High-thermal-conductivity silicon nitride ceramic material for 3D printing, and product thereof

A technology of silicon nitride ceramics and silicon nitride ceramic powder, which is applied in the field of 3D printing, can solve the problems of poor product quality stability, small elongation at break, and low dimensional accuracy, and achieve improved quality stability and elongation at break Moderate, excellent thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A 3D printing high thermal conductivity silicon nitride ceramic material is made of raw materials including the following parts by weight:

[0056] 100-120 parts of silicon nitride ceramic powder,

[0057] Silicon carbide fiber 17-22 parts,

[0058] 35-44 parts of ethoxylated trimethylolpropane triacrylate,

[0059] 24-30 parts of aliphatic polyurethane diacrylate,

[0060] 9-12 parts of tetrakis (3-mercaptopropionic acid) pentaerythritol ester,

[0061] 0.18-0.24 parts of photoinitiator,

[0062] Inhibitor 0.020~0.025 parts,

[0063] 4-6 parts of dispersant,

[0064] 3.5 to 4.5 parts of defoamer.

[0065] Preferably, the 3D printing high thermal conductivity silicon nitride ceramic material is made of raw materials including the following parts by weight:

[0066] Silicon nitride ceramic powder 110 parts,

[0067] Silicon carbide fiber 19.5 parts,

[0068] 39.5 parts of ethoxylated trimethylolpropane triacrylate,

[0069] 27 parts of aliphatic polyurethane di...

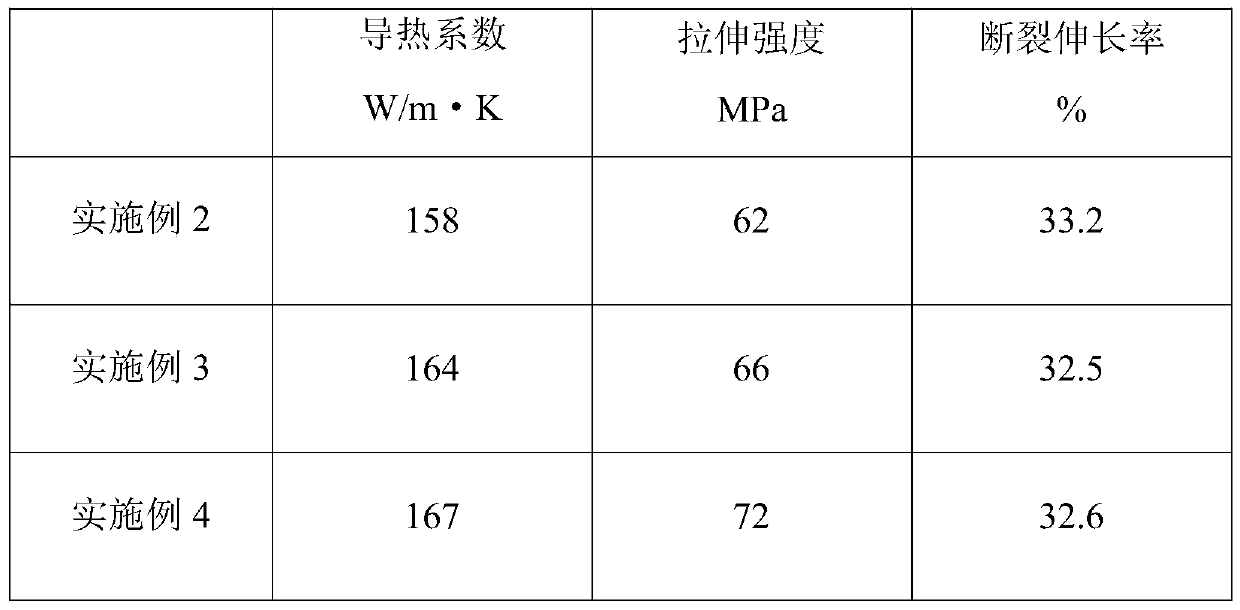

Embodiment 2

[0083] A 3D printing high thermal conductivity silicon nitride ceramic material is made of raw materials including the following parts by weight:

[0084] Silicon nitride ceramic powder 100 parts,

[0085] Silicon carbide fiber 17 parts,

[0086] 35 parts of ethoxylated trimethylolpropane triacrylate,

[0087] Aliphatic polyurethane diacrylate 24 parts,

[0088] 9 parts of tetrakis (3-mercaptopropionic acid) pentaerythritol ester,

[0089] 0.18 parts of photoinitiator,

[0090] 0.020 parts of polymerization inhibitor,

[0091] 4 parts of dispersant,

[0092] 3.5 parts of defoamer.

[0093] In this embodiment, the particle size of the silicon nitride ceramic powder is 0.4-0.6 μm.

[0094] In this embodiment, the photoinitiator is Irgacure784 from BASF Chemicals Co., Ltd.

[0095] In this embodiment, the polymerization inhibitor is pyrogallol.

[0096] In this embodiment, the dispersant is a mixture of ammonium polyacrylate and oleic acid.

[0097] In this embodiment, ...

Embodiment 3

[0101] A 3D printing high thermal conductivity silicon nitride ceramic material is made of raw materials including the following parts by weight:

[0102] 120 parts of silicon nitride ceramic powder,

[0103] Silicon carbide fiber 22 parts,

[0104] 44 parts of ethoxylated trimethylolpropane triacrylate,

[0105] Aliphatic polyurethane diacrylate 30 parts,

[0106] 12 parts of tetrakis (3-mercaptopropionic acid) pentaerythritol ester,

[0107] 0.24 parts of photoinitiator,

[0108] 0.025 parts of polymerization inhibitor,

[0109] 6 parts of dispersant,

[0110] 4.5 parts of defoamer.

[0111] In this embodiment, the particle size of the silicon nitride ceramic powder is 0.4-0.6 μm.

[0112] In this embodiment, the photoinitiator is Irgacure784 from BASF Chemicals Co., Ltd.

[0113] In this embodiment, the polymerization inhibitor is pyrogallol.

[0114] In this embodiment, the dispersant is a mixture of ammonium polyacrylate and oleic acid.

[0115] In this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com