Methanol modified fuel for reducing automobile exhaust gas

A technology of automobile exhaust and methanol, which is applied in the direction of fuel, fuel additives, liquid carbon-containing fuel, etc., to achieve the effects of reducing emissions, reducing corrosion, and removing carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

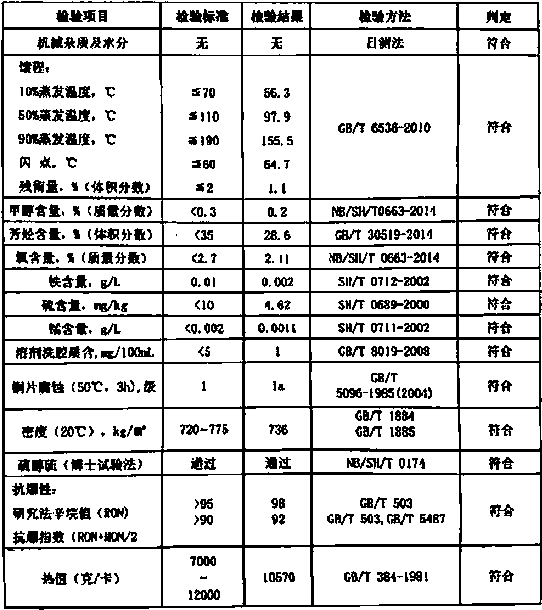

Image

Examples

preparation example Construction

[0019] The present invention also provides a kind of preparation method of the methanol modified fuel that reduces automobile tail gas, comprises the following steps:

[0020] Step 1: Add the dehydrated and modified methanol, alkylation, and 200# solvent oil in order in the reaction kettle, mix and let stand for 25 minutes;

[0021] Step 2: Add light oil and MTBE to mix, and let stand for 35 minutes;

[0022] Step 3: Put the anti-corrosion and anti-carbon additives into the reaction kettle in order. It is better to use the pipeline valve to fully dissolve and emulsify at a high flow rate at a high injection rate. Make cans, get high-quality products and let them stand still. After 2-3 hours, they will be finished products.

Embodiment

[0024] A methanol-modified fuel for reducing automobile exhaust, consisting of the following raw materials in parts by weight: 25 parts by weight of the modified methanol, 20 parts by weight of alkylation, 17 parts by weight of light oil, 8 parts by weight of MTBE, 200# 12 parts by weight of solvent oil and 1 part of additive; the parts by weight of the raw materials in the additive are: 260 parts of glycerin, 80,260 parts of Span, 600 parts of BHT501, 700 parts of benzotriazole, 700 parts of ferrocene 50 parts, 100 parts of sodium hydroxide; the modified methanol is composed of methanol and a modifier, the weight ratio of the two is: methyl alcohol: modifier=98:2, the weight of each component of the raw material in the modifier Parts are: 70 parts by weight of isopropanol, 14 parts by weight of cyclohexylamine, 7 parts by weight of sodium peroxide, 8 parts by weight of dimethyl carbonate, 9 parts by weight of isooctyl nitrate, 2,6-di-tert-butyl p-cresol 0.6 parts. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com