A kind of conductive silver glue and its preparation method and application

A technology of conductive silver glue and silver nanosheets, which is applied in the field of conductive glue, can solve the problem that the conductive silver glue cannot be stretched, and achieve the effects of simple formula and production process, fast curing speed and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

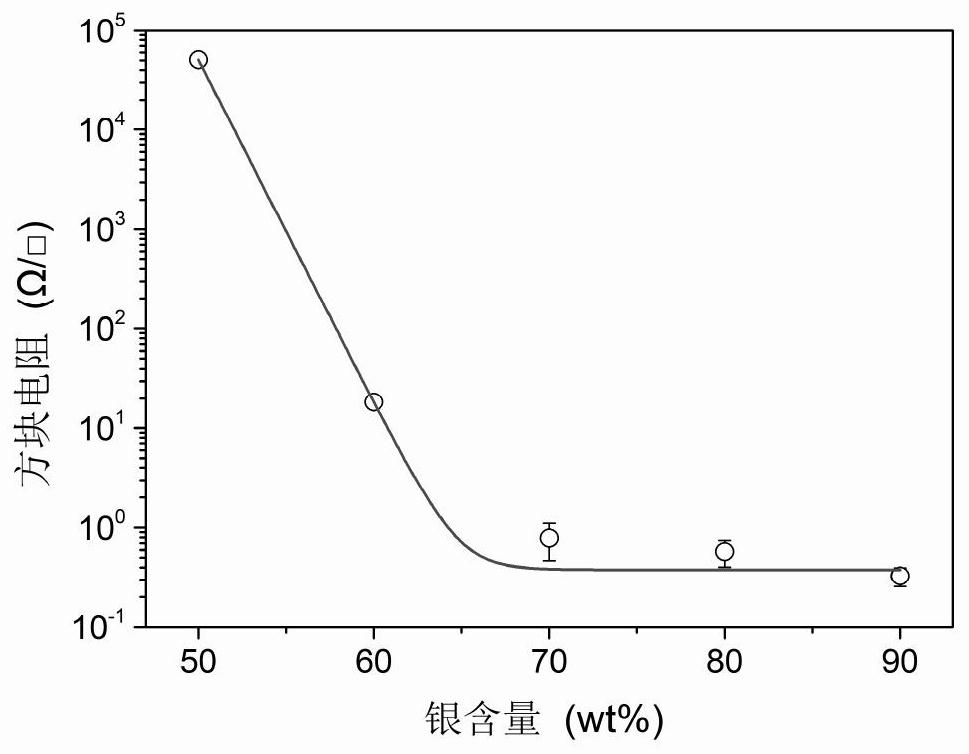

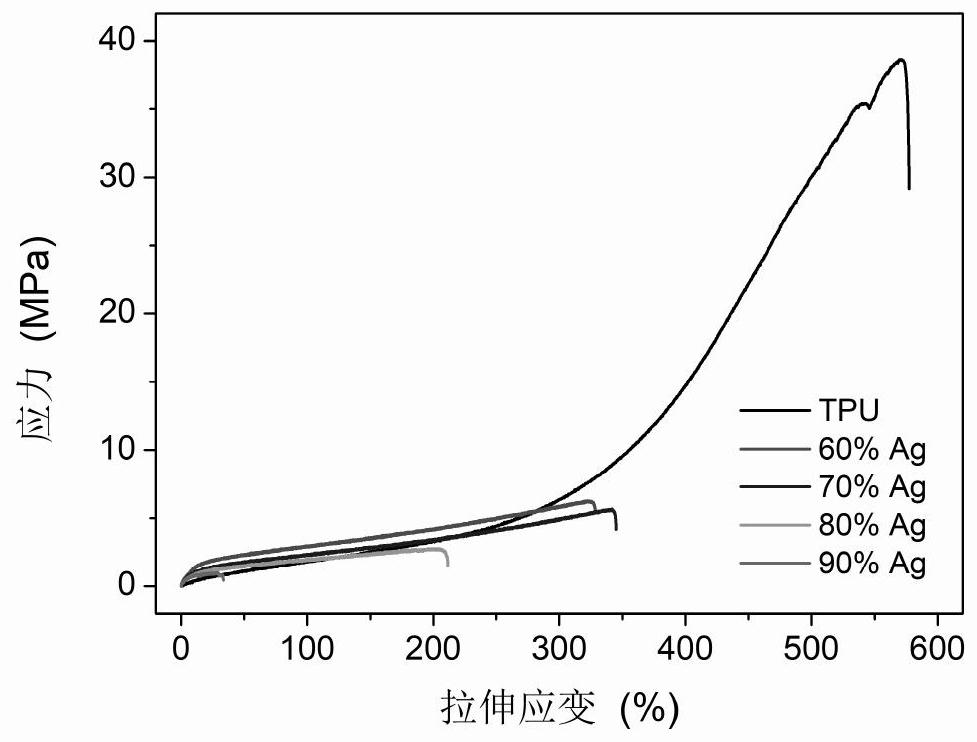

[0030] Embodiment 1 Based on the total weight of silver nanosheets and low modulus polymer, silver nanosheets account for 70wt%

