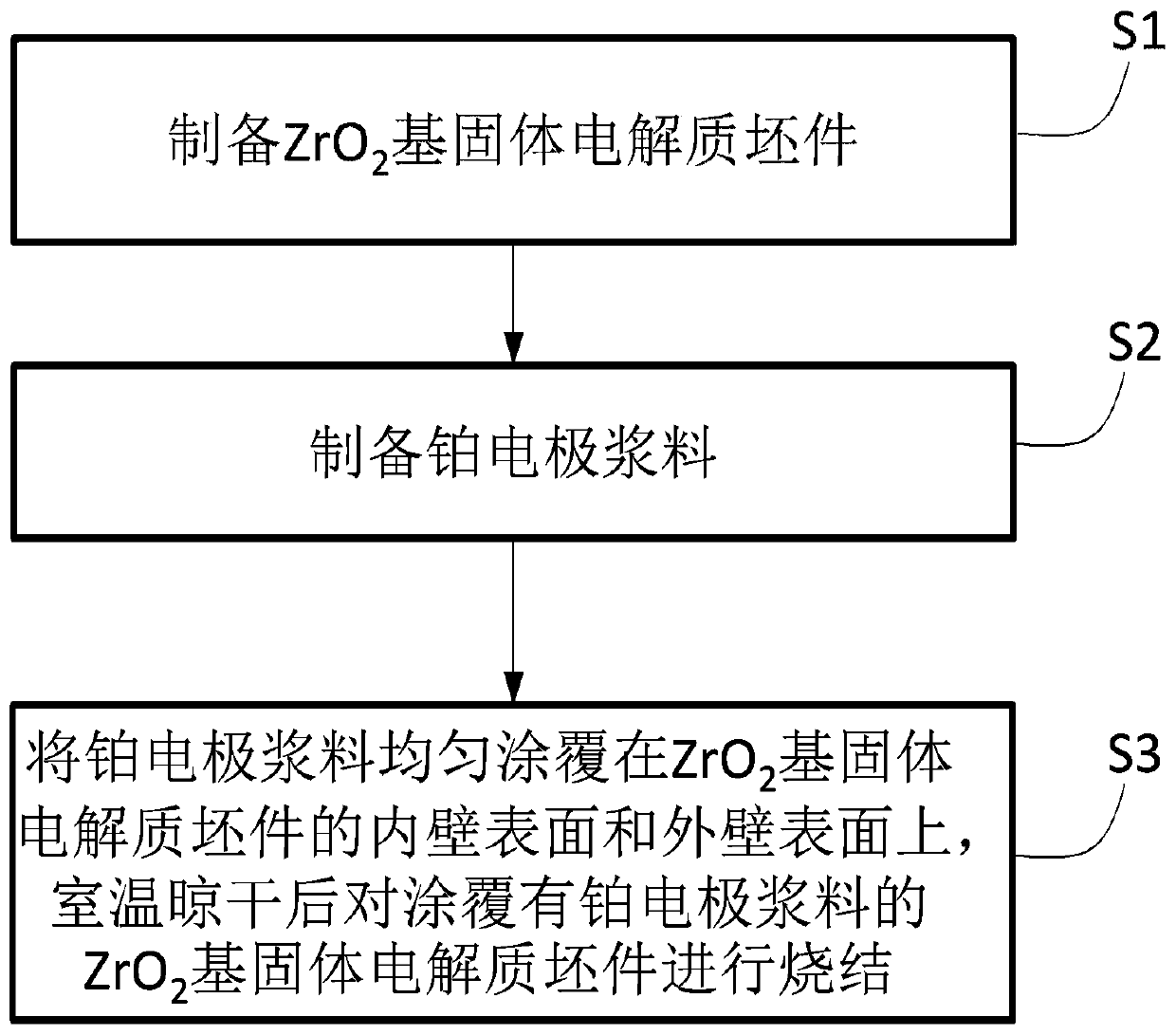

[0032] ZrO of the present invention 2 The preparation method of the oxygen-based sensitive element co-sintered platinum electrode mainly includes the following steps:

[0033] S1. Preparation of ZrO 2 Base solid electrolyte blank;

[0034] S2. Prepare platinum electrode slurry; and

[0035] S3. Coating the platinum electrode slurry evenly on the ZrO 2 On the inner wall surface and outer wall surface of the base solid electrolyte blank, after drying at room temperature, the ZrO coated with platinum electrode slurry 2 The base solid electrolyte blank is sintered.

[0036] In step S1, ZrO 2 The preparation of the base solid electrolyte blank can adopt the cold isostatic pressing technology to compress 5mol%-8mol%Y 2 o 3 Doped ZrO 2 The powder is pressed into a tube to produce a tube blank. Among them, 5mol%-8mol%Y 2 o 3 Doped ZrO 2 The powder refers to the ZrO 2 The powder is doped with 5%-8% Y by mole 2 o 3 Powdered material.

[0037]In step S2, the preparation p...

experiment example 1

[0044] First, the preparation of the platinum electrode slurry is carried out: firstly, the metal oxide additives are prepared, respectively 10% Al by weight percentage 2 o 3 , 80% ZrO 2 Base solid electrolyte powder (6mol% Y 2 o 3 Doped ZrO 2 ) and 10% CaO to prepare metal oxide additives; then, according to weight percent, respectively 5% metal oxide additives, 10% methylcellulose, 8% eucalyptol, 10% terpineol and 67% of roughly spherical ultrafine platinum powder with a particle size of 1.0 μm is used for batching preparation, and metal oxide additives and ultrafine platinum powder are mixed and fully dispersed, and then methylcellulose, eucalyptol and pine Oleyl alcohol, ultrasonically disperse for 1.5h, or use a ball mill to grind for 10h to make a platinum electrode slurry.

[0045] Then, ZrO 2 Preparation of co-sintered platinum electrodes for oxygen-based sensitive elements: coating the prepared platinum electrode slurry on the prepared tubular ZrO 2 On the surf...

experiment example 2

[0048] First, the preparation of platinum electrode slurry is carried out: the metal oxide additives are prepared, respectively 13% Al by weight percentage 2 o 3 , 76% ZrO 2 Base solid electrolyte powder (6mol% Y 2 o 3 Doped ZrO 2 ) and 11% CaO to formulate metal oxide additives; then, according to weight percent, respectively 4.6% metal oxide additives, 6% epoxy resin, 10% castor oil fatty acid, 10% methyl ethyl ketone and The ratio of 69.4% of roughly spherical ultrafine platinum powder with a particle size of 1.5 μm is prepared for batching, and the metal oxide additive and ultrafine platinum powder are mixed and fully dispersed, and then epoxy resin, castor oil fatty acid and methyl Ethyl ketone, ultrasonically disperse for 1.5h, or use a ball mill to grind for 10h to make a platinum electrode slurry.

[0049] Then, ZrO 2 Preparation of co-sintered platinum electrodes for oxygen-based sensitive elements: coating the prepared platinum electrode slurry on the tubular Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com