Al-TiC composite film and preparation process thereof

A composite thin film and preparation technology, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems of poor high temperature stability and low strength (hardness), and achieve good compactness and temperature stability The effect of good resistance and fast deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

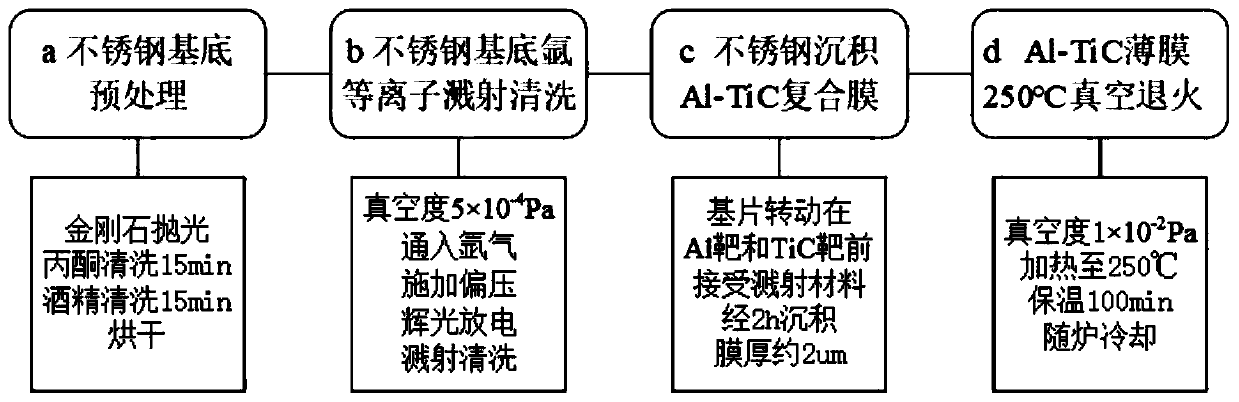

Method used

Image

Examples

Embodiment 1

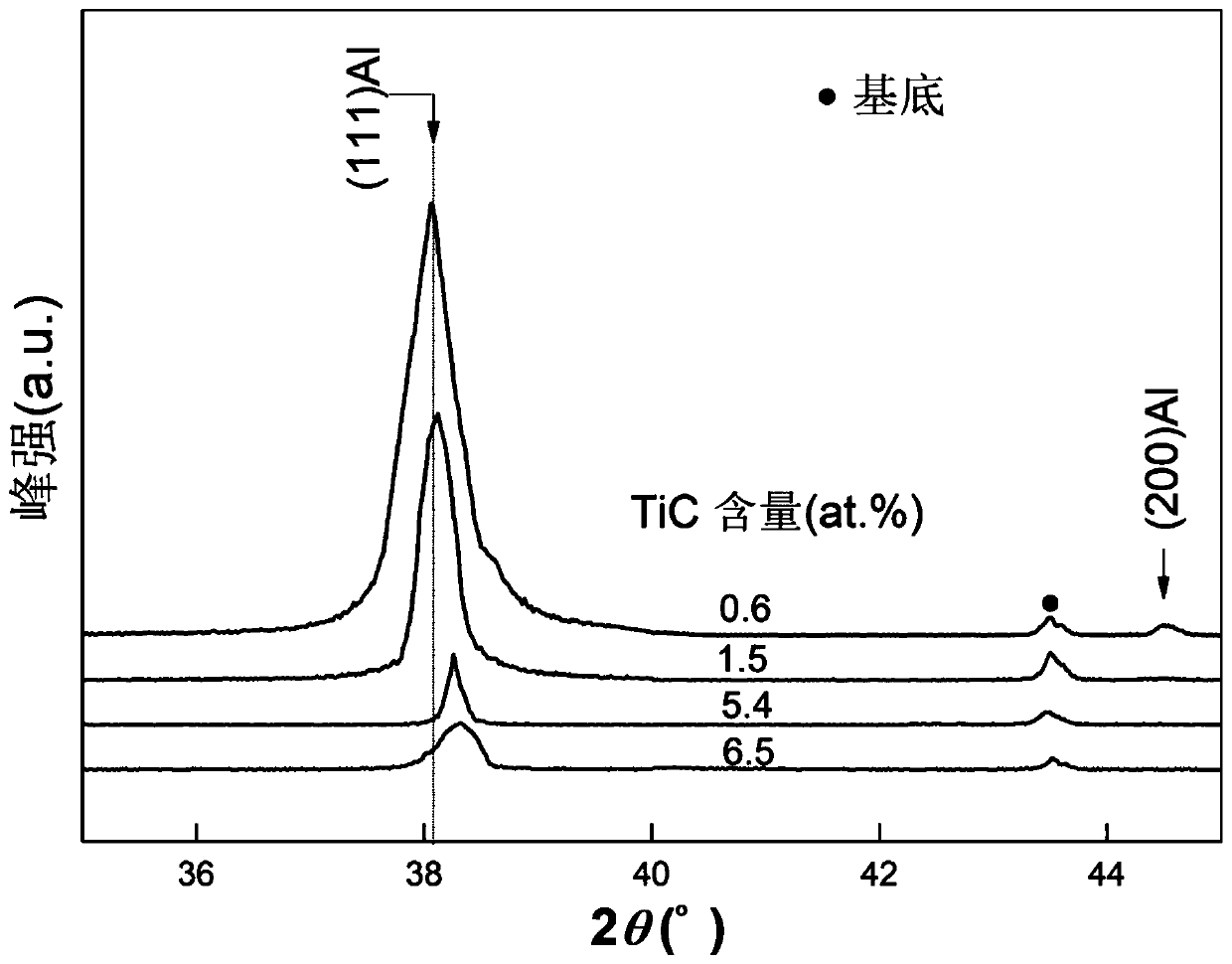

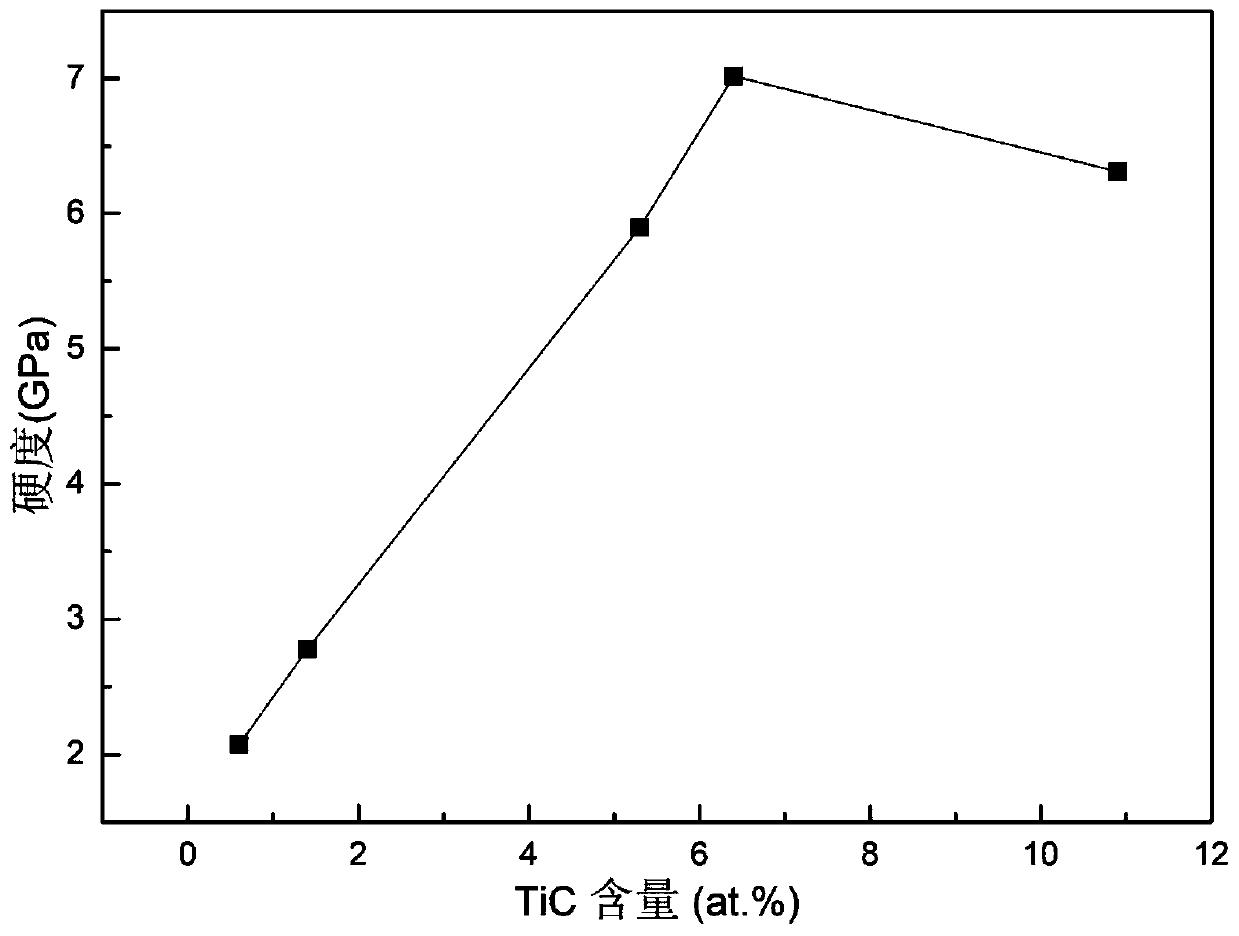

[0045] The specific technological parameters of the preparation method of the prepared Al-TiC composite film of the present invention are: TiC target sputtering power is 15W, Al target (DC) sputtering current is 0.4A, Al target (RF) sputtering power 220W, deposition After 2 hours, the film thickness is about 2 microns. In the Al-TiC composite