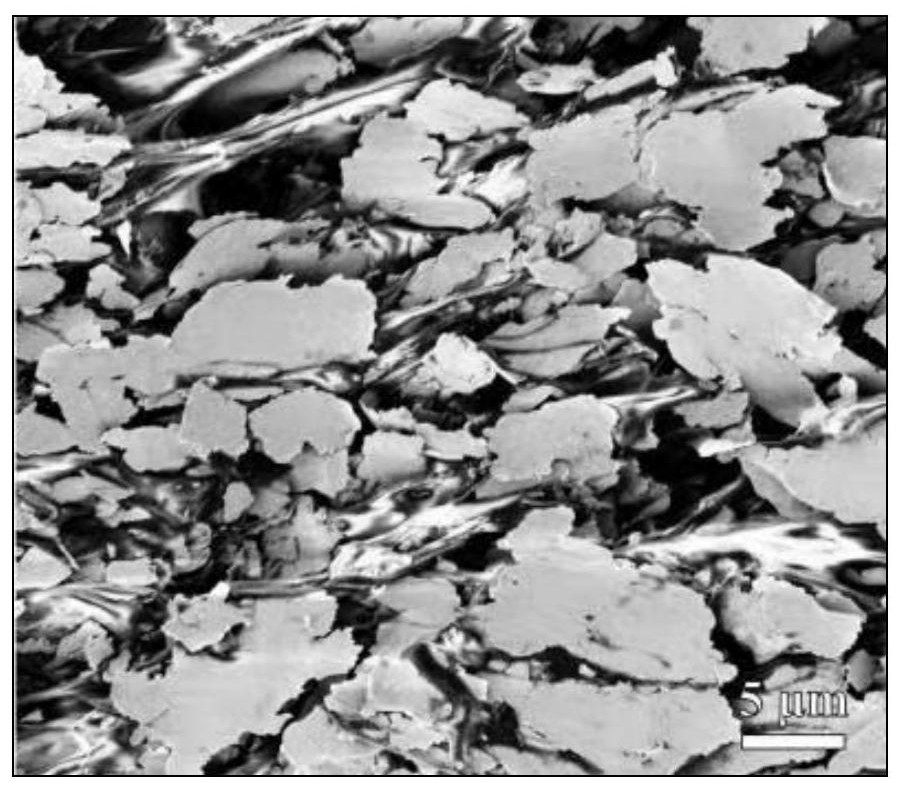

[0031] Silver nanosheets with a diameter of about 2 μm and a thickness of 5 to 10 nm were selected as conductive fillers, thermoplastic polyurethane elastomer TPU was used as the elastomeric polymer (Germany BASF 35A polyurethane), and dimethylformamide DMF was used as the organic solvent , TPU and DMF are first mixed in a weight ratio of 1:4, and then silver nanosheets and TPU are mixed in a weight ratio of 7:3. After fully stirring, a flexible sensor and wire for connecting PMDS elastomers can be obtained. Conductive silver paste. The SEM of the conductive silver glue after curing see figure 1 . Put the conductive silver paste between the wire and the flexible sensor electrode, volatilize the DMF at room temperature, and it will be completely volatilized within half an hour. The wire and the electrode are firmly connected, and the contact resist...

Embodiment 2

[0034] Embodiment 2 Based on the total weight of silver nanosheets and low modulus polymers, silver nanosheets account for 80wt%

[0035] Silver nanosheets with a diameter of about 2 μm and a thickness of 5 to 10 nm were selected as conductive fillers, thermoplastic polyurethane elastomer TPU was used as the elastomeric polymer (German BASF 35A polyurethane), dimethylformamide DMF was used as the organic solvent, and TPU Mix it with DMF at a weight ratio of 1:1.5, and then mix silver nanosheets and TPU at a weight ratio of 8:2. After fully stirring, it is used to 3D print patterned electrodes on flexible substrates. The conductive silver paste formulated with a high molecular polymer carrier with a weight ratio of TPU to DMF of 1:1.5 has increased viscosity, which can not only be smoothly extruded from the 3D printing nozzle, but also will not flow on the printed substrate, ensuring the pattern completeness and accuracy. At the same time, due to the reduced specific gravity o...

Embodiment 3

[0036] Embodiment 3 Based on the total weight of silver nanosheets and low modulus polymer, silver nanosheets account for 90wt%

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com