Aqueous acrylic internal-surface repair paint for container and preparation method for aqueous acrylic internal-surface repair paint

A water-based acrylic and container technology, applied in coatings and other directions, can solve problems such as different implementation efforts, organic solvent emissions, high VOCs pollution, etc., and achieve fast drying speed, good water resistance, and good film sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

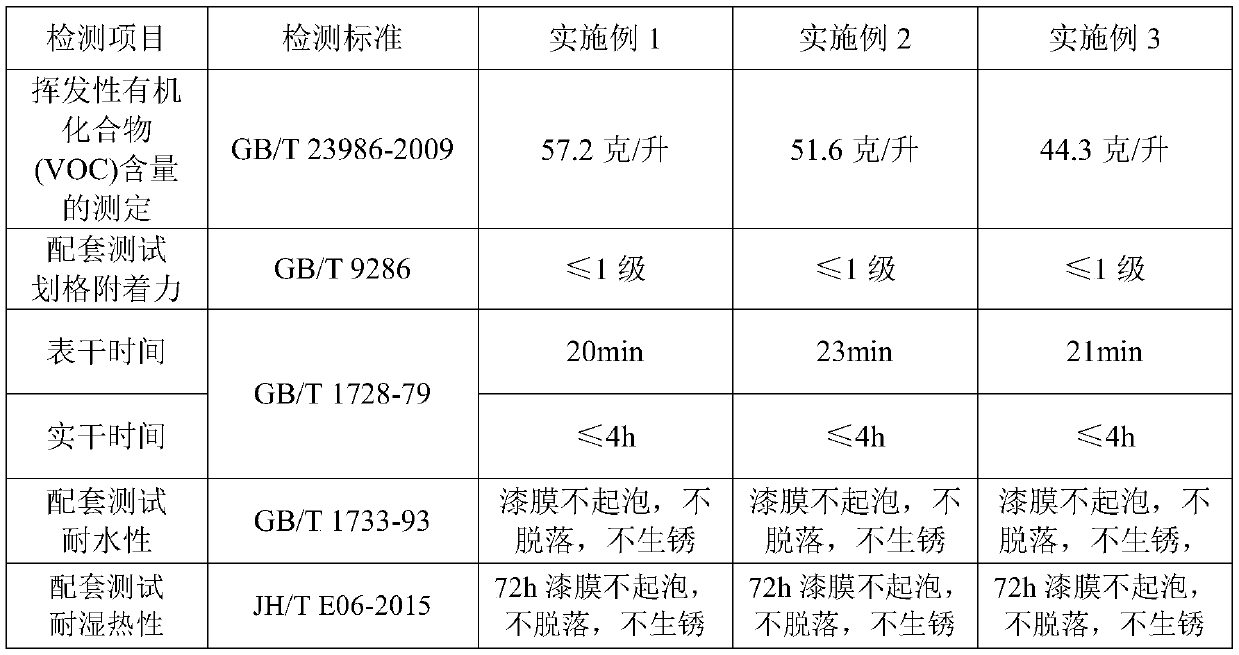

Examples

Embodiment 1

[0045] Take 10 parts of water, 0.2 parts of bactericide, 0.05 parts of anti-sedimentation agent, 0.3 parts of pH regulator, 0.8 parts of defoamer, 0.3 parts of dispersant, 10 parts of titanium dioxide, 0.3 parts of iron oxide black, 0.1 part of iron oxide yellow, acrylic acid Add 55 parts of resin and 20 parts of barium sulfate into the dispersing tank in turn, stir evenly, grind to a fineness of 50 μm, then add 3.8 parts of film-forming aid, 0.2 part of wetting and leveling agent, and 0.15 part of thickener to obtain .

[0046] The fungicide is Casson fungicide, Saul company, brand RS.

[0047] The anti-sedimentation agent is cellulose, Ashland Company, trade mark 3KB.

[0048] The pH adjuster is AMP-95.

[0049] The defoaming agent is a silicone type defoaming agent, Evonik Company, brand 901W.

[0050] The dispersant is ammonium acrylate dispersant, BYK Chemical Company, brand BYK-154.

[0051] The film-forming aid is alcohol ester twelve.

[0052] Wetting and leveling...

Embodiment 2

[0056]Take 15 parts of water, 0.3 parts of bactericide, 0.03 parts of anti-settling agent, 0.2 parts of pH regulator, 1.2 parts of defoamer, 0.6 parts of dispersant, 5 parts of titanium dioxide, 0.8 parts of iron oxide black, 0.3 parts of iron oxide yellow, acrylic acid 50 parts of resin, 15 parts of barium sulfate, 5 parts of talc powder, 5 parts of mica powder, add to the dispersion tank in turn, after stirring evenly, grind to a fineness of 40 μm, then add 3.3 parts of film-forming aid, wetting and leveling agent 0.1 part, thickener 0.1 part, that is.

[0057] The fungicide is a Kason fungicide from Shenzhu Chemical Company, brand name SN-B9720.

[0058] The anti-sedimentation agent is fumed silica, trade name A200 from Evonik.

[0059] The pH regulator is ammonia water with a concentration of 10%.

[0060] The defoamer is a silicone type defoamer, Puwei Company, brand DF-1901.

[0061] The dispersant is polymer dispersant, BYK chemical company, brand BYK-190.

[0062] ...

Embodiment 3

[0067] Take 13 parts of water, 0.1 part of fungicide, 0.06 part of anti-settling agent, 0.1 part of pH regulator, 1 part of defoamer, 0.5 part of dispersant, 8 parts of titanium dioxide, 0.5 part of iron oxide black, 0.2 part of iron oxide yellow, acrylic acid Add 45 parts of resin, 7 parts of barium sulfate, 10 parts of feldspar powder, and 5 parts of mica powder into the dispersing tank in sequence. After stirring evenly, grind to a fineness of 45 μm, then add 2.8 parts of film-forming aids, wetting and leveling agent 0.1 part, thickener 0.05 part, that is.

[0068] The fungicide is Kasone fungicide, brand 342 from Fengtian Chemical Company.

[0069] The anti-sedimentation agent is attapulgite clay, brand U-400 from Lanya Company.

[0070] The pH regulator is isopropanolamine.

[0071] The defoaming agent is an organosilicon type defoaming agent, which is Shenzhu Chemical Company, and the brand name is SN-6791.

[0072] The dispersant is a polymer dispersant, Simpson Comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com