thin film thus obtained, the content of TiC was 0.6% (atomic fraction, the same below), and the hardness of the thin film was 2.0 GPa. After annealing at 250°C, the hardness of the film is 1.9GPa; after annealing at 400°C, the hardness of the film is 1.64GPa. Without annealing at 250°C, the hardness of the film is 1.4GPa after direct annealing at 400°C.

Embodiment 2

[0047] The specific technological parameters of the preparation method of the prepared Al-TiC composite thin film of the present invention are: TiC target sputtering power is 30W, Al target (DC) sputtering current is 0.4A, Al target (RF) sputtering power 220W, deposition After 2 hours, the film thickness is about 2 microns. In the Al-TiC composite thin film thus obtained, the content of TiC was 1.5%, and the hardness of the thin film was 2.80 GPa. After annealing at 250°C, the hardness of the film is 2.60GPa; after annealing at 400°C, the hardness of the film is 1.86GPa. Without annealing at 250°C, the hardness of the film is 1.6GPa after direct annealing at 400°C.

Embodiment 3

[0049] The specific technological parameters of the preparation method of the prepared Al-TiC composite thin film of the present invention are: TiC target sputtering power is 100W, Al target (DC) sputtering current is 0.4A, Al target (RF) sputtering power 220W, deposition After 2 hours, the film thickness is about 2 microns. In the Al-TiC composite thin film thus obtained, the content of TiC was 5.4%, and the hardness of the thin film was 5.9 GPa. After annealing at 250℃, the hardness of the film is 5.56GPa; after annealing at 400℃, the hardness of the film is 3.33GPa. Without annealing at 250°C, the hardness of the film is 3.0GPa after direct annealing at 400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com