Silane-blocked polyether sealant and preparation method and application thereof

A technology of silane-terminated polyether and sealant, which is applied in the field of sealant, can solve the problems of long overall process time and insufficient elongation performance of sealant, and achieve excellent adhesion, moderate tensile strength and good elastic recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A silane-terminated polyether sealant consists of the following components by mass percentage:

[0025] Silane-terminated polyether S303H—20%, plasticizer epoxyacetyl ricinoleate—20%, light stabilizer B75—1%, polyamide wax—1.6%, solid powder GCC—39%, PCC— 13% and fumed silica—2%, dewatering agent diisobutyl ether group bis(trimethoxy)silane—1.6%, coupling agent N-2-(aminoethyl)-3-aminopropyltrimethyl Oxysilane (KH-792)—1.6%, catalyst U-220H—0.2%.

[0026] A kind of its preparation method of silane-terminated polyether sealant, comprises the following steps:

[0027] (1) Add silane-terminated polyether, plasticizer and UV absorber to the double planetary dynamic mixer under nitrogen condition, and stir for 20-30min under vacuum condition (≤30mbar);

[0028] (2) Add auxiliary additives and solid powder under nitrogen condition, heat up to 90-110°C and vacuumize (≤30mbar) and stir for 1.5-2.0h, cool down to 45-55°C and add dewatering agent and distillate under nitrogen c...

Embodiment 2

[0032] A silane-terminated polyether sealant for prefabricated buildings, consisting of the following components by mass percentage:

[0033] Silane-terminated polyether HMS-1303—20%, plasticizer epoxyacetyl ricinoleate—20%, light stabilizer B75—1%, polyamide wax—1.6%, solid powder GCC—39%, PCC—13% and fumed silica—2%, water removal agent diisobutyl ether group bis(trimethoxy)silane—1.6%, coupling agent N-2-(aminoethyl)-3-aminopropyl Trimethoxysilane (KH-792)—1.6%, catalyst U-220H—0.2%.

[0034] The preparation method is the same as in Example 1.

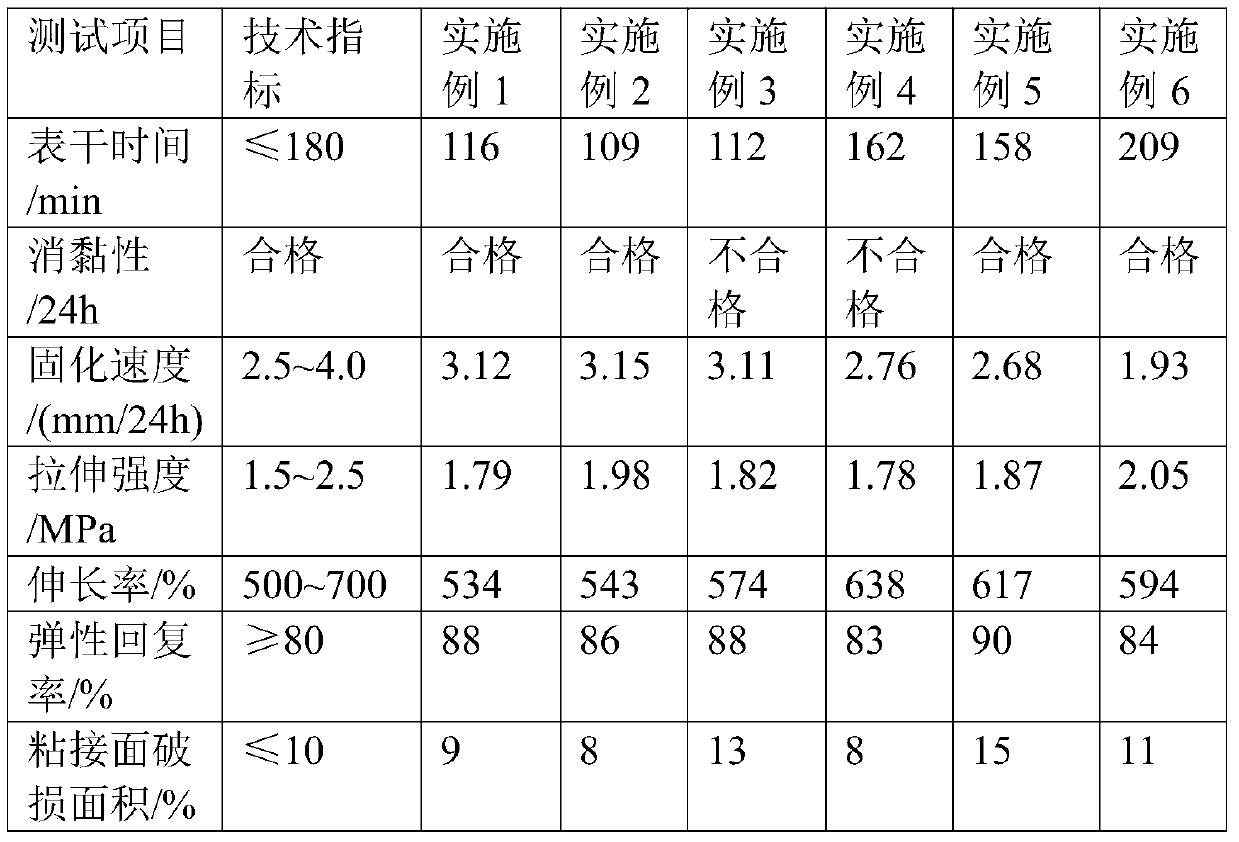

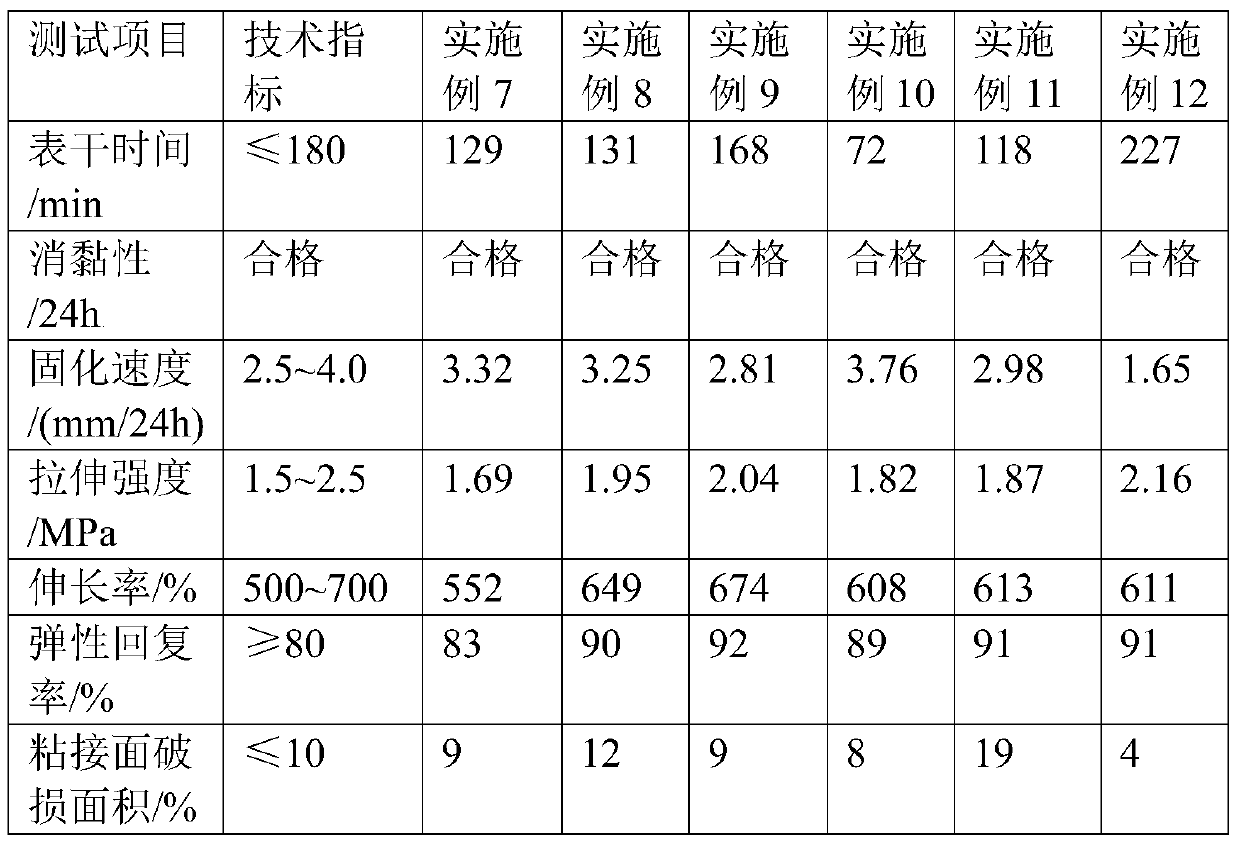

[0035] The test results are shown in Table 1.

Embodiment 3

[0037] A silane-terminated polyether sealant consists of the following components by mass percentage:

[0038] Silane-terminated polyether HMS-1303—20%, plasticizer PPG2000—20%, light stabilizer B75—1%, organically modified montmorillonite—1.6%, solid powder GCC—39%, PCC—13% And fumed silica—2%, dewatering agent diisobutyl ether base bis(trimethoxy)silane—1.6%, coupling agent isopropyl tri(dodecylbenzenesulfonyl) titanate—1.6 %, catalyst KAT226—0.2%.

[0039] The preparation method is the same as in Example 1.

[0040] The